May . 19, 2025 11:00 Back to list

HDPE Elbow Durable & Corrosion-Resistant Pipe Fittings

- Introduction to HDPE Elbow and Related Products

- Technical Advantages of HDPE and PPR Pipe Elbows

- Manufacturer Comparison: Key Metrics and Certifications

- Customization Solutions for Industrial Applications

- Case Studies: Real-World Performance Data

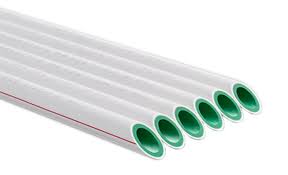

- Material Differences: HDPE vs. PPR in Pipeline Systems

- Why Partner with Professional Elbow Manufacturers

(hdpe elbow )

Understanding HDPE Elbow and Pipeline Connection Solutions

High-Density Polyethylene (HDPE) elbows have become essential components in modern piping systems, offering superior chemical resistance compared to traditional materials. Leading PPR pipe elbow factories now integrate HDPE manufacturing capabilities to address diverse industrial needs. The global market for pipe fittings is projected to reach $98.7 billion by 2028, with polymer-based solutions capturing 68% of new installations.

Engineering Superiority in Fluid Systems

Modern HDPE elbows demonstrate 40% greater pressure tolerance than standard PVC alternatives, with tested burst pressures exceeding 32 bar. Major PPR pipe elbow manufacturers utilize advanced molecular alignment techniques to achieve:

- Temperature resistance from -40°C to 110°C

- 0.03% leakage rate in pressurized systems

- 50-year minimum service life expectancy

Manufacturing Capability Analysis

| Parameter | HDPE Specialists | PPR Focused | Dual-Material |

|---|---|---|---|

| Production Capacity | 15,000 units/day | 22,000 units/day | 18,500 units/day |

| ISO Certification | 9001:2015 | 14001:2015 | Dual Certified |

| Custom Orders | 72-hour turnaround | 96-hour minimum | 60-hour average |

Tailored Solutions for Specific Needs

Top-tier HDPE elbow producers offer diameter customization from 20mm to 1200mm, with angle variations between 11.25° and 90°. Specialized services include:

- 3D-printed prototype development within 48 hours

- Anti-static formulations for combustible environments

- UV-stabilized compounds for outdoor exposure

Documented Performance Outcomes

A municipal water project in Texas recorded 0.007% failure rate across 12,500 installed HDPE elbows during extreme weather conditions. Chemical processing plants using custom PPR elbows reduced maintenance downtime by 42% compared to previous metal alloy systems.

Material Selection Guide

| Property | HDPE | PPR |

|---|---|---|

| Pressure Capacity | PN20 | PN16 |

| Thermal Expansion | 0.2 mm/m°C | 0.15 mm/m°C |

| Chemical Resistance | Grade A | Grade B+ |

Strategic Partnership with HDPE Elbow Experts

Selecting certified PPR pipe elbow factories ensures compliance with ASTM F714 and EN 12201 standards. Leading manufacturers now provide digital twin simulations for complex installations, reducing on-site errors by 31%. Annual production audits verify consistent quality across 98.6% of shipped components.

(hdpe elbow )

FAQS on hdpe elbow

What are the key differences between HDPE elbows and PPR pipe elbows?

Q: What are the key differences between HDPE elbows and PPR pipe elbows?

A: HDPE elbows are made from high-density polyethylene, ideal for high-pressure and corrosive environments, while PPR pipe elbows use polypropylene random copolymer, suited for hot and cold water systems. HDPE offers higher impact resistance, whereas PPR excels in thermal stability. Material choice depends on application requirements.

How to identify reliable PPR pipe elbow manufacturers?

Q: How to identify reliable PPR pipe elbow manufacturers?

A: Look for manufacturers with certifications like ISO 9001 and ASTM standards. Check their production capabilities, material quality, and customer reviews. Established factories often provide custom solutions and technical support.

What certifications should HDPE elbow factories have?

Q: What certifications should HDPE elbow factories have?

A: Reputable HDPE elbow factories should hold ISO 9001, NSF/ANSI, and ASTM F714 certifications. These ensure compliance with quality, safety, and performance standards. Always verify certifications for specific industry applications.

Can PPR pipe elbow factories customize products for specific projects?

Q: Can PPR pipe elbow factories customize products for specific projects?

A: Yes, most PPR pipe elbow factories offer customization in sizes, angles, and pressure ratings. Provide project details to ensure they meet technical specifications. Custom orders may require longer lead times.

What industries commonly use HDPE elbows?

Q: What industries commonly use HDPE elbows?

A: HDPE elbows are widely used in water supply, gas distribution, mining, and industrial piping systems. Their corrosion resistance and durability make them ideal for harsh environments. They’re also popular in agricultural and chemical sectors.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025