Dec . 05, 2024 15:31 Back to list

hdpe coupling joint products

An Overview of HDPE Coupling Joint Products

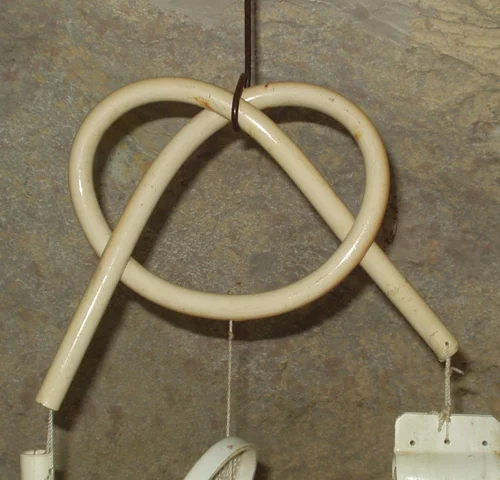

High-Density Polyethylene (HDPE) has emerged as one of the most versatile and durable materials used in a variety of industries, particularly in piping systems. One specific aspect of HDPE piping systems is the coupling joint, an essential component that allows for the connection and extension of pipes, offering a seamless flow of liquids or gases. This article delves into the significance, features, and applications of HDPE coupling joint products.

What is HDPE?

HDPE is a thermoplastic polymer made from petroleum. Known for its high strength-to-density ratio, HDPE exhibits remarkable durability, chemical resistance, and temperature resilience. Due to these properties, it is widely used in construction, agriculture, and waste management sectors among others. The ability of HDPE to withstand harsh environmental conditions makes it the preferred choice for piping systems in various applications.

Importance of HDPE Coupling Joints

Coupling joints are critical in ensuring the integrity and efficiency of a piping system. They enable pipes to connect seamlessly, facilitating uninterrupted flow while minimizing the risk of leaks. Given that HDPE pipes are often used in applications that require long runs, such as water supply lines, irrigation systems, and gas distribution, the quality of the coupling joints is paramount.

The primary roles of HDPE coupling joints include

1. Connection HDPE coupling joints allow for the coupling of two separate lengths of HDPE pipe, making it possible to create longer pipeline systems without compromising on strength or fluid dynamics.

2. Flexibility Given the nature of many installation environments, coupling joints provide flexibility, allowing pipes to expand and contract with temperature changes while maintaining a secure connection.

3. Leak Prevention High-quality HDPE coupling joints are designed to prevent leaks, which is essential for both environmental safety and operational efficiency.

4. Ease of Installation HDPE coupling joints can often be installed using basic tools and techniques, facilitating quicker and more cost-effective assembly. This ease of installation can significantly reduce labor costs and time.

Types of HDPE Coupling Joints

HDPE coupling joints come in various designs, each suited to particular applications

hdpe coupling joint products

1. Socket Fusion Couplings This type involves heating the ends of the pipes and the coupling, then joining them together. Socket fusion fittings provide robust connections that are particularly effective for smaller diameter pipes.

2. Electrofusion Couplings These couplings utilize electric current to heat and fuse the pipes. They are popular in larger HDPE installations because they offer a strong joint and are ideal for environments where traditional welding might be challenging.

3. Mechanical Couplings Mechanical HDPE couplings allow the connection of pipes without the need for welding. They use mechanical means to create a secure joint and are particularly useful for quick repairs or modifications in existing systems.

4. Butt Fusion Couplings This method involves fusing the ends of the pipes together using heat. Butt fusion is typically used for larger diameter pipes and can create a permanent joint that is as strong as the pipe itself.

Applications of HDPE Coupling Joints

The versatility of HDPE coupling joint products leads to their widespread use across various industries

1. Water Supply Systems HDPE pipes and coupling joints are extensively used in municipal water supply and wastewater management systems due to their resistance to corrosion and ability to handle varying water pressures.

2. Irrigation In agriculture, HDPE coupling joints are used in irrigation systems to connect long stretches of pipe, ensuring efficient water distribution across fields.

3. Gas Distribution The natural gas industry utilizes HDPE piping systems, and coupling joints play a crucial role in maintaining gas flow and pressure integrity.

4. Industrial Applications Many industrial settings, including chemical processing plants, require reliable pipe connections that can handle corrosive substances; thus, HDPE coupling joints are ideal.

Conclusion

HDPE coupling joint products represent a vital component of modern piping systems. Their design, versatility, and reliability make them indispensable across various applications. As industries continue to evolve, the demand for efficient and robust coupling solutions will undoubtedly grow, cementing the role of HDPE products in future infrastructure development. By using high-quality HDPE coupling joints, businesses can ensure efficient operations, safety, and sustainability in their projects.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025