Nov . 07, 2024 07:56 Back to list

High-Density Polyethylene Pipe Solutions for Various Industrial Applications and Projects

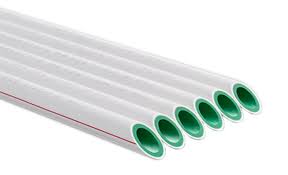

Understanding HDPE Pipe Products Benefits and Applications

High-Density Polyethylene (HDPE) pipes have become a cornerstone in various industries due to their superior properties and versatility. Companies specializing in HDPE pipe products cater to an array of applications ranging from water supply and irrigation to industrial operations and infrastructure projects. In this article, we will explore the characteristics, benefits, and applications of HDPE pipes, underscoring their significance in modern engineering and construction.

What is HDPE?

High-Density Polyethylene (HDPE) is a thermoplastic polymer made from petroleum. It is known for its high strength-to-density ratio, which makes it exceptionally durable and resistant to impact and chemicals. This resilience enables HDPE pipes to withstand harsh environmental conditions, making them ideal for various applications in construction and agriculture.

Key Benefits of HDPE Pipes

1. Durability and Longevity One of the most significant advantages of HDPE pipes is their longevity. They can last for over 50 years with proper care and installation. This durability translates to lower maintenance costs over time, as they are less likely to corrode or rust compared to traditional materials like metal or concrete.

2. Corrosion Resistance HDPE pipes are highly resistant to corrosion and chemicals, making them suitable for transporting abrasive and corrosive substances. This characteristic is particularly valuable in industries such as mining, sewage, and chemical processing, where other materials might fail.

3. Flexibility and Lightweight Unlike rigid piping systems, HDPE pipes are flexible, which allows them to be installed in a variety of configurations and terrains. Their lightweight nature facilitates easier handling and installation, reducing labor costs and timeframes.

4. Environmental Impact HDPE is a recyclable material, which minimizes the environmental impact of its production and use. Many HDPE pipe manufacturers implement sustainable practices throughout the production process, including minimizing waste and energy consumption. Additionally, the longevity of HDPE pipes means fewer replacements and less frequent need for new materials.

5. Cost-Effectiveness While the initial costs may vary depending on the application, the overall lifecycle cost of HDPE piping systems tends to be lower due to their durability, reduced maintenance requirements, and ease of installation. This cost-effectiveness makes HDPE pipes an attractive option for project managers and investors alike.

hdpe pipe company product

Applications of HDPE Pipes

HDPE pipes are utilized across various sectors due to their adaptability and performance. Some common applications include

1. Water Supply Systems HDPE pipes are widely used in municipal water supply systems. Their ability to handle high pressures and resist corrosion makes them ideal for transporting drinking water safely.

2. Irrigation and Agricultural Use In agriculture, HDPE pipes are popular for irrigation systems. They facilitate efficient water management and help in implementing modern farming techniques, promoting sustainability and productivity.

3. Stormwater Management HDPE is also used in stormwater management systems due to its capability to control runoff and mitigate flooding. The flexibility of HDPE allows for effective drainage solutions in various geographical environments.

4. Industrial Applications Many industries, including oil and gas, mining, and chemical manufacturing, rely on HDPE pipes for safe transport of hazardous materials. Their resistance to chemicals simplifies the management of potentially dangerous substances.

5. Telecommunications In the telecommunications sector, HDPE ducts are used for underground cabling, protecting sensitive wiring from environmental factors.

Conclusion

In conclusion, HDPE pipe products represent a vital innovation in various sectors, combining durability, flexibility, and cost-effectiveness. Their benefits extend beyond economic considerations, contributing to environmental sustainability and improved infrastructure. As industries continue to seek reliable and efficient solutions, HDPE pipes are likely to play an increasingly significant role in the future of construction and maintenance. Whether it’s for urban water supply, agricultural irrigation, or industrial processes, HDPE pipes are set to remain a preferred choice for businesses and municipalities worldwide.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025