Oct . 15, 2024 02:30 Back to list

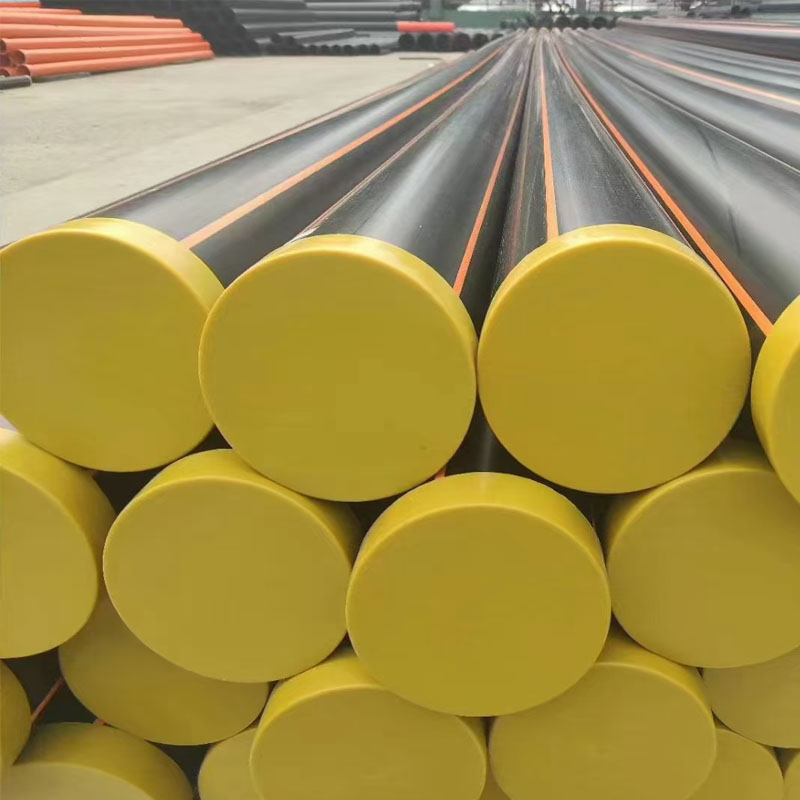

HDPE Coupling Fittings for Durable and Reliable Pipeline Connections in Various Applications

Understanding HDPE Coupling Fittings A Comprehensive Guide

High-Density Polyethylene (HDPE) has become a vital material in various industries due to its impressive properties such as durability, flexibility, and resistance to chemicals. Among the essential components in HDPE piping systems, HDPE coupling fittings play a pivotal role in ensuring seamless connections, maintaining system integrity, and facilitating effective fluid transport. This article delves into the significance, types, applications, and advantages of HDPE coupling fittings.

What Are HDPE Coupling Fittings?

HDPE coupling fittings are connectors used to link two sections of HDPE pipes, allowing for the smooth and efficient flow of liquids or gases. These fittings are crucial in numerous applications where pipeline systems need to be extended or repaired without compromising performance. HDPE coupling fittings are designed to withstand high pressure and harsh environmental conditions, making them ideal for various industries, including water distribution, wastewater management, gas distribution, and chemical processing.

Types of HDPE Coupling Fittings

There are several types of HDPE coupling fittings that cater to different needs

1. Straight Couplings These are the most common type of coupling fittings, used to connect two pipes of the same diameter directly. They facilitate quick and easy repairs or extensions of existing pipe systems.

2. Reducing Couplings These fittings are designed to connect pipes of different diameters, enabling transitions from a larger pipe to a smaller one while maintaining a seamless flow.

3. Elbow Couplings Used to change the direction of the pipe, elbow couplings come in standard angles, such as 45 or 90 degrees. These are essential for navigating around obstacles or fitting into existing layouts.

4. Tee Couplings These fittings allow for branching off from a main pipe, facilitating the distribution of fluid to additional lines. Tee couplings are invaluable in complex piping systems.

5. Cap Fittings Cap fittings are used to close the end of a pipe. They are often used in systems where the end points are not actively transporting fluids but may require access for maintenance or inspection.

Applications of HDPE Coupling Fittings

HDPE coupling fittings find applications across various sectors, including

hdpe coupling fittings product

- Water Supply Systems In municipal water distribution networks, HDPE couplings ensure reliable connections that resist leaks and pipe bursts.

- Wastewater Management In sewer systems, these fittings play a crucial role in maintaining system integrity and preventing environmental contamination.

- Gas Distribution The robust nature of HDPE fittings makes them suitable for transporting natural gas, ensuring safety and efficiency.

- Irrigation Systems In agriculture, HDPE coupling fittings facilitate the efficient delivery of water to crops, crucial for maximizing yield.

Advantages of Using HDPE Coupling Fittings

1. Durability HDPE is resistant to corrosion, ultraviolet light, and impact damage, leading to a longer lifespan compared to traditional materials.

2. Flexibility The flexibility of HDPE allows for easy installation and adaptability in varied terrains, making it ideal for outdoor projects.

3. Cost-Effectiveness Although the initial investment may be slightly higher, the long-term savings on maintenance and replacement costs make HDPE coupling fittings a cost-effective choice.

4. Easy Installation Many HDPE coupling fittings feature simple joining methods such as heat fusion or electrofusion, minimizing labor time and effort during installation.

5. Environmental Impact HDPE is recyclable and significantly reduces environmental footprints in construction and maintenance, promoting sustainability.

Conclusion

HDPE coupling fittings are indispensable components of modern piping systems, providing reliable connections that enhance the overall performance of fluid transport systems. Their versatility, durability, and ease of installation make them the preferred choice for engineers and contractors alike. As industries continue to prioritize sustainability and efficiency, the role of HDPE materials, particularly coupling fittings, will only become more pronounced in the years to come. Whether for water supply, gas distribution, or irrigation purposes, understanding and utilizing HDPE coupling fittings is essential for optimal system performance and longevity.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025