Nov . 20, 2024 17:45 Back to list

hdpe coupler price manufacturers

Understanding HDPE Coupler Prices and Manufacturers

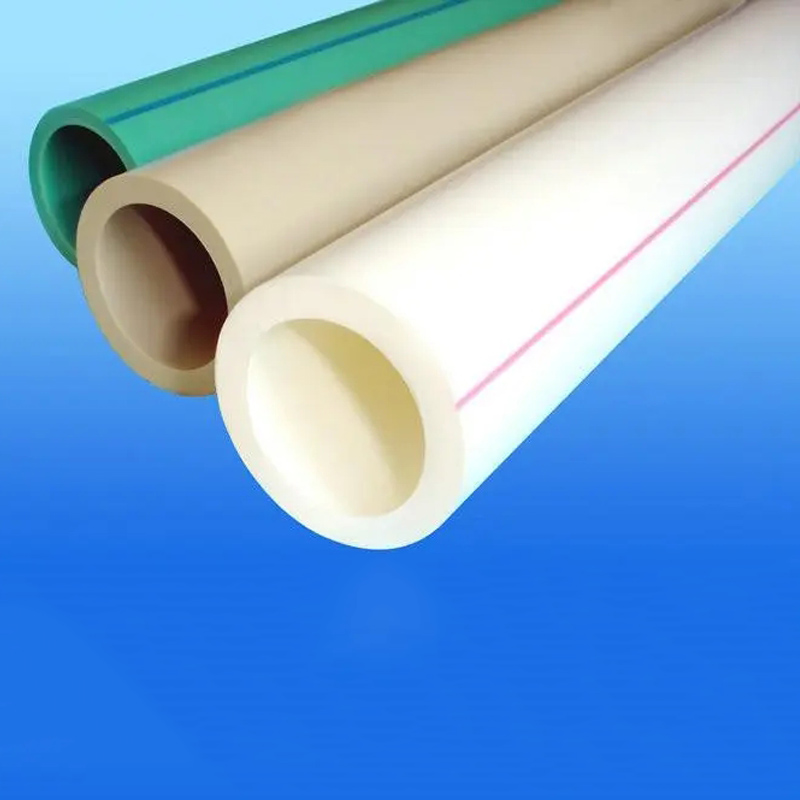

High-Density Polyethylene (HDPE) couplers are critical components in various industries, particularly in construction, plumbing, and industrial applications. These fittings are used to connect HDPE pipes, ensuring a secure and leak-proof connection that is essential for the efficient transportation of liquids and gases. As demand for HDPE products continues to rise due to their durability and resistance to environmental factors, it becomes imperative to understand the pricing dynamics and key manufacturers in this market.

Factors Affecting HDPE Coupler Prices

1. Material Quality The quality of materials used in manufacturing HDPE couplers plays a significant role in determining prices. Couplers made from virgin HDPE typically cost more than those made from recycled materials. Virgin HDPE offers superior strength and longevity, making it more suitable for high-pressure applications, which justifies its higher price.

2. Manufacturing Process The method used in the production of HDPE couplers can impact their price. Advanced manufacturing processes, such as injection molding and extrusion, may incur higher costs due to the technology and energy required. Manufacturers employing cutting-edge techniques often produce higher-quality products, which can lead to increased prices.

3. Size and Specifications HDPE couplers come in various sizes and specifications tailored to fit specific applications. Larger couplers or those designed for high-pressure systems typically have a higher price point. Custom sizes and specifications may incur additional costs, reflecting the complexity of production.

4. Market Demand and Supply Like any commodity, the prices for HDPE couplers are influenced by market demand and supply. A surge in construction projects or infrastructure development can lead to increased demand, thereby raising prices. Conversely, an oversupply can drive prices down.

5. Geographical Variations Prices can vary significantly across regions based on local availability, labor costs, and transportation expenses. In areas where demand is high but supplies are limited, prices may be inflated. Conversely, manufacturers located near raw material supplies or major transportation hubs may offer more competitive pricing.

Leading Manufacturers of HDPE Couplers

hdpe coupler price manufacturers

Several manufacturers dominate the HDPE coupler market, each offering a variety of products to meet different application needs. Here are a few notable players

1. GF Piping Systems A global leader in piping systems, GF Piping Systems offers a range of high-quality HDPE couplers known for their reliability and performance. Their products cater to various industries, including water supply, chemical, and gas.

2. Molex Molex specializes in high-performance connectors and is known for its innovative HDPE couplers. They focus on providing solutions that enhance safety and efficiency in fluid management systems.

3. Shawcor This company provides comprehensive solutions in pipeline coatings and specialty pipe services. Shawcor's HDPE couplers are well-regarded for their durability and are commonly used in oil and gas applications.

4. Advanced Drainage Systems (ADS) One of the largest manufacturers of HDPE drainage products, ADS offers a variety of couplers and fittings designed for stormwater management, agricultural drainage, and more. Their products are known for their environmental sustainability and efficiency.

5. Parker Hannifin A global leader in motion and control technologies, Parker offers reliable HDPE couplers that cater to various sectors including industrial and aerospace. Their commitment to innovation ensures that customers receive high-performance products.

Conclusion

Understanding the price dynamics of HDPE couplers and knowing the leading manufacturers can aid businesses in making informed purchasing decisions. Factors such as material quality, manufacturing processes, and market conditions play crucial roles in pricing. As industries continue to evolve and prioritize sustainability and efficiency, HDPE couplers will remain essential components, with manufacturers striving to innovate and meet the growing demands of the market. Buyers should consider not only the price but also the reputation and reliability of manufacturers to ensure they are investing in quality products that meet their specific needs.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025