Sep . 03, 2024 21:51 Back to list

hdpe sewer pipe manufacturer

The Rise of HDPE Sewer Pipes An Industry Overview

High-Density Polyethylene (HDPE) has emerged as one of the leading materials for sewer pipe manufacturing in recent years. With its superior properties and growing demand for sustainable solutions, HDPE sewer pipes are revolutionizing the plumbing and drainage industries. This article explores the advantages, manufacturing processes, and applications of HDPE sewer pipes, as well as the key manufacturers in the market.

Advantages of HDPE Sewer Pipes

HDPE sewer pipes are renowned for their flexibility and durability. Unlike traditional materials such as concrete and PVC, HDPE is resistant to corrosion and chemical degradation. This quality makes it an excellent choice for various sewage and wastewater applications where exposure to harsh chemicals is common. Additionally, HDPE pipes have a smooth interior surface that minimizes friction and promotes efficient flow, reducing the risk of blockages.

Another significant advantage of HDPE pipes is their lightweight nature. This feature facilitates easier transportation and installation, ultimately lowering labor costs. Moreover, HDPE’s flexibility allows it to withstand ground movement and shifting, making it a reliable option for fluctuating soil conditions. The longevity of HDPE sewer pipes, often exceeding 50 years with proper installation, also contributes to their cost-effectiveness, providing long-term savings for municipalities and property developers.

Manufacturing Process

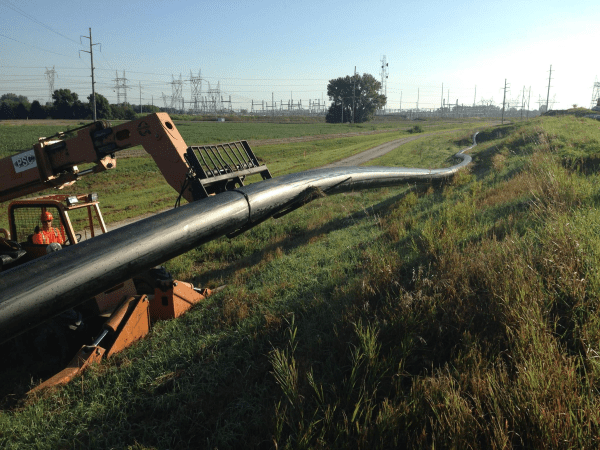

The manufacturing of HDPE sewer pipes involves several critical steps, starting with polymerization, where ethylene gas is transformed into high-density polyethylene resin. This resin is then granulated and extruded through a die to form long pipes. The pipes are subsequently cooled and cut to specified lengths. Manufacturers often employ advanced techniques such as co-extrusion to create multi-layered pipes that enhance performance and durability.

hdpe sewer pipe manufacturer

Quality control is paramount in the production process. Reputable manufacturers conduct rigorous testing to ensure compliance with international standards. This includes assessments of tensile strength, impact resistance, and chemical resistance. The use of recycled HDPE materials is also a growing trend, contributing to environmental sustainability without compromising the quality of the final product.

Applications of HDPE Sewer Pipes

HDPE sewer pipes are versatile and can be used in various applications, including municipal sewage systems, industrial discharges, and agricultural drainage. Their resistance to abrasion makes them particularly suitable for transporting wastewater and stormwater, where solid particles may cause wear over time. Additionally, HDPE’s fusion welding capabilities allow for seamless connections, further enhancing the integrity of the system.

Leading Manufacturers

The market for HDPE sewer pipes is competitive, with several key manufacturers leading the way. Companies such as Advanced Drainage Systems, Tigris Plastics, and Poly Pipe are renowned for their innovative solutions and commitment to quality. By implementing cutting-edge technologies and sustainable practices, these manufacturers are not only meeting current demands but also setting the stage for future advancements in sewer pipe technology.

Conclusion

As the construction and infrastructure sectors increasingly recognize the benefits of environmentally friendly materials, the demand for HDPE sewer pipes is expected to grow. With their unmatched durability, flexibility, and cost-effectiveness, HDPE pipes are set to become the preferred choice for sewer systems worldwide. As manufacturing methods continue to advance and new applications are explored, HDPE will likely play a critical role in shaping the future of sewerage infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025