Sep . 29, 2024 02:51 Back to list

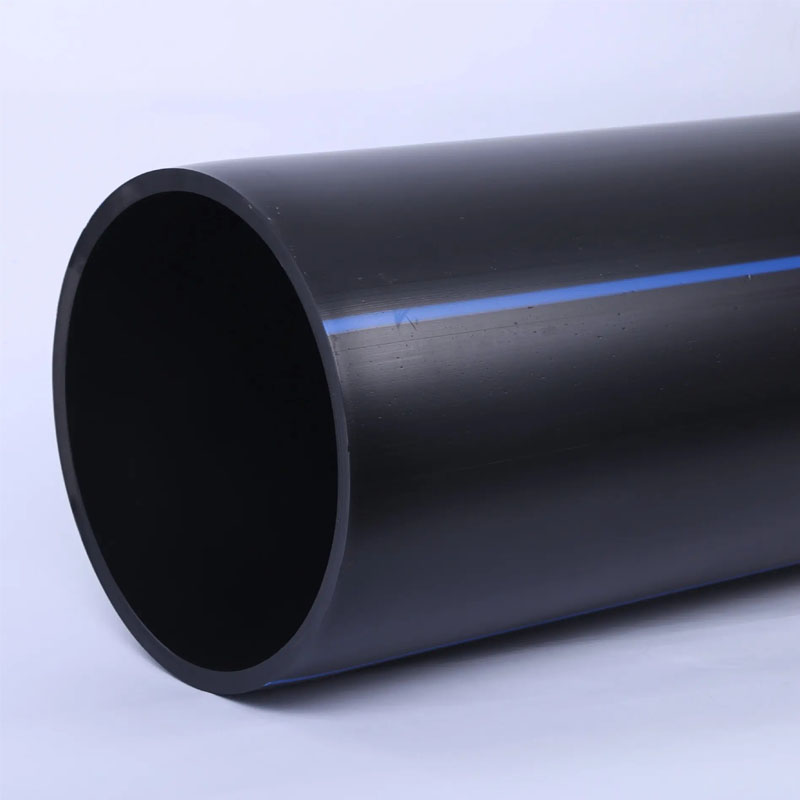

HDPE Flexible Irrigation Pipe Production by Leading Manufacturers for Efficient Water Management

The Advancements and Benefits of HDPE Flexible Irrigation Pipe Manufacturing

In the realm of modern agriculture, the demand for efficient water management systems has become increasingly critical. Farmers across the globe are continuously seeking innovative solutions that can optimize irrigation practices, conserve water, and enhance crop yields. Among the various irrigation technologies available today, High-Density Polyethylene (HDPE) flexible irrigation pipes have emerged as a leading choice for growers looking to upgrade their irrigation infrastructure. This article delves into the characteristics, manufacturing processes, and benefits of HDPE flexible irrigation pipes, as well as the leading manufacturers in this domain.

The Characteristics of HDPE Flexible Irrigation Pipes

HDPE is a thermoplastic polymer known for its durability, flexibility, and resistance to environmental stress. HDPE flexible irrigation pipes are designed to withstand harsh agricultural conditions, making them ideal for various irrigation techniques, including drip, sprinkler, and surface irrigation systems.

One of the standout features of HDPE pipes is their flexibility. This attribute allows them to be easily maneuvered around obstacles and fitted into various landscape configurations without the risk of breakage or deformation. Furthermore, HDPE pipes are resistant to UV radiation, abrasions, and chemical exposure, ensuring a long service life in diverse environmental conditions. Additionally, they are lightweight, which facilitates easy installation and transportation.

The Manufacturing Process of HDPE Pipes

The manufacturing of HDPE flexible irrigation pipes involves several key steps, ensuring that the final product meets the high standards required for agricultural applications.

1. Material Selection The process begins with the selection of high-quality HDPE resin, typically graded for its density and pressure ratings. This material must comply with various international standards, ensuring that it can perform effectively under the required conditions.

2. Extrusion The selected HDPE pellets are fed into an extruder where they are melted and mixed. This molten material is then forced through a die to create a continuous pipe shape. The extrusion process is critical as it determines the physical properties of the pipe, such as wall thickness and diameter.

3. Cooling and Sizing After extrusion, the continuous pipe is cooled and sized using water baths or air cooling systems. During this stage, quality checks are conducted to ensure that the dimensions meet specifications.

hdpe flexible irrigation pipe manufacturer

5. Quality Control Rigorous quality control measures are implemented throughout the manufacturing process. Various tests, including pressure and leak tests, are conducted to guarantee that the pipes are free from defects and capable of withstanding operational stresses.

Benefits of HDPE Flexible Irrigation Pipes

The advantages of using HDPE flexible irrigation pipes are manifold and can significantly impact agricultural efficiency.

1. Water Conservation By enabling precise water delivery through systems like drip irrigation, HDPE pipes help minimize water wastage. This is crucial in regions experiencing water scarcity and promotes sustainable farming practices.

2. Cost-Effectiveness Although the initial investment may be higher than traditional materials, the long-term savings from reduced water usage, lower maintenance costs, and increased crop yields make HDPE piping a financially sound choice.

3. Versatility HDPE pipes can be used in various irrigation methods and are adaptable to different crop types and field layouts, providing farmers with the flexibility needed to meet specific irrigation requirements.

4. Environmental Impact HDPE is recyclable, contributing to sustainable agricultural practices. Its durability means that fewer resources are spent on replacements and repairs, reducing waste and environmental impact over time.

Leading Manufacturers

Several manufacturers have positioned themselves at the forefront of HDPE flexible irrigation pipe production. Companies like Culvert and Advanced Drainage Systems leverage cutting-edge technology and sustainable practices to produce high-quality pipes. By focusing on innovation and efficiency, these manufacturers contribute to the broader goal of improving agricultural productivity and sustainability.

Conclusion

In conclusion, HDPE flexible irrigation pipes represent a significant advancement in irrigation technology, offering farmers a durable, efficient, and sustainable solution for water management. As agricultural demands continue to evolve, the role of innovative manufacturing practices and materials like HDPE will be critical in supporting the future of farming. With the ongoing focus on sustainability and efficiency, HDPE pipes will likely remain a cornerstone of modern irrigation systems for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025