Nov . 09, 2024 17:18 Back to list

Affordable HDPE Coupler Pricing and Product Overview for Your Projects

Understanding HDPE Coupler Prices A Comprehensive Overview

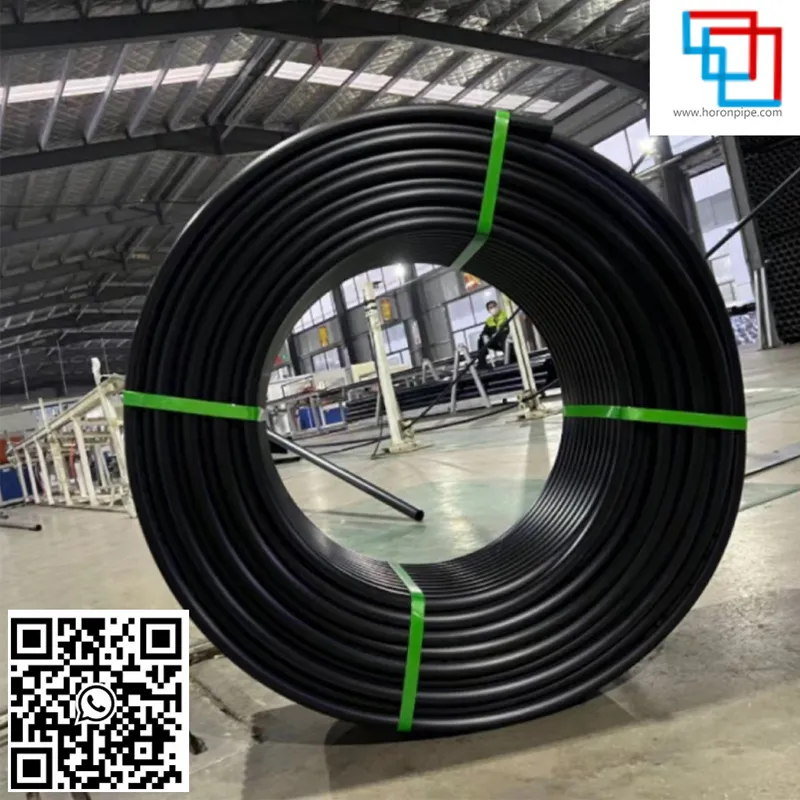

When it comes to piping systems, the choice of materials and connection methods plays a significant role in ensuring efficiency, durability, and cost-effectiveness. High-Density Polyethylene (HDPE) pipes are widely recognized for their strength, flexibility, and resistance to corrosion, making them ideal for various applications ranging from water supply to industrial uses. A crucial component in these systems is the HDPE coupler, which serves as a connector between two sections of HDPE pipe. This article will delve into the factors influencing HDPE coupler prices, the advantages of using HDPE couplers, and tips for purchasing them.

Factors Influencing HDPE Coupler Prices

1. Material Quality The quality of the HDPE used in the couplers directly impacts the price. High-grade HDPE offers superior durability and resistance to environmental stressors, which can result in a higher initial cost. However, investing in high-quality materials often translates to longer service life and reduced maintenance costs.

2. Size and Diameter HDPE couplers come in various diameters to accommodate different pipe sizes. Typically, larger couplers are more expensive due to the additional material required and the complexity of their manufacturing process. Consequently, specifying the correct size for your needs is essential for budgeting purposes.

3. Brand and Manufacturer Just like many other products, the brand can influence the price. Established manufacturers with a strong reputation for quality and reliability may charge a premium for their products. However, choosing reputable brands can also provide assurance regarding the durability and performance of the coupler.

4. Manufacturing Process The method employed to manufacture HDPE couplers can also affect costs. For instance, injection molding and extrusion processes have different cost structures that can impact the final price of the product. Factors such as production volume and labor costs also play a role in overall pricing.

5. Market Conditions Fluctuations in the market, including raw material availability and demand for HDPE products, can lead to changes in pricing. Global economic trends, supply chain disruptions, and local demand can all influence how much you can expect to pay for HDPE couplers at any given time.

6. Custom Designs In some cases, custom-designed couplers may be necessary to meet specific project requirements. Customization often comes with increased costs, as it involves more complex manufacturing processes and the need for specialized tooling.

Advantages of Using HDPE Couplers

1. Strong Connections HDPE couplers create strong, leak-free connections between pipes, enhancing the overall integrity of the piping system.

hdpe coupler price product

2. Corrosion Resistance One of the most significant advantages of HDPE is its resistance to corrosion. HDPE couplers maintain this characteristic, ensuring that the connections will not weaken or degrade over time.

4. Ease of Installation HDPE couplers are designed for quick and easy installation, reducing labor costs and time spent on project completion.

5. Environmental Impact HDPE is recyclable, making couplers an environmentally friendly choice for piping systems.

Tips for Purchasing HDPE Couplers

1. Research Vendors Before making a purchase, research various suppliers to compare prices, quality, and customer reviews. This can help you identify reputable vendors that offer competitive pricing.

2. Bulk Purchases If you have a large project, consider buying in bulk to take advantage of discounts. Many suppliers offer reduced rates for bulk orders.

3. Consult Professionals If you are unsure about which type of coupler to choose, consulting with a plumbing or piping expert can provide valuable insights and help you make an informed decision.

4. Check for Certifications Ensure that the couplers meet industry standards and have the necessary certifications to guarantee their quality and performance.

5. Warranty and Support Look for products that come with a warranty and reliable customer support, as this can provide peace of mind in the event of defects or issues.

In conclusion, understanding the factors that influence HDPE coupler prices can help consumers make informed purchasing decisions. With their numerous advantages and applications, HDPE couplers remain a popular choice in various industries, and selecting the right product is essential for optimizing performance and cost-effectiveness in piping systems.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025