Oct . 07, 2024 08:27 Back to list

hdpe conduit fittings manufacturer

Understanding HDPE Conduit Fittings A Comprehensive Look at Manufacturers and Their Products

High-Density Polyethylene (HDPE) conduit fittings have become a cornerstone in the construction and utility industries due to their remarkable strength, flexibility, and resistance to corrosion. As cities and infrastructure evolve, the demand for dependable and efficient conduit systems is growing. This article delves into the world of HDPE conduit fittings manufacturers, emphasizing their significance, the advantages of HDPE materials, and the factors to consider when choosing a manufacturer.

The Importance of HDPE Conduit Fittings

HDPE conduit fittings are essential components in underground electrical and communication systems. They protect cables from environmental factors and physical stress, ensuring long-lasting performance and reliability. The demand for these fittings has risen significantly, mainly due to the expanding telecommunications and electrical sectors, which continuously require robust solutions for cable management.

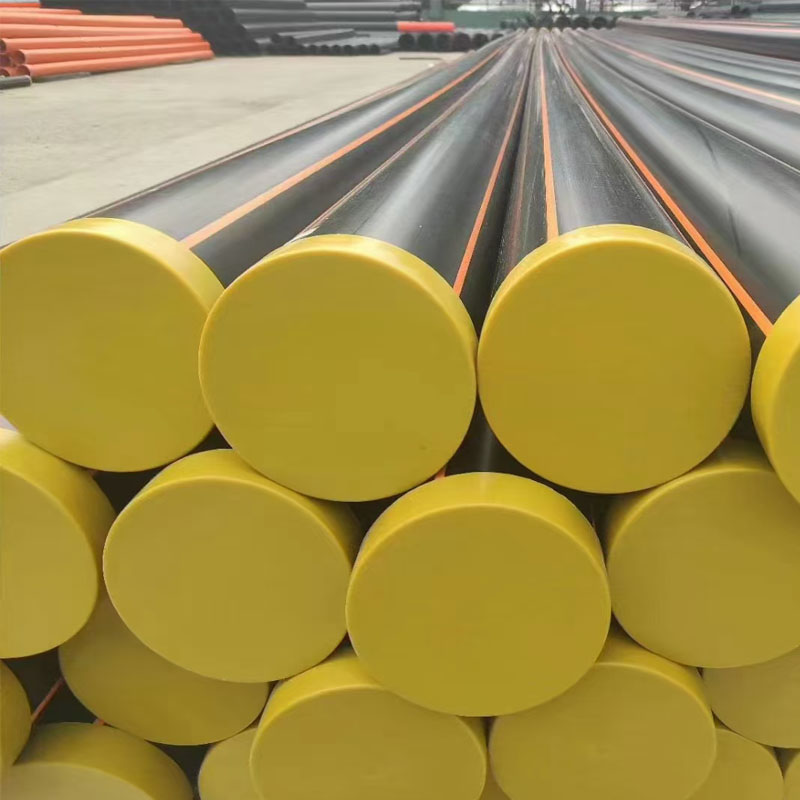

Manufacturers of HDPE conduit fittings play a vital role in this ecosystem by providing different types of fittings, including elbows, tees, reducers, and end caps. These products are integral to forming a complete conduit system that directs, protects, and organizes cables effectively.

Advantages of HDPE Material

One of the primary reasons for the growing popularity of HDPE in conduit systems is its unique characteristics. These benefits include

1. Durability HDPE is known for its high resistance to impact and crushing forces, making it ideal for harsh environments. Its longevity reduces the frequency of repairs and replacements, ultimately saving costs.

2. Corrosion Resistance Unlike metal fittings, HDPE does not corrode when exposed to moisture or chemicals. This feature is particularly valuable in environments subject to soil chemicals or salts, which can degrade metal products over time.

3. Flexibility HDPE can bend without breaking, allowing for easier installation in various terrains and reducing the need for additional fittings. This adaptability is a significant advantage when navigating tight spaces or complex layouts.

4. Lightweight The lightweight nature of HDPE simplifies transportation and handling during installation. This advantage can lead to reduced labor costs and quicker project timelines.

hdpe conduit fittings manufacturer

5. Environmental Impact HDPE is recyclable, making it an eco-friendly option for conduit systems. Many manufacturers adhere to sustainable practices, further contributing to environmental conservation.

Choosing the Right Manufacturer

With numerous manufacturers producing HDPE conduit fittings, selecting the right one requires careful consideration. Here are several factors to keep in mind

1. Quality Standards Look for manufacturers that comply with industry standards and certifications. This compliance ensures that the products meet necessary performance and safety requirements.

2. Product Range A reputable manufacturer should offer a wide range of fittings to cater to various project needs. This diversity allows for better customization and integration into existing systems.

3. Customer Support Good customer service is crucial when working with any manufacturer. Providers should offer technical support, product information, and assistance to ensure a seamless purchasing experience.

4. Pricing While cost should not be the only determining factor, it remains an essential aspect of any procurement process. Compare prices but also weigh them against the quality and service provided.

5. Reputation and Reviews Research the manufacturer’s reputation within the industry. Customer testimonials and reviews can provide valuable insights into the manufacturer’s reliability and product effectiveness.

6. Sustainability Practices As the focus on environmental responsibility increases, consider manufacturers that incorporate sustainable practices into their production processes.

Conclusion

HDPE conduit fittings are pivotal in maintaining efficient and reliable electrical and communication networks. With the rising demand for these fittings, choosing the right manufacturer is critical for ensuring project success. By focusing on quality, flexibility, and customer support, stakeholders in the construction and utility sectors can ensure that they select the best products for their needs. The ongoing innovations in HDPE technology and increasing supplier competition bode well for the future of conduit systems, promising enhanced performance and sustainability for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025