Dec . 20, 2024 13:59 Back to list

HDPE Corrugated Pipe Manufacturing Prices and Suppliers Overview

Understanding HDPE Corrugated Pipe Prices and Manufacturers

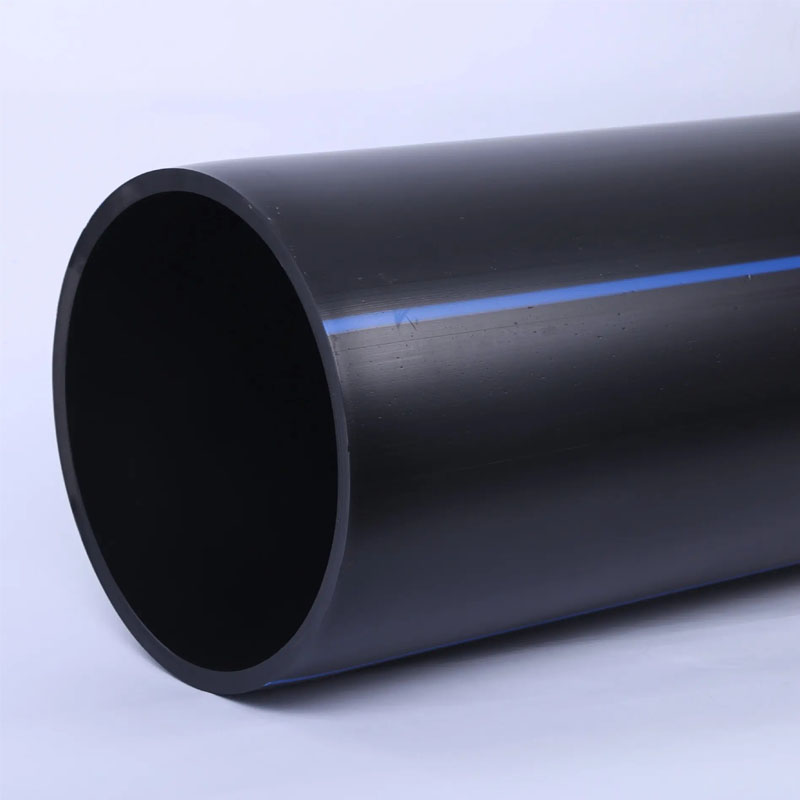

High-Density Polyethylene (HDPE) corrugated pipes have gained significant popularity in various industries due to their durability, corrosion resistance, and cost-effectiveness. These pipes are used for drainage, sewage systems, and various other applications requiring a reliable piping solution. In this article, we will explore factors influencing HDPE corrugated pipe prices and discuss key manufacturers in the market.

What is HDPE Corrugated Pipe?

HDPE corrugated pipes are composed of high-density polyethylene material that has been structurally designed to enhance strength and flexibility. The innovative design, characterized by alternating ridges and grooves, contributes significantly to its ability to withstand high pressures and environmental stresses. This makes HDPE corrugated pipe particularly suitable for drainage and waste management systems.

Factors Influencing Prices

1. Material Costs The primary contributor to the price of HDPE corrugated pipes is the cost of raw materials. Fluctuations in the price of polyethylene resin can directly affect the overall cost of production. Manufacturers tend to pass on these increased costs to consumers, which can vary substantially over time.

2. Diameter and Length The dimensions of the pipe significantly impact pricing. Larger diameter pipes require more material, which increases production costs. Furthermore, the length of the pipe also affects costs, as longer lengths typically have a higher price point.

3. Manufacturing Process The complexity of the manufacturing process, including the technology used and the production scale, can influence prices. Advanced production techniques that enhance the quality and durability of the pipes might come at a higher cost.

4. Market Demand The demand for HDPE corrugated pipes in various applications—such as infrastructure development and agricultural drainage—can lead to price fluctuations. High demand often results in elevated prices, while a slump in demand may lead to price reductions.

5. Supply Chain Factors Transportation costs, tariffs, and regional supply chain dynamics also play a significant role in determining prices. The logistics involved in getting products from manufacturers to end-users can influence final pricing, especially in areas with limited access to suppliers.

hdpe corrugated pipe price manufacturer

Key Manufacturers of HDPE Corrugated Pipes

Several prominent manufacturers specialize in producing HDPE corrugated pipes, catering to various industries. Here are a few notable companies

1. ADS (Advanced Drainage Systems) A leader in the manufacturing of water management products, ADS produces a wide range of HDPE corrugated pipes tailored for different applications. They are known for their innovative solutions and commitment to sustainability.

2. Hancor Hancor, a subsidiary of Advanced Drainage Systems, focuses on providing high-quality corrugated drainage pipe systems. They boast an extensive range of pipes suitable for both residential and commercial applications, emphasizing durability and efficiency.

3. Contech Engineered Solutions Contech excels in providing engineered solutions for infrastructure applications, including HDPE corrugated pipes. Their products are designed for optimal performance and reliability, making them a trusted choice for engineers and contractors.

4. IL & FS Environment Operating in India, IL & FS Environment promotes sustainable development through its environmental solutions, including HDPE pipes. They are recognized for their contributions to improving water management practices.

5. Northern Pipe Products Known for its commitment to quality, Northern Pipe Products manufactures a range of plastic pipe products, including HDPE corrugated pipes. Their focus on customer satisfaction and industry standards has established them as a reputable manufacturer.

Conclusion

Understanding the pricing structure of HDPE corrugated pipes is essential for anyone looking to invest in piping solutions for drainage or waste management systems. By considering the various factors that influence prices, such as material costs, manufacturing processes, and market demand, consumers can make informed choices. Additionally, recognizing key manufacturers in the industry can help individuals and businesses source quality products for their specific needs. As the demand for reliable and sustainable piping solutions continues to grow, so too will the innovations and competitive pricing in the HDPE corrugated pipe market.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025