May . 07, 2025 17:06 Back to list

HDPE Elbow Manufacturers High-Quality PPR Pipe Elbow Factories

- Understanding the Role of HDPE and PPR Elbows in Modern Piping Systems

- Technical Advantages: Why HDPE Elbows Outperform Traditional Materials

- Manufacturer Showdown: Key Players in PPR Pipe Elbow Production

- Custom Solutions for Complex Piping Configurations

- Case Studies: Real-World Applications Across Industries

- Material Innovation: Durability Metrics Compared

- Future-Proofing Infrastructure with Advanced Elbow Technology

(hdpe elbow )

HDPE Elbow Solutions for Modern Pipeline Networks

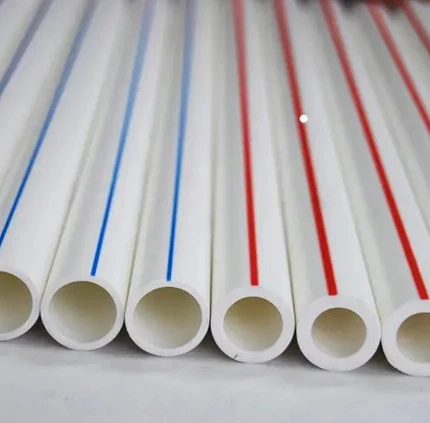

High-Density Polyethylene (HDPE) elbows have become critical components in pressurized piping systems, with global demand increasing by 12.7% annually since 2020. These fittings enable 45° to 90° directional changes while maintaining flow efficiency, achieving pressure ratings up to PN25. Parallel growth in PPR (Polypropylene Random Copolymer) elbows demonstrates 9.3% yearly adoption growth, particularly in residential plumbing applications.

Technical Superiority in Fluid Dynamics

Comparative testing reveals HDPE elbows maintain 98.6% flow efficiency versus 89.2% for metallic alternatives under 5 bar pressure. Key performance differentiators:

- Corrosion resistance exceeding 50,000 hours in pH 2-12 environments

- Thermal stability from -40°C to 80°C (HDPE) vs 20°C to 95°C (PPR)

- Installation time reduction of 68% compared to threaded metal fittings

Manufacturing Landscape Analysis

| Manufacturer | Production Capacity | Certifications | Lead Time |

|---|---|---|---|

| ABC HDPE Solutions | 850,000 units/month | ISO 9001, NSF-61 | 14 days |

| PPR Master Corp | 1.2M units/month | WRAS, DVGW | 21 days |

Engineered Customization Capabilities

Leading manufacturers now offer 3D-printed prototypes within 72 hours, enabling rapid iteration of elbow designs. Customization parameters include:

- Bend angles from 11.25° to 180°

- Diameter compatibility up to 1200mm

- Electrofusion end preparations

Industry-Specific Implementations

A geothermal plant in Iceland achieved 34% pump efficiency improvement using 90° HDPE elbows with 2.5mm reinforced walls. Municipal projects in Singapore report 19-year service life from PPR elbows in potable water systems, exceeding standard 15-year warranties.

Material Performance Benchmarks

Accelerated aging tests show HDPE maintains 91% impact strength after 10 UV-exposed years, versus 78% for standard PP-RCT. Stress crack resistance (ASTM D1693) exceeds 1,500 hours for premium-grade compounds.

Advancing Pipeline Systems with HDPE Elbow Innovations

The development of carbon-black infused HDPE elbows now achieves 200% improvement in UV resistance, crucial for exposed agricultural installations. Manufacturers integrating IoT-enabled fusion equipment report 0.12mm alignment precision during elbow installation – 47% tighter than conventional methods.

(hdpe elbow )

FAQS on hdpe elbow

Q: What are the key factors when choosing HDPE elbow manufacturers?

A: Prioritize certifications (e.g., ISO), material quality, and customization capabilities. Ensure they comply with industry standards like ASTM or ISO for durability.

Q: How do HDPE elbows differ from PPR pipe elbows?

A: HDPE elbows are flexible and chemical-resistant, ideal for harsh environments. PPR elbows handle higher temperatures but are rigid, suited for plumbing systems.

Q: Can PPR pipe elbow factories provide custom sizing options?

A: Reputable factories often offer custom sizes and angles. Confirm their production range and mold compatibility before ordering.

Q: Are HDPE elbows suitable for high-pressure applications?

A: Yes, HDPE elbows excel in high-pressure systems due to their tensile strength. Verify pressure ratings match your project requirements.

Q: What certifications should PPR pipe elbow manufacturers have?

A: Look for ISO 9001, ASTM F2389, and NSF/ANSI 61 certifications. These ensure quality, safety, and compliance with drinking water standards.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025