Nov . 18, 2024 23:21 Back to list

Flexible HDPE Irrigation Pipe Manufacturing Facility for Efficient Water Management Solutions

HDPE Flexible Irrigation Pipe Factory Innovation in Water Management

In the era of modern agriculture, efficient water management is crucial for sustainable food production. One of the most promising solutions to this challenge is the use of High-Density Polyethylene (HDPE) flexible irrigation pipes. A factory dedicated to the production of these innovative pipes plays a significant role in transforming irrigation practices, enhancing productivity, and conserving precious water resources.

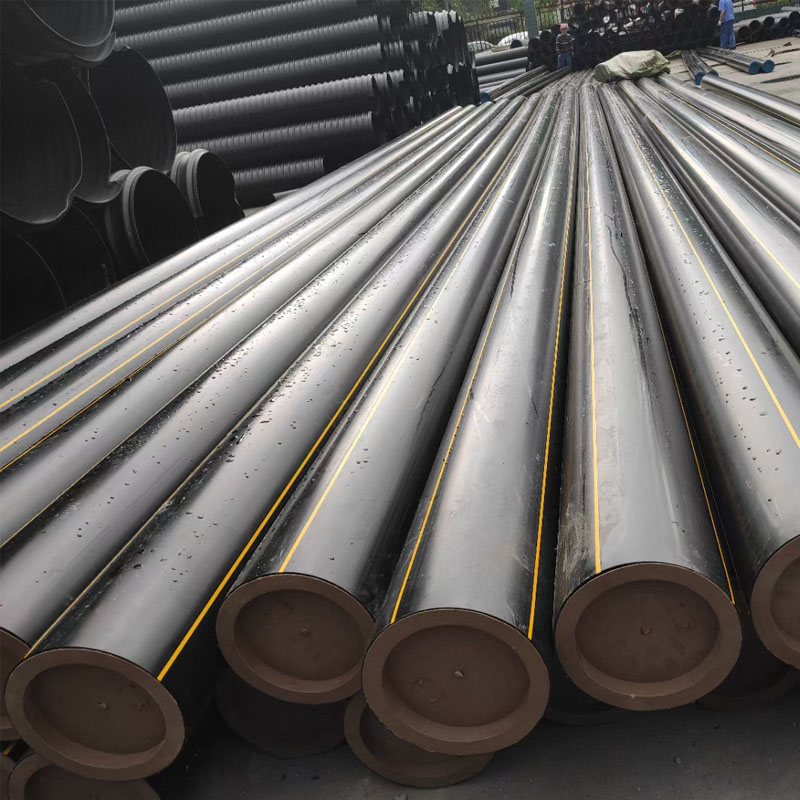

HDPE is a durable and versatile plastic known for its high tensile strength and resistance to various environmental conditions. These properties make it an ideal material for irrigation systems that need to withstand harsh weather, soil chemicals, and extreme temperatures. The manufacturing process involves polymerizing ethylene gas, which is then molded into pipes that can be easily coiled and transported, thanks to their flexibility.

The primary advantage of HDPE flexible irrigation pipes is their ability to conform to different landscapes and terrains. Unlike rigid pipes, HDPE can easily navigate uneven ground, making it suitable for a wide range of agricultural settings—from flat fields to hilly regions. This flexibility facilitates more efficient water coverage, reducing runoff and ensuring that crops receive the water they need without wastage.

hdpe flexible irrigation pipe factory

Moreover, the factory that produces HDPE flexible irrigation pipes employs advanced technology and sustainable practices. The production process prioritizes minimal environmental impact by recycling materials whenever possible and utilizing energy-efficient machinery. This commitment to sustainability not only improves the overall eco-friendliness of the manufacturing process but also resonates with the values of modern consumers who are increasingly aware of environmental issues.

Quality control is another critical aspect of the production facility. Each batch of pipes undergoes rigorous testing to ensure they meet international standards for durability and performance. The factory’s commitment to quality ensures that farmers receive reliable products that enhance their irrigation systems, ultimately leading to increased crop yields and healthier plants.

In addition to the technical advantages, the factory also plays a vital role in supporting the local economy by creating jobs and fostering innovation. By investing in research and development, the factory can stay at the forefront of irrigation technology, offering products that not only meet current agricultural needs but also anticipate future challenges, such as water scarcity and climate change.

In conclusion, an HDPE flexible irrigation pipe factory is more than just a manufacturing facility; it is a hub of innovation and sustainability in the agricultural sector. By providing farmers with high-quality irrigation solutions, it helps to optimize water usage, increase productivity, and contribute to a more sustainable future for agriculture. As water resources become increasingly scarce, the role of such factories will only grow in importance, making them pivotal players in the quest for efficient and sustainable farming practices.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025