Nov . 16, 2024 07:01 Back to list

double wall hdpe pipe factories

The Importance of Double Wall HDPE Pipe Factories

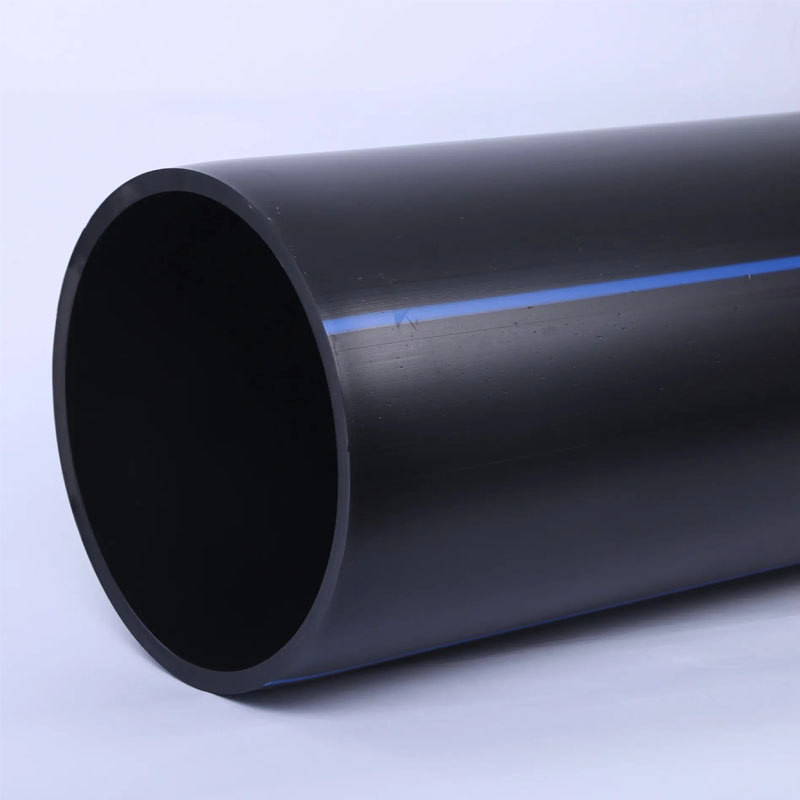

In the modern world, the demand for durable, efficient, and environmentally friendly piping systems is ever-increasing. Among the various options available, double wall high-density polyethylene (HDPE) pipes have emerged as a popular choice in many industries, including irrigation, sewage management, and industrial applications. The significance of double wall HDPE pipe factories cannot be overstated, as they play a crucial role in ensuring the availability and quality of these pipes.

Understanding Double Wall HDPE Pipes

Double wall HDPE pipes are engineered with two distinct layers. The outer layer provides strength and protection, while the inner layer ensures smooth fluid flow and resistance to corrosion. This design offers numerous advantages over traditional piping systems, such as enhanced durability, lightweight nature, and resistance to a wide range of chemicals. Additionally, double wall HDPE pipes are less prone to leakage, reducing the chances of environmental contamination.

The Role of Factories in Production

Double wall HDPE pipe factories are specialized manufacturing units that employ advanced technologies and quality control measures to produce these pipes. The production process typically involves the extrusion of HDPE resin, followed by the formation of the double wall structure. High-quality machinery and skilled labor are essential in ensuring that the pipes meet industry standards and specifications. These factories are equipped with state-of-the-art equipment that guarantees precision in wall thickness, diameter, and overall dimensional accuracy.

Factory processes are not just limited to the manufacturing of pipes; they also include rigorous testing for quality assurance. This might involve hydrostatic testing, impact resistance assessments, and environmental testing to ensure that the pipes can withstand real-world conditions. Factories often work closely with engineers and designers to develop pipes tailored to specific applications, further enhancing the versatility of double wall HDPE pipes.

Environmental Benefits

One of the primary reasons for the rising popularity of double wall HDPE pipes is their environmental friendliness. The production of these pipes involves less energy compared to traditional materials such as concrete or metal. Moreover, HDPE is recyclable, reducing waste and the carbon footprint associated with pipe manufacturing. Factories that prioritize sustainable practices not only contribute to environmental conservation but also position themselves favorably in the market.

double wall hdpe pipe factories

Market Demand and Industry Growth

The global market for double wall HDPE pipes has been witnessing substantial growth, driven by increasing urbanization, infrastructural development, and the need for efficient drainage systems. Industries across the globe are recognizing the benefits of using double wall HDPE pipes for various applications, leading to greater demand for their production. Factories that can scale their operations efficiently and maintain high standards of quality are finding themselves in a prime position to meet this rising demand.

Geographically, regions like North America, Europe, and Asia-Pacific are leading the consumption of HDPE pipes due to stringent environmental regulations and a push for sustainable construction practices. As a result, factories in these regions are adapting their production lines and methodologies to cater to the specific needs of different markets, highlighting the global interconnectedness of the industry.

Future of Double Wall HDPE Pipe Factories

As technology continues to evolve, double wall HDPE pipe factories are likely to benefit from innovations such as automation, IoT (Internet of Things), and advanced material science. These advancements can increase efficiency, reduce production costs, and improve the quality and performance of the pipes. Furthermore, the focus on smart infrastructure will likely drive demand for smart piping solutions, incorporating sensors and monitoring devices to enhance the functionality of piping systems.

Additionally, as awareness regarding climate change and environmental issues grows, factories that adopt sustainable practices and reduce waste will gain a competitive edge. The future of double wall HDPE pipe factories appears promising, with ample opportunities for growth and innovation in this vital sector.

Conclusion

In summary, double wall HDPE pipe factories are integral to meeting the needs of modern piping systems. Their commitment to quality, sustainability, and innovation positions them at the forefront of the industry. As the demand for efficient and eco-friendly solutions continues to climb, these factories will play a critical role in shaping the future of infrastructure development across the globe. By producing high-quality double wall HDPE pipes, they not only contribute to economic growth but also support the overarching goal of environmental protection.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025