Dec . 16, 2024 02:43 Back to list

HDPE Conduit Fittings Manufacturing Overview and Industry Insights

The Significance of HDPE Conduit Fittings in Electrical Infrastructure

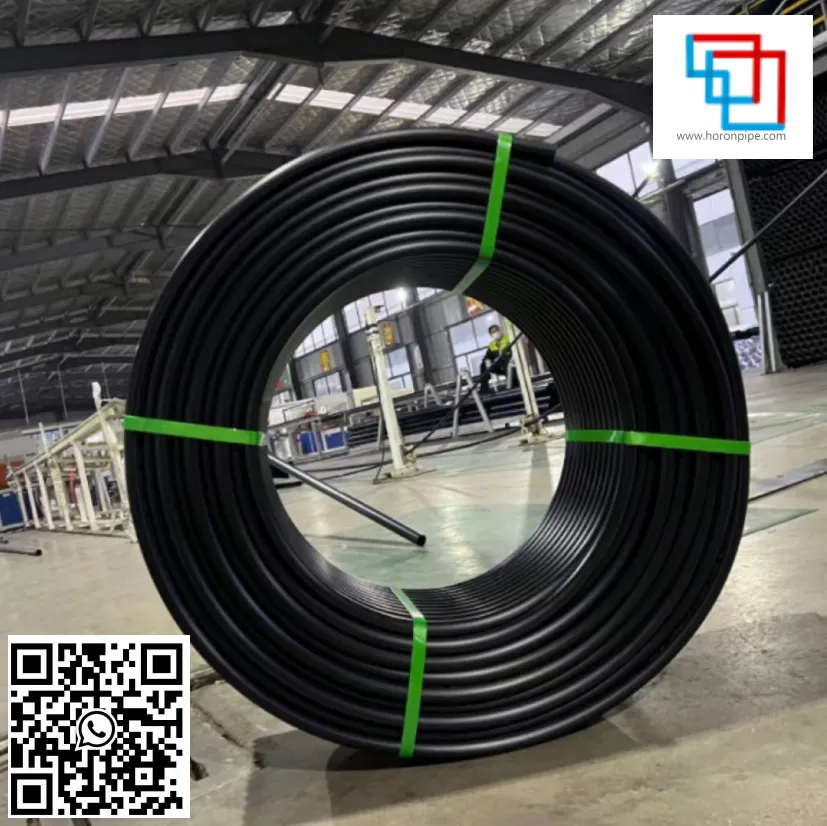

High-Density Polyethylene (HDPE) conduit fittings have emerged as an essential component in modern electrical infrastructure. As the demand for reliable, durable, and effective electrical solutions grows, the role of HDPE fittings becomes increasingly important. This article delves into the various aspects of HDPE conduit fittings, their manufacturing processes, advantages, applications, and the significance of factories producing them.

Understanding HDPE Conduit Fittings

HDPE is a thermoplastic polymer known for its high strength-to-density ratio. It is widely used in various industries, including plumbing, telecom, and electrical sectors, due to its superior properties compared to traditional materials. HDPE conduit fittings are integral for protecting electrical wires and cables from environmental hazards. These fittings help achieve secure connections, providing robustness in installation practices.

Manufacturing Process of HDPE Conduit Fittings

The production of HDPE conduit fittings involves several sophisticated processes that ensure quality and performance. Factories manufacturing these fittings typically follow strict quality control measures. The primary stages include

1. Material Selection High-quality HDPE resin is chosen based on the desired application. The resin must meet specific industry standards to guarantee durability and performance. 2. Extrusion The selected HDPE resin is fed into an extruder where it is heated and formed into the desired shape. This process allows for uniform wall thickness, a crucial factor in ensuring the strength of the fittings.

3. Molding After extrusion, the material undergoes a molding process where it is shaped into various fittings such as elbows, tees, and couplings. This step involves cooling the molded products to solidify them.

4. Quality Inspection Every batch is rigorously inspected for defects, ensuring each fitting meets industry standards. This step is vital to maintain reliability and safety in electrical installations.

5. Packaging and Distribution After inspection, the fittings are packaged for distribution to various suppliers and end-users, ready to be used in numerous projects.

Advantages of HDPE Conduit Fittings

hdpe conduit fittings factories

1. Durability HDPE fittings are resistant to corrosion and chemical degradation, making them ideal for outdoor and underground installations.

2. Lightweight Compared to traditional materials like metal, HDPE is much lighter, making transportation and handling easier.

3. Flexibility HDPE conduits can be easily bent and shaped, allowing for versatile installation in complex environments.

4. Cost-Effectiveness The long lifespan of HDPE fittings reduces replacement costs, making them an economical choice for electrical installations.

5. Environmental Resistance HDPE is resistant to UV rays and can withstand extreme temperatures, which is essential for maintaining performance in diverse climates.

Applications of HDPE Conduit Fittings

The versatility of HDPE fittings allows them to be used in a wide range of applications, such as

- Telecommunications Used for protecting and routing fiber optic cables. - Power Distribution Ideal for underground and overhead electrical installations. - Industrial Applications Used in factories for safe wiring systems. - Renewable Energy Suitable for installations related to solar and wind energy systems.

Conclusion

The production of HDPE conduit fittings is a pivotal aspect of ensuring a modern, reliable electrical infrastructure. Factories dedicated to manufacturing these components not only adhere to high-quality standards but also contribute to advancements in sustainable electrical solutions. As the demand for efficient and resilient electrical systems continues to rise, the role of HDPE fittings will undoubtedly become more significant, positioning themselves as crucial elements in the future of electrical infrastructure development. With ongoing innovations and improvements, HDPE conduit fittings help pave the way for a safer, more efficient electrical landscape.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025