Dec . 12, 2024 09:21 Back to list

hdpe pipe cost products

Understanding HDPE Pipe Cost Products

High-Density Polyethylene (HDPE) pipes are widely recognized for their durability, flexibility, and resistance to various environmental factors. These pipes have become essential in numerous applications, including water supply, sewage systems, and industrial setups. As demand for HDPE pipes grows, so does the interest in understanding the associated costs and the factors influencing them.

Factors Influencing HDPE Pipe Costs

1. Material Quality The quality of the HDPE material significantly impacts the cost. Higher-grade HDPE resins may come at a premium but provide enhanced durability, UV resistance, and longevity, making them a cost-effective choice over time.

2. Pipe Diameter and Thickness The size of the HDPE pipe directly influences its price. Larger diameter pipes require more material and can add to production costs. Similarly, the thickness of the pipe wall, which is essential for determining the pressure rating, can affect pricing.

3. Manufacturing Processes Different manufacturing processes can lead to variations in pipe costs. Advanced technologies that ensure precision and quality can be more expensive, although they may result in better performance and lower long-term maintenance costs.

4. Regulatory Standards Compliance with national and international standards can also impact costs. Pipes that meet stringent quality standards may incur higher manufacturing expenses, which are then reflected in retail prices.

5. Market Demand Like any commodity, the cost of HDPE pipes is subject to market dynamics. Increased demand driven by infrastructure projects or environmental regulations can lead to price hikes. Conversely, a decline in demand can result in lower costs.

6. Transportation and Logistics The cost of transporting HDPE pipes from manufacturers to end-users can add significantly to the overall price. Geographic location, shipping methods, and local regulations can influence logistics costs.

hdpe pipe cost products

7. Installation and Labor Beyond the material and manufacturing costs, the expense of installing HDPE pipes should be considered. Proper installation requires skilled labor, and the complexity of the installation process can vary significantly based on the project scale.

Price Range of HDPE Pipes

Due to the various factors above, the cost of HDPE pipes can vary widely. On average, prices can range from $0.50 to $3.00 per linear foot, depending on the diameter and thickness. Specialty pipes, such as those designed for specific industrial applications, could be priced higher.

Additionally, the pricing structure may exhibit variations based on purchasing bulk quantities. Many suppliers offer discounts for larger orders, making it cost-effective for contractors and large-scale projects.

Cost-Effective Alternatives

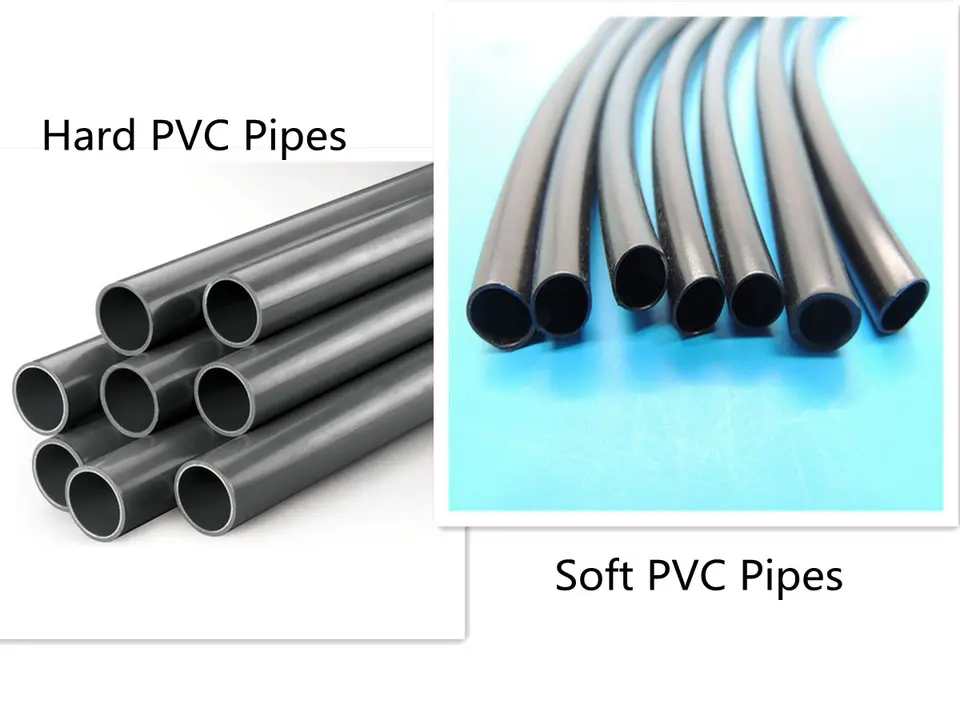

While HDPE pipes are often the preferred choice due to their performance characteristics, there are alternatives worth considering. PVC pipes, for example, are generally cheaper upfront but may not offer the same long-term durability as HDPE. For projects that require specific characteristics, such as flexural strength or chemical resistance, comparing materials based on their cost and benefits can lead to better-informed decisions.

Conclusion

In conclusion, the cost of HDPE pipes is influenced by a myriad of factors, including material quality, pipe dimensions, manufacturing techniques, and market conditions. Understanding these elements is crucial for making cost-effective choices in purchasing and installing HDPE pipes. As the proliferation of infrastructure projects continues and the demand for reliable, durable piping materials rises, HDPE pipes remain a favored option in the construction industry. Therefore, contractors and project managers must evaluate their specific needs, applicable regulations, and budget constraints to determine the most suitable HDPE pipe solutions for their projects. By considering both initialand long-term costs, stakeholders can ensure their investments yield the best return over time, contributing to more sustainable and efficient infrastructure development.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025