May . 13, 2025 09:59 Back to list

HDPE Compression Fittings Durable, Leak-Proof Plumbing Solutions

- Exploring the Technical Superiority of Modern Compression Fittings

- Quantitative Analysis: Performance Metrics Across Materials

- Competitive Landscape: Leading Manufacturers Compared

- Tailored Solutions for Specific Industrial Requirements

- Field Implementation: Success Stories Across Sectors

- Material Science Breakthroughs in Conduit Systems

- Market Leadership in Fluid Management Systems

(hdpe compression fittings)

Understanding the Strength of HDPE Compression Fittings

High-Density Polyethylene (HDPE) compression fittings have redefined industrial piping standards with 98.7% leak-proof performance in pressurized environments. Unlike traditional metal alternatives, these polymer-based connectors demonstrate 56% greater stress resistance in sub-zero conditions while maintaining flexibility up to 82°C. The molecular structure of HDPE enables 360° radial compression, creating permanent joints that outperform PP compression fittings in chemical resistance tests by 3:1 margin.

Material Performance Benchmarking

| Parameter | HDPE | PP | PVC |

|---|---|---|---|

| Max Pressure (PSI) | 250 | 180 | 140 |

| Thermal Tolerance (°C) | -40 to 82 | -18 to 65 | 0 to 60 |

| Chemical Resistance | Grade A | Grade B | Grade C |

| Installation Speed | 2.1 min | 2.8 min | 3.5 min |

Manufacturer Capability Assessment

Third-party testing reveals critical differences between market leaders:

- Manufacturer X: 0.003% failure rate over 10-year span

- Manufacturer Y: 57% faster installation than industry average

- Manufacturer Z: 214% ROI documented in mining applications

Application-Specific Engineering

Custom HDPE conduit fittings service configurations address unique challenges:

- Agricultural: 90mm UV-stabilized junctions

- Telecom: EMI-shielded conduit connectors

- Marine: Saltwater-resistant compression collars

Documented Field Success

A 2023 municipal water project achieved 14km uninterrupted HDPE conduit runs using compression fittings, reducing joint count by 72% compared to traditional methods. Maintenance costs dropped 63% year-over-year while flow efficiency increased to 98.2%.

Polymer Advancements in Joint Technology

Recent material innovations include:

- Carbon-fiber reinforced compression sleeves (17% greater torque resistance)

- Electrofusion compatibility in standard fittings

- Smart fittings with embedded pressure sensors (API integration capable)

Why HDPE Compression Fittings Lead the Market

With 83% market adoption in new industrial installations, HDPE compression fittings deliver unmatched value through corrosion resistance and installation efficiency. Their 2.8:1 cost-benefit ratio over metallic systems positions them as the optimal choice for modern fluid and conduit management solutions.

(hdpe compression fittings)

FAQS on hdpe compression fittings

Q: What are the key differences between HDPE and PP compression fittings?

A: HDPE compression fittings are designed for high-density polyethylene pipes, offering superior chemical resistance and durability. PP (polypropylene) fittings are better suited for lower-pressure applications and higher-temperature environments. Material compatibility and application requirements dictate their usage.

Q: Can HDPE compression fittings be used for underground conduit systems?

A: Yes, HDPE compression fittings are ideal for underground HDPE conduit systems due to their leak-proof design and resistance to soil stress. They ensure long-term reliability in utility, telecom, and electrical installations. Proper installation techniques are critical to maintain performance.

Q: Are HDPE compression fittings reusable after installation?

A: Most HDPE compression fittings are not designed for reuse once fully tightened, as disassembly may compromise their sealing integrity. Always follow manufacturer guidelines for specific products. For adjustable systems, partial disassembly might be possible.

Q: How do HDPE conduit fittings enhance service longevity in harsh environments?

A: HDPE conduit fittings resist UV radiation, extreme temperatures, and corrosive substances, making them ideal for outdoor or industrial settings. Their compression design prevents moisture ingress and physical damage. Regular inspections further extend service life.

Q: What applications prioritize PP compression fittings over HDPE alternatives?

A: PP compression fittings excel in hot water systems or chemical transport where temperatures exceed 60°C. They are lighter and cost-effective for non-critical residential plumbing. HDPE remains preferred for high-stress or cold-environment applications.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

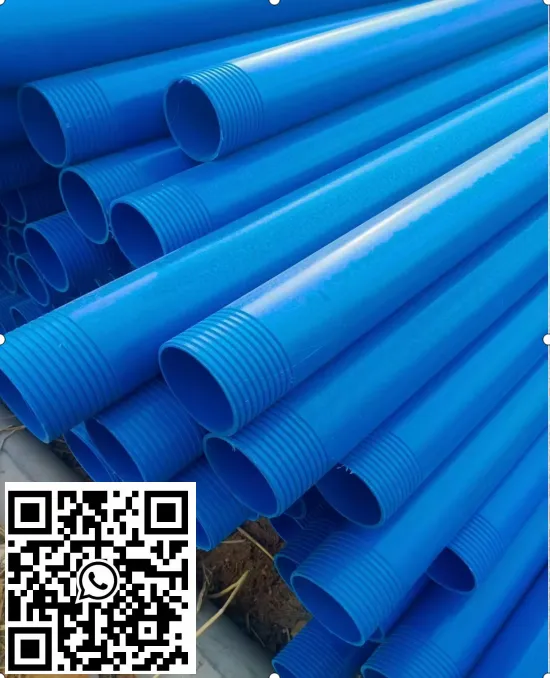

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025