Oct . 10, 2024 05:27 Back to list

hdpe n 12 corrugated dual wall pipe factories

Understanding HDPE N-12 Corrugated Dual Wall Pipe Factories

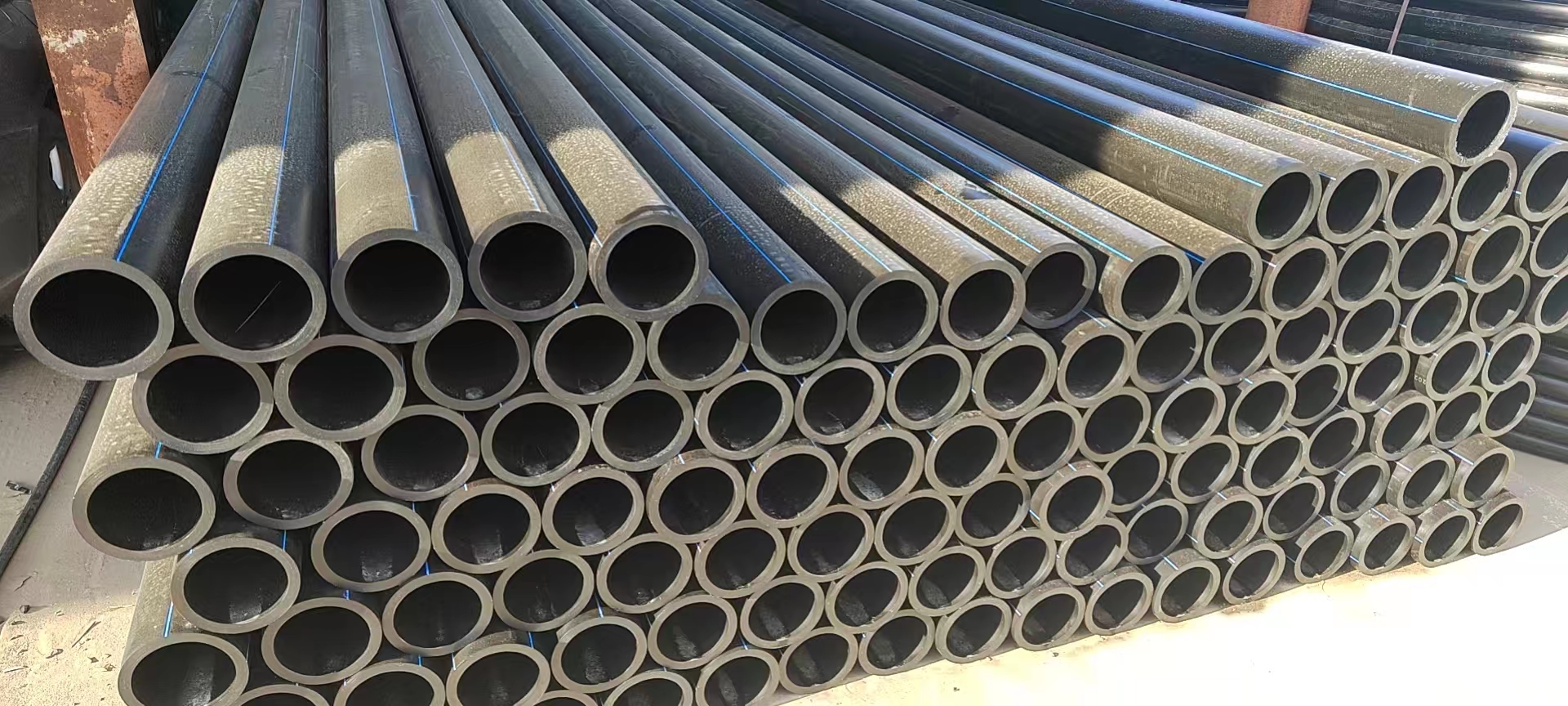

In today’s rapidly evolving industrial landscape, the demand for durable and reliable piping solutions has never been more crucial. One such solution is the High-Density Polyethylene (HDPE) N-12 corrugated dual wall pipe, which has gained significant popularity across various applications, particularly in drainage and stormwater management systems. This article delves into the manufacturing processes, benefits, and key players in the HDPE N-12 corrugated dual wall pipe industry.

What is HDPE N-12 Corrugated Dual Wall Pipe?

HDPE N-12 corrugated dual wall pipe consists of an outer corrugated layer and a smooth inner layer, combining strength and flexibility. The corrugated design enhances the pipe's structural integrity while allowing for efficient flow characteristics. The N-12 designation refers to a specific standard established by the American Association of State Highway and Transportation Officials (AASHTO), indicating that the pipe can withstand significant loads, making it suitable for various civil engineering applications.

The Manufacturing Process

Manufacturing HDPE N-12 pipes involves several key stages. First, high-quality HDPE resin is selected for its excellent tensile strength, resistance to chemical corrosion, and overall durability. The production process typically begins with the extrusion of the plastic and involves the following steps

1. Extrusion The HDPE resin is heated and melted in a barrel and then forced through a die to form the pipe shape. During this phase, the corrugated outer wall is created to provide extra strength.

2. Cooling Once the desired shape is formed, the newly extruded pipe is cooled, usually by passing it through a water bath. This cooling process ensures that the pipe retains its intended structure.

3. Cutting and Quality Control After cooling, the pipe is cut to the required lengths, and quality control inspections are performed to ensure that it meets industry standards and specifications.

4. Packaging and Distribution Finally, the finished pipes are packaged and sent to distributors or directly to construction sites where they will be installed.

Advantages of HDPE N-12 Corrugated Dual Wall Pipe

The widespread use of HDPE N-12 corrugated dual wall pipes can be attributed to several significant advantages

hdpe n 12 corrugated dual wall pipe factories

- Strength and Durability The dual-wall design provides excellent resistance to external loads and impacts, making it ideal for buried applications.

- Corrosion Resistance Unlike traditional materials such as metal, HDPE is resistant to a wide range of chemicals and will not rust, ensuring longevity in various environmental conditions.

- Lightweight and Easy to Install HDPE pipes are significantly lighter than their concrete or steel counterparts, reducing transportation costs and making them easier to handle during installation.

- Cost-Effectiveness The overall lifecycle cost of HDPE pipes is often lower than traditional materials, considering their durability and reduced maintenance needs.

Key Players and Facilities

Several factories around the world specialize in the production of HDPE N-12 corrugated dual wall pipes. These factories often invest in advanced technologies and production techniques to ensure that they manufacture high-quality products that meet stringent industry standards. Some notable manufacturers include

- Advanced Drainage Systems, Inc. (ADS) A leading manufacturer of water management solutions, ADS offers a variety of HDPE products, including N-12 pipes.

- Hancor, Inc. Known for their innovative drainage solutions, Hancor also produces corrugated dual wall pipes that meet the N-12 specifications.

- Blue Diamond Industries This company is recognized for its commitment to sustainable practices and quality products in the piping sector.

Conclusion

In summary, HDPE N-12 corrugated dual wall pipes have revolutionized the plumbing and civil engineering industries with their unique design and remarkable properties. As demand for sustainable and efficient infrastructure continues to grow, the factories producing these essential piping solutions are poised to play a critical role in the future of construction and environmental management. Understanding this industry not only highlights the technological advancements in manufacturing but also paves the way for future innovations in piping solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025