Dec . 05, 2024 18:25 Back to list

HDPE Double-Wall Corrugated Pipe Manufacturing Process and Quality Standards

The Advancements and Applications of HDPE Double Wall Corrugated Pipe

High-Density Polyethylene (HDPE) double wall corrugated pipes have become a cornerstone in modern infrastructure development. Their unique design and material properties make them ideal for various applications, from drainage systems to sewerage networks. This article explores the manufacturing processes in factories, the advantages of using HDPE corrugated pipes, and their diverse applications in construction and civil engineering.

Manufacturing Process

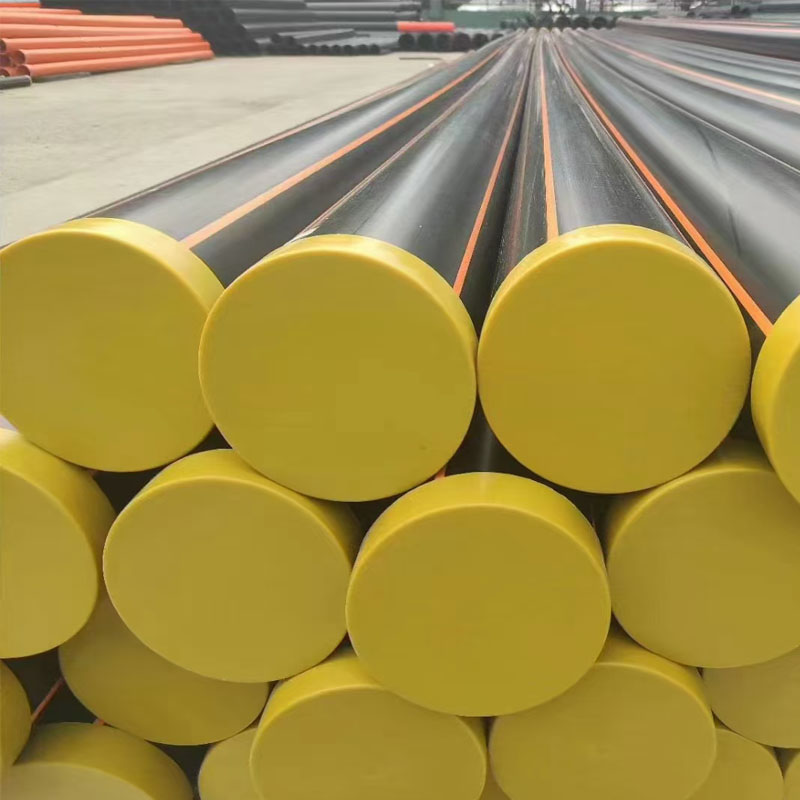

The production of HDPE double wall corrugated pipes is a sophisticated process that involves several key steps. Factories utilize advanced extrusion technology, allowing for the efficient creation of these pipes. The process generally begins with the selection of high-quality HDPE resin, which is melted and extruded through a die to form a corrugated profile.

This two-layer structure consists of an outer corrugated layer and an inner smooth layer. The outer layer provides structural strength and resistance to external loads, while the inner layer ensures smooth flow characteristics, minimizing turbulence and friction. The dual-wall design significantly enhances the pipe's durability and longevity.

Post-extrusion, these pipes undergo cooling and cutting to achieve specified lengths. Quality control is paramount, with rigorous tests conducted to ensure the pipes meet industry standards for strength, flexibility, and chemical resistance. As factories increasingly embrace automation and robotics, production efficiency and accuracy have vastly improved, enabling them to meet the growing demand for innovative piping solutions.

Advantages of HDPE Double Wall Corrugated Pipes

HDPE double wall corrugated pipes offer numerous benefits that set them apart from traditional materials. Their lightweight nature eases transportation and installation, reducing labor costs and time. Furthermore, these pipes exhibit exceptional resistance to corrosive chemicals, making them suitable for various environments, including industrial applications.

hdpe double wall corrugated pipe factory

Their flexibility allows for easy handling and installation in challenging terrains, while the dual-wall design contributes to a high load-bearing capacity. Additionally, HDPE pipes are resistant to UV radiation and have a low coefficient of friction, promoting efficient water flow with minimal maintenance. With a lifespan exceeding 50 years, they offer excellent long-term value for construction projects.

Diverse Applications

The versatility of HDPE double wall corrugated pipes makes them suitable for a wide range of applications. One of the most common uses is in stormwater management systems. These pipes effectively convey surface runoff and prevent flooding in urban areas. Their ability to withstand heavy loads makes them especially popular in roadway and highway drainage systems.

In addition to drainage applications, HDPE corrugated pipes are extensively used in sewer systems, where their corrosion resistance ensures a long-lasting solution for waste management. They are also applied in irrigation systems, offering efficient water transport for agricultural use. Industries such as mining and civil engineering utilize HDPE pipes to handle various materials, given their strength and reliability.

The increasing emphasis on sustainability and environmental responsibility has further fueled the adoption of HDPE pipes. Because these pipes are recyclable, they contribute to reducing plastic waste in landfills, aligning with global efforts toward sustainable development.

Conclusion

HDPE double wall corrugated pipes exemplify the synergy between innovation and practicality in the modern manufacturing landscape. With their robust design, lightweight properties, and resistance to environmental stresses, these pipes have revolutionized various sectors, including construction, agriculture, and waste management. As the demand for reliable and sustainable solutions continues to grow, the role of HDPE double wall corrugated pipes in infrastructure development will undoubtedly expand, leading to more efficient and eco-friendly practices worldwide. Their availability from dedicated factories ensures that industries have access to high-quality products that meet the ever-evolving needs of society.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025