Dec . 11, 2024 10:24 Back to list

HDPE Corrugated Pipe Manufacturing Process and Best Practices for Quality Production

The Significance of HDPE Corrugated Pipe Factories in Modern Infrastructure

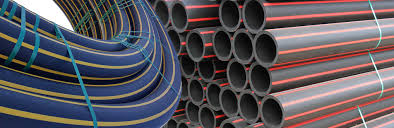

High-Density Polyethylene (HDPE) corrugated pipes have become an integral part of modern infrastructure, providing durable and versatile solutions for various drainage and utility applications. The rise of HDPE corrugated pipe factories has revolutionized the manufacturing process, allowing for more efficient production and meeting the growing demands of civil engineering projects worldwide.

Understanding HDPE Corrugated Pipes

HDPE is a thermoplastic polymer that is known for its high strength-to-density ratio. The corrugated structure of these pipes provides added strength and flexibility, making them ideal for a variety of applications, including stormwater management, sewage systems, and underground utilities. The characteristics of HDPE, such as its resistance to chemicals and corrosion, extend the lifespan of the pipes, making them a cost-effective choice in the long run.

The corrugated design also allows for easy handling and installation, as the pipes are lightweight compared to traditional materials like concrete or clay. This quality not only expedites installation but also reduces labor costs and equipment needs, making projects more economical. Furthermore, HDPE pipes can be produced in various diameters and lengths, catering to specific construction requirements.

The Role of HDPE Corrugated Pipe Factories

The establishment of specialized HDPE corrugated pipe factories has significantly transformed the production landscape. These factories are equipped with advanced machinery and technology that enable mass production while maintaining strict quality control measures. Raw materials are sourced from reputable suppliers, and the production processes often adhere to stringent industry standards and regulations, ensuring that the final product is reliable and safe for use.

1. Efficiency and Scalability Modern HDPE corrugated pipe factories utilize automated systems, allowing for higher efficiency and scalability in production. This technological advancement means that factories can quickly respond to fluctuating market demands, ensuring that contractors and construction companies have the materials they need, when they need them.

hdpe corrugated pipe factory

2. Environmental Considerations As the world becomes increasingly eco-conscious, HDPE corrugated pipe factories are shifting towards sustainable practices. Many factories are incorporating recycled materials into their production processes, reducing overall waste. Additionally, HDPE is fully recyclable, which helps in minimizing the environmental impact of construction projects.

3. Innovation in Design Factory production allows for innovation in pipe design and functionality. Engineers and manufacturers are constantly exploring new ways to enhance the performance of HDPE pipes, such as integrating smart technology for monitoring water flow and detecting leaks. This focus on innovation positions HDPE corrugated pipes as a forward-thinking choice for future infrastructure projects.

Market Demand and Growth

The demand for HDPE corrugated pipes has been steadily increasing due to several factors. Urbanization and the expansion of infrastructure projects worldwide necessitate efficient drainage and sewage systems. Additionally, the growing awareness of environmental issues has led many municipalities and construction firms to choose HDPE pipes over traditional materials, thanks to their durability and reduced carbon footprint.

As cities continue to expand, the need for reliable and sustainable infrastructure will only grow. HDPE corrugated pipe factories are poised to play a pivotal role in meeting this demand, driving growth in both the manufacturing sector and the construction industry.

Conclusion

In conclusion, HDPE corrugated pipe factories represent a significant advancement in infrastructure technology. By providing innovative, efficient, and sustainable solutions, these factories not only meet the current market demands but also lay the groundwork for future developments in civil engineering. As we continue to navigate the challenges of urban expansion and environmental sustainability, the importance of HDPE pipes will only become more pronounced, making it crucial for industries and governments to invest in these advanced manufacturing capabilities. In a rapidly changing world, the role of HDPE corrugated pipe factories will be fundamental in shaping resilient and sustainable infrastructures for generations to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025