Dec . 12, 2024 11:04 Back to list

hdpe corrugated pipe factory

HDPE Corrugated Pipe Factory Innovations and Impact on Infrastructure

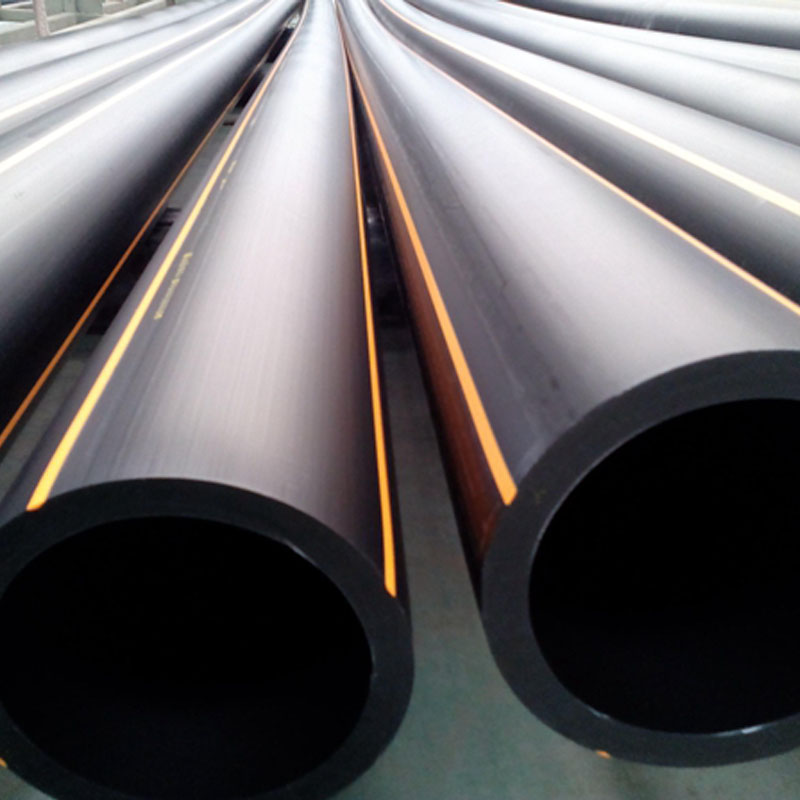

High-density polyethylene (HDPE) corrugated pipes have revolutionized the way we approach drainage systems, sewer lines, and various infrastructural projects. With the increasing demand for durable, flexible, and efficient piping solutions, HDPE corrugated pipe factories are at the forefront of this innovation. This article delves into the significance of HDPE corrugated pipes, the manufacturing process, and the advantages these products offer in modern infrastructure.

Understanding HDPE Corrugated Pipes

HDPE corrugated pipes are lightweight, yet remarkably strong and resistant to various environmental factors, such as corrosion, chemicals, and UV radiation. These pipes are primarily used for drainage, venting, and waste management applications. The corrugated design enhances their structural integrity while allowing flexibility, making them easier to transport and install compared to traditional rigid pipes. Additionally, their smooth inner walls promote efficient water flow and reduce the likelihood of blockages.

The Manufacturing Process

The production of HDPE corrugated pipes begins with high-density polyethylene resin, which is sourced and prepared meticulously. The process typically involves the following steps

1. Extrusion The HDPE resin is fed into an extruder, where it is melted and formed into a continuous profile. The extruder uses high pressure and heat to ensure that the resin flows smoothly.

2. Corrugation Once the pipe is formed, it is passed through a corrugator. This machine shapes the pipe into a series of alternating peaks and valleys, creating the corrugated structure that provides both strength and flexibility.

3. Cooling After corrugation, the pipe is cooled rapidly with water to solidify its shape. This cooling process is crucial as it ensures the pipe maintains its structural integrity for long-term use.

4. Cutting The cooled pipes are then cut into lengths according to customer specifications. Quality control checks are performed to ensure that each pipe meets industry standards and regulations.

5. Packaging and Distribution Finally, the finished pipes are packaged and prepared for distribution. Factories often use sustainable practices in packaging to minimize environmental impact.

Advantages of HDPE Corrugated Pipes

The benefits of using HDPE corrugated pipes in various applications are numerous

hdpe corrugated pipe factory

- Durability HDPE is known for its resilience. Pipes can withstand heavy loads, making them ideal for use in road construction and other intense environments.

- Flexibility The corrugated design allows for easy installation, even in tight or irregular spaces. This flexibility reduces the need for joint fittings, which can be points of failure in traditional piping systems.

- Cost-effectiveness HDPE pipes are often more affordable than traditional materials like concrete or metal. Their lightweight nature reduces transportation costs, and the ease of installation can save on labor expenses.

- Environmental Sustainability HDPE is a recyclable material, and many factories incorporate recycled HDPE into their production process. Furthermore, the longevity and efficiency of these pipes contribute to sustainable infrastructure development.

Applications in Infrastructure

HDPE corrugated pipes find applications in various sectors, including

- Stormwater Management They are extensively used in stormwater drainage systems to control runoff and minimize flooding.

- Wastewater Treatment Their resistance to corrosion and chemicals makes them suitable for sewer lines and wastewater management systems.

- Utility Conduits Many utilities use HDPE pipes for electrical and telecommunications conduits due to their ease of installation and protective properties.

- Agricultural Uses Farmers utilize HDPE corrugated pipes for irrigation systems, helping to conserve water and optimize resource management.

Conclusion

With the construction and infrastructure sectors evolving rapidly, HDPE corrugated pipes offer a forward-thinking solution to the challenges of modern engineering. The wonders of manufacturing processes and innovations within HDPE corrugated pipe factories not only enhance durability and performance but also promote sustainability. As cities and rural areas alike continue to grow, HDPE corrugated pipes will undoubtedly play an integral role in building a more resilient and efficient future for infrastructure development.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025