Nov . 05, 2024 18:30 Back to list

hdpe pipe cost product

Understanding the Cost of HDPE Pipe Products

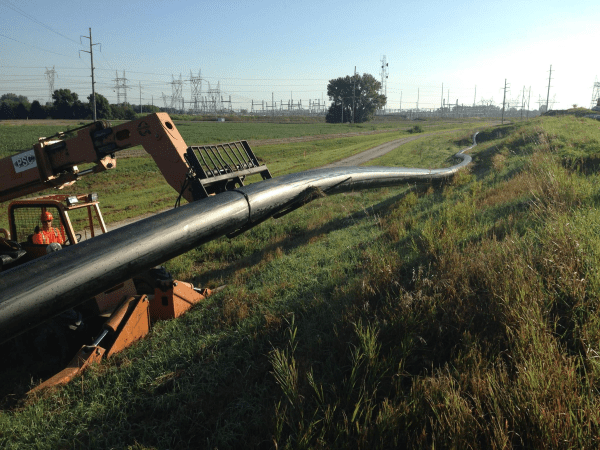

High-Density Polyethylene (HDPE) pipes have gained significant traction across various industries, including construction, agriculture, and waste management, due to their durability, lightweight nature, and resistance to corrosion. One of the most pressing questions when considering HDPE pipes for a project is the associated cost. This article delves into the factors influencing the cost of HDPE pipe products, providing insights into budgetary planning and overall investment value.

Factors Influencing the Cost of HDPE Pipes

1. Material Quality HDPE pipes are manufactured from high-quality polyethylene resin. The specific grade of resin used can significantly influence the cost. Higher quality materials tend to be more expensive but offer better longevity and performance, reducing the need for frequent replacements.

2. Pipe Diameter and Length The dimensions of the HDPE pipes themselves greatly impact their cost. Larger diameter pipes and longer lengths typically result in higher prices due to the greater volume of raw materials required for production. Companies often need to balance their need for larger pipes with the accompanying costs.

3. Manufacturing Processes The process used to manufacture HDPE pipes can also affect their pricing. Advanced manufacturing techniques, which may enhance the pipe's properties (like flexibility and strength), often come at a higher initial cost. However, these processes can lead to reduced installation costs and improved performance, ultimately offering better value.

4. Market Demand and Supply Like any other commodity, the cost of HDPE pipes can fluctuate based on market demand and supply. Economic conditions, seasonal demand (especially in agriculture), and the availability of resin can impact prices variably. Buyers might notice price increases during peak construction seasons or when there are disruptions in supply chains.

5. Transportation and Logistics The location of manufacturing facilities relative to project sites plays a significant role in transportation costs. For instance, remote projects can incur higher shipping fees, which buyers should factor into total project costs when budgeting.

6. Installation Costs While not directly related to the pipe's price, installation costs can significantly affect overall expenses. HDPE pipes are lighter than traditional materials like PVC or metal, often resulting in lower transportation and labor costs during installation. However, specialized equipment and skilled labor may be necessary for certain installations, thus affecting the overall price.

hdpe pipe cost product

Long-Term Cost Efficiency

When evaluating the cost of HDPE pipes, it’s essential to consider their long-term efficiency. Although the initial purchase price may be higher compared to some other materials, HDPE pipes can offer significant cost savings over time. Their resistance to corrosion, low friction loss, and excellent durability can lead to lower maintenance costs and fewer replacements, ultimately saving money in operational expenses.

Other long-term benefits include

- Environmental Impact HDPE pipes are recyclable, reducing waste and potentially lowering disposal costs. Their lightweight nature also means lower energy consumption during transportation.

- Resistance to Chemicals and Temperature Fluctuations HDPE pipes can handle a wide range of chemicals and temperature changes, making them ideal for various applications, including sewage, drainage, and drinking water.

- Improved Flow Rates The smooth interior of HDPE pipes allows for enhanced flow rates and reduced blockage, resulting in lower operational costs for water and wastewater systems.

Conclusion

The cost of HDPE pipe products is influenced by a multitude of factors, ranging from material quality and pipe dimensions to market conditions and installations. While the initial price can be a consideration, it's crucial for decision-makers to analyze long-term benefits and efficiencies that HDPE pipes bring to projects. By understanding these nuances, businesses can make informed decisions that align with their budget while ensuring the sustainability and reliability of their infrastructural investments. As industries continue to prioritize efficiency and cost-effectiveness, HDPE pipes will likely remain a compelling option for a wide array of applications.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025