Oct . 16, 2024 07:59 Back to list

hdpe pipe couplings factory

Understanding HDPE Pipe Couplings A Comprehensive Overview of Factories and Manufacturing

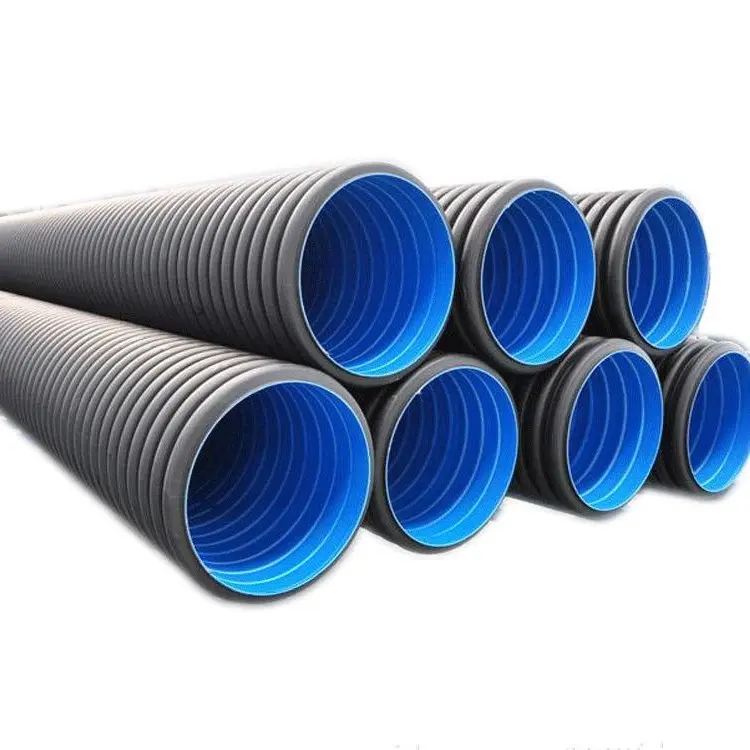

High-Density Polyethylene (HDPE) has revolutionized the piping industry due to its outstanding physical and chemical properties. One of the crucial components in HDPE piping systems is the coupling, which plays a significant role in connecting different sections of pipes. This article explores the importance of HDPE pipe couplings and delves into the manufacturing processes of factories that specialize in their production.

Understanding HDPE Pipe Couplings A Comprehensive Overview of Factories and Manufacturing

Manufacturing HDPE pipe couplings requires advanced technology and precision engineering. Facilities dedicated to producing these couplings typically utilize state-of-the-art machinery, including extrusion and injection molding equipment. The process begins with the procurement of high-quality HDPE resin, which is then melted and shaped into the desired coupling forms. After shaping, the couplings undergo rigorous quality control assessments to ensure they meet industry standards and specifications.

hdpe pipe couplings factory

The production process involves several steps, including extrusion, molding, and testing. During extrusion, the HDPE resin is heated to a specific temperature and forced through a die to create a continuous profile of the coupling. Once the extruded form is cooled and solidified, it may be cut to specific lengths. Alternatively, in injection molding, the resin is injected into molds to create more complex shapes and designs. This method allows for better precision and can accommodate a variety of coupling designs.

Quality control is a critical aspect of manufacturing HDPE pipe couplings. Factories employ various testing methods, such as tensile strength tests, pressure testing, and visual inspections, to ensure the products meet the required safety and performance criteria. This commitment to quality ensures that the couplings will perform reliably under the demanding conditions of their applications.

Moreover, as sustainability becomes increasingly crucial in manufacturing, many HDPE coupling factories are adopting eco-friendly practices. This includes using recycled HDPE materials and implementing energy-efficient processes. By doing so, they not only reduce waste but also contribute to a more sustainable future in the piping industry.

In conclusion, HDPE pipe couplings play an essential role in the functionality and reliability of piping systems. The factories that manufacture these couplings combine advanced technology with stringent quality control measures to produce superior products. As the demand for reliable and eco-friendly piping solutions continues to grow, the HDPE coupling industry is likely to evolve, emphasizing innovation and sustainability. This commitment to quality and environmental responsibility ensures that HDPE couplings will remain a staple in modern piping applications for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025