Aug . 21, 2024 06:50 Back to list

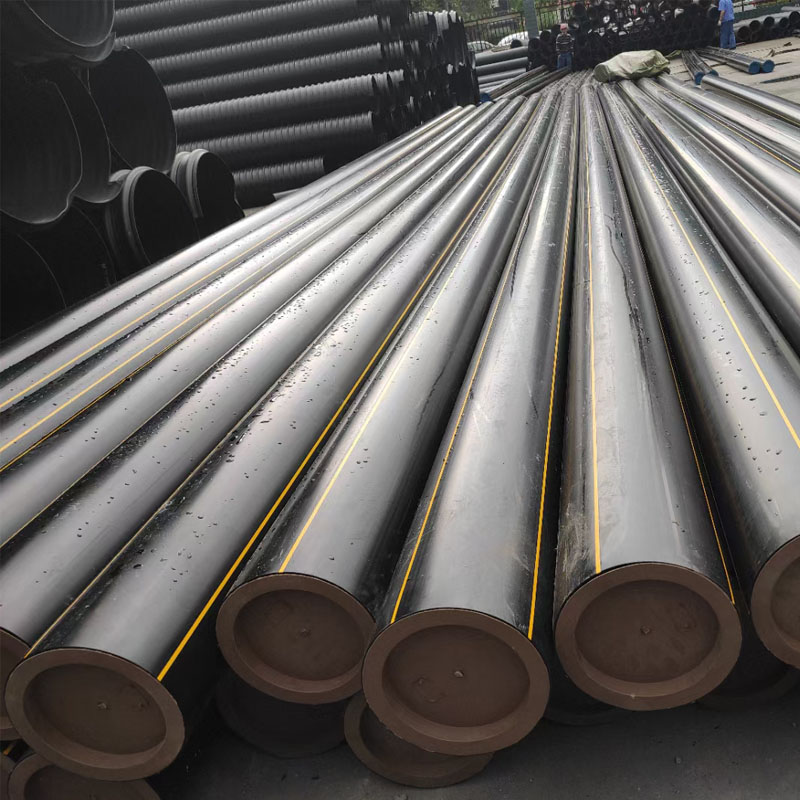

HDPE Pipe Size Specifications and Dimensions for Manufacturing Applications

Understanding HDPE Pipe Sizes and Dimensions

High-Density Polyethylene (HDPE) pipes have gained immense popularity in various industries due to their durability, flexibility, and resistance to corrosion and chemicals. These pipes are widely used for water supply, sewer systems, irrigation, and various industrial applications. Understanding HDPE pipe sizes and dimensions is crucial for engineers, contractors, and suppliers to ensure the efficient and effective design of plumbing systems.

What is HDPE?

HDPE, or High-Density Polyethylene, is a thermoplastic polymer made from petroleum. It is known for its high strength-to-density ratio, making it one of the most versatile materials in the piping industry. It is lightweight yet exceptionally strong, making it ideal for a wide range of applications. Moreover, HDPE pipes are resistant to impact, and rust, and do not corrode, which significantly reduces the maintenance costs associated with other pipe materials.

Standard Sizes of HDPE Pipes

HDPE pipes are available in various sizes, and the choice of dimensions often depends on the application and the expected flow rates. The International Organization for Standardization (ISO) has set standards for HDPE pipe sizes, which are typically denoted by their nominal diameter (DN) and the pressure rating (PN). Common diameter sizes range from 20 mm (approximately 0.75 inches) to over 1,200 mm (approximately 48 inches).

Generally, HDPE pipes are available in several standard sizes, categorized into different pressure ratings

- Low-Pressure Series Commonly used for irrigation and drainage, these typically range from 20 mm to 300 mm in diameter. - Medium-Pressure Series These range from 90 mm to 600 mm, suitable for water supply and industrial applications. - High-Pressure Series Essential for heavy-duty applications, these pipes measure from 250 mm to above 1,200 mm.

Dimensions and Wall Thickness

hdpe pipe sizes and dimensions factory

When selecting HDPE pipes, wall thickness becomes a critical factor, affecting the pipe's pressure rating and overall durability. The thickness is determined by the pipe's SDR (Standard Dimension Ratio), which is the ratio of the pipe's diameter to its wall thickness. For example, a pipe with a lower SDR value has a thicker wall and is suitable for higher pressure applications. Typical SDR values range from SDR 7.4 to SDR 41.

Benefits of Utilizing HDPE Pipes

1. Corrosion Resistance Unlike metal pipes, HDPE does not rust or corrode, ensuring a prolonged service life. 2. Flexibility and Durability Its flexibility makes it easy to install in various environments, and its durability minimizes breakage and leaks.

3. Low Thermal Conductivity HDPE pipes are excellent insulators, which helps to reduce energy costs in temperature-sensitive applications.

4. Environmentally Friendly HDPE is recyclable, which makes it a more sustainable choice compared to traditional materials.

5. Cost-Effectiveness Although the initial material cost may be higher, the reduced maintenance and long service life make HDPE pipes a cost-effective choice over time.

Conclusion

In conclusion, understanding HDPE pipe sizes and dimensions is vital for selecting the right type of piping for various applications. With their standardized sizes, flexibility, and resistance to environmental factors, HDPE pipes have become a favored choice in modern infrastructure projects. Whether in municipal water supply, agricultural irrigation, or industrial processes, the versatility of HDPE makes it an essential component in contemporary piping systems. As the demand for reliable and sustainable materials continues to rise, HDPE will remain at the forefront of piping technology.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025