Sep . 07, 2024 10:45 Back to list

HDPE Pipe Sizes and Dimensions - Comprehensive Guide

Understanding HDPE Pipe Sizes and Dimensions

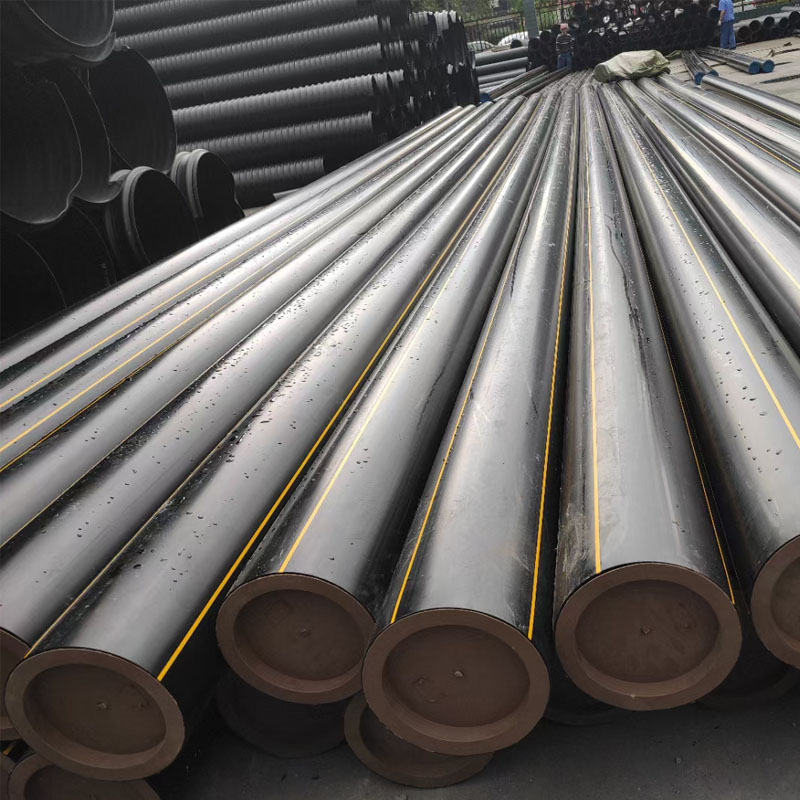

High-Density Polyethylene (HDPE) pipes are widely recognized for their durability, flexibility, and cost-effectiveness, making them a popular choice in various applications ranging from water supply to drainage systems. This synthetic polymer offers a robust solution for transporting fluids and is particularly valued in industries like agriculture, construction, and municipal applications. However, selecting the right HDPE pipe involves understanding its sizes and dimensions, which can significantly affect the efficiency of any project.

Understanding HDPE Pipe Sizes and Dimensions

The dimensions of HDPE pipes are also designated by the pipe's Standard Dimension Ratio (SDR), which refers to the pipe’s diameter divided by its wall thickness. A lower SDR signifies a thicker wall, which generally provides greater strength and pressure tolerance. For instance, SDR 11 pipes are commonly used in high-pressure applications, while SDR 17 pipes may suffice for lower pressures. Understanding the SDR is crucial when considering the operational pressures and potential suction forces that the pipe will encounter in the system.

hdpe pipe sizes and dimensions factory

Another important measurement to consider is the pipe's length. Generally, HDPE pipes are sold in standard lengths of 6 meters (20 feet) or 12 meters (40 feet), although custom lengths can be produced based on specific project requirements. The flexibility of HDPE allows for longer lengths, reducing the number of joints and potential leak points, which is an essential factor in improving the overall integrity of plumbing systems.

In addition to the standard sizes, HDPE pipes come with various fittings and accessories to accommodate complex installations. These can include elbows, tees, and transitions, designed to create a seamless connection between different pipe sizes or materials. It’s imperative to ensure compatibility between the pipes and fittings to maintain system efficiency and longevity.

When selecting HDPE pipes for a project, it’s also vital to consider the transport conditions and environmental factors to which the pipes will be exposed. Factors like temperature fluctuations, soil conditions, and potential chemical exposure should guide the selection of the appropriate grade and dimension of the pipe.

In conclusion, a thorough understanding of HDPE pipe sizes and dimensions is essential for engineers, contractors, and project managers involved in fluid transport systems. By selecting the right diameter, wall thickness, and accessories, professionals can ensure reliable performance and longevity for their piping needs. As the demand for efficient and sustainable infrastructure grows, HDPE pipe continues to be a prime choice, blending functionality with economic viability.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025