Aug . 18, 2024 07:23 Back to list

HDPE to PVC Coupling Supplier for Reliable Plumbing Connections and Solutions

Understanding HDPE to PVC Coupling Manufacturers

In the realm of plumbing and piping solutions, achieving seamless connections between different types of materials is essential. One common coupling encountered in this field is the HDPE (High-Density Polyethylene) to PVC (Polyvinyl Chloride) coupling. These couplings are vital in various applications, including construction, irrigation systems, and wastewater management. As industries continue to grow, the demand for reliable, efficient coupling solutions has led to the rise of numerous manufacturers specializing in HDPE to PVC couplings.

The Importance of HDPE and PVC

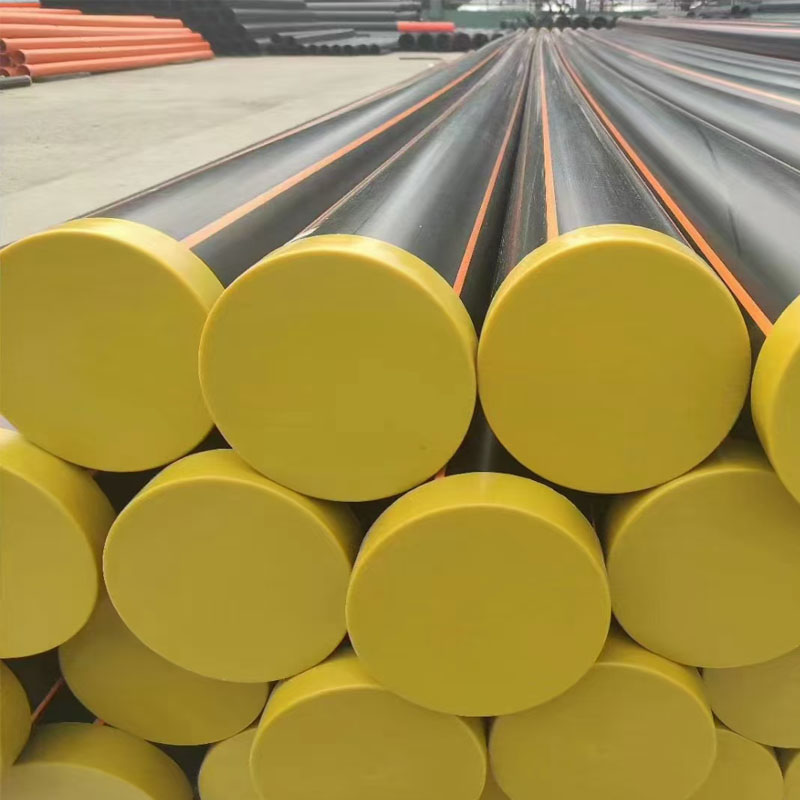

High-Density Polyethylene (HDPE) is renowned for its strength, durability, and resistance to corrosion and chemicals. It is widely used in piping systems for water distribution, gas pipelines, and numerous other applications. PVC, on the other hand, is known for its affordability and versatility. It is commonly found in plumbing systems, drainage, and sewerage. Each material has its strengths, but the challenge arises when these two materials need to be connected.

Understanding the properties of both materials is critical. While HDPE is more flexible and resistant to impact, PVC is more rigid and provides a better seal when glued. The coupling that connects these two must take into consideration these characteristics and ensure that the transition between materials is smooth and durable.

Role of Manufacturers

Manufacturers of HDPE to PVC couplings play a pivotal role in ensuring that these connections are reliable and efficient. These companies cater to both the residential and commercial markets, providing solutions that meet various regulatory standards and industry requirements. The coupling must not only connect two different materials but also withstand varying pressures and environmental conditions, thereby ensuring the longevity of the piping systems.

The process of manufacturing these couplings often involves advanced technology, including injection molding and extrusion processes. A skilled manufacturer will utilize high-quality raw materials and adhere to strict quality control measures to produce durable couplings that meet international standards. Moreover, most reputable manufacturers provide a range of sizes and designs, ensuring compatibility with various piping systems.

Key Considerations When Choosing a Manufacturer

hdpe to pvc coupling manufacturer

When selecting an HDPE to PVC coupling manufacturer, several factors should be considered

1. Quality Certifications Look for manufacturers that adhere to industry standards and possess relevant quality certifications. This can range from ISO certifications to specific certifications pertinent to plumbing and construction.

2. Experience and Reputation An established manufacturer with a proven track record is often a reliable choice. Research their history and reputation within the industry to understand their level of reliability.

3. Product Range A diverse range of products can indicate a manufacturer's capability and expertise. Ensure they offer couplings that meet your specific needs regarding size and function.

4. Customer Support Excellent customer service is crucial. Manufacturers should provide technical support and assistance regarding installation and application, helping customers make informed decisions.

5. Pricing and Value While cost is important, it should not be the sole factor. Evaluate the overall value, including the quality of the couplings and the manufacturer’s reputation, when making a decision.

Conclusion

In conclusion, HDPE to PVC couplings are essential components in modern plumbing and piping systems. As the demand for these products grows, manufacturers play a critical role in providing high-quality, reliable solutions. Whether for residential or commercial use, the right coupling can significantly impact the efficiency and durability of a piping system. By choosing the right manufacturer, you can ensure that your connections between HDPE and PVC are seamless, compliant, and built to last.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025