Dec . 09, 2024 21:52 Back to list

DN500 Service Overview and Key Features for Optimal Performance Solutions

Understanding DN500 Service A Comprehensive Overview

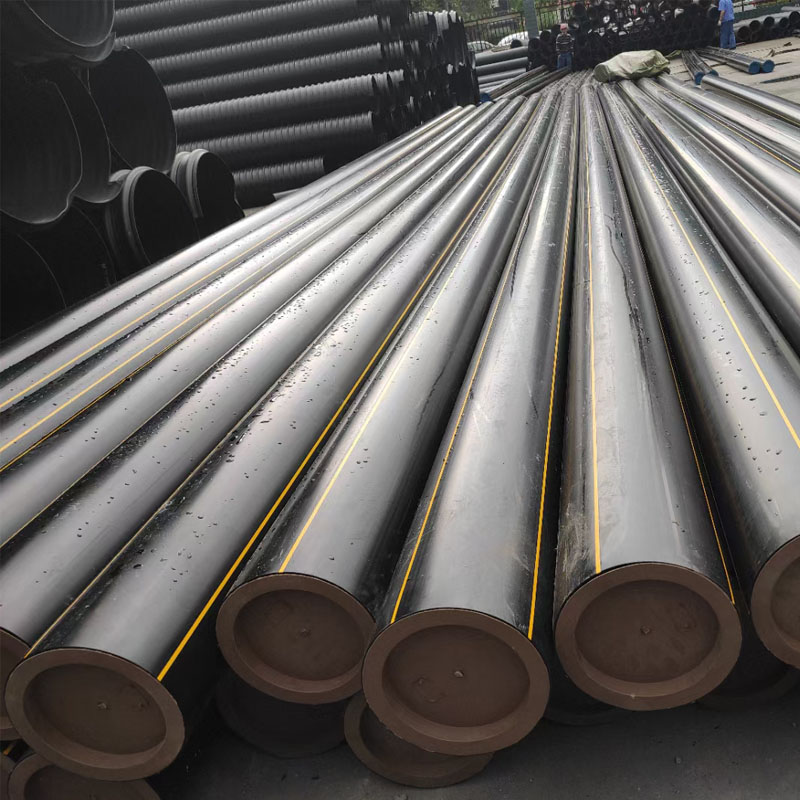

In today's fast-paced industrial landscape, the efficient management and operation of pipelines is vital for various sectors, including oil and gas, water supply, and chemical manufacturing. Among the many standards and specifications that govern pipeline systems, DN500 service stands out as a significant category. The term DN500 refers to a nominal diameter of 500 millimeters (approximately 20 inches), which is a common size used in many pipeline applications.

What is DN500?

The DN in DN500 stands for Diamètre Nominal, a term derived from French that translates to nominal diameter. This designation specifies the diameter of the pipe, which plays a crucial role in determining the flow capacity, pressure handling, and physical characteristics of the pipeline system. The 500mm size indicates that this type of pipe can accommodate a substantial flow rate, making it suitable for significant industrial applications.

Applications of DN500 Service

1. Water Supply Systems DN500 pipes are widely used in municipal water supply systems. Their large diameter allows for the efficient transport of water to meet the needs of growing populations. By using DN500 pipes, municipalities can ensure a steady and ample supply of potable water, reducing the risk of shortages during peak demand times.

2. Oil and Gas Transportation In the oil and gas industry, DN500 is a standard size for transporting hydrocarbons from extraction points to refineries and distribution centers. The strength and durability of DN500 pipes help them withstand high pressures and corrosive environments, making them ideal for these applications.

3. Wastewater Management In wastewater treatment plants, DN500 pipes play a critical role in transporting sewage and other waste materials to treatment facilities. Their size enables them to handle large volumes of waste, promoting efficient and effective sewage management.

4. Chemical Manufacturing The chemical industry also relies on DN500 pipes for transporting various chemical substances. The materials used for these pipelines are typically resistant to corrosion, ensuring that they can safely transport hazardous materials without risk of leaks or contamination.

Key Considerations for DN500 Service

When considering DN500 service, several factors must be taken into account to ensure optimal performance and safety

dn500 service

1. Material Selection DN500 pipes are available in various materials, including carbon steel, stainless steel, and polyethylene. The choice of material depends on the application and the specific properties required, such as corrosion resistance, temperature tolerance, and pressure rating.

2. Installation and Maintenance Proper installation is crucial in ensuring the longevity and effectiveness of DN500 pipelines. Conducting thorough inspections and regular maintenance can prevent leaks and other failures that could lead to costly downtime or environmental issues.

3. Flow Dynamics Understanding the flow dynamics within a DN500 pipeline is essential for optimizing performance. Factors such as pressure loss, flow rate, and fluid characteristics must be thoroughly analyzed to ensure that the system operates efficiently.

4. Regulatory Compliance Adhering to local and international standards and regulations is critical when installing and operating DN500 pipelines. Compliance ensures that the system meets safety and environmental standards, reducing the risk of legal implications and costly fines.

Future Trends in DN500 Service

As industries evolve and environmental considerations become increasingly paramount, the future of DN500 service is likely to see several noteworthy trends

1. Sustainable Materials There is a growing emphasis on the use of sustainable and recyclable materials for pipeline construction. This shift is driven by the need for greener practices and reduced environmental impact.

2. Smart Technology Integration The integration of smart technologies, such as sensors and IoT (Internet of Things) devices, into pipeline systems can enhance monitoring and control. These technologies enable real-time data collection, which can facilitate predictive maintenance and improve operational efficiency.

3. Enhanced Safety Measures With the growing emphasis on safety, manufacturers and operators of DN500 pipelines are likely to adopt more rigorous safety protocols and advanced monitoring systems to mitigate risks associated with leaks and failures.

Conclusion

The DN500 service is an integral component of modern infrastructure across various industries. By understanding its applications, materials, and compliance requirements, stakeholders can harness the benefits of DN500 pipelines effectively. As technology and practices continue to evolve, the future of DN500 service promises enhanced efficiency and sustainability, paving the way for a more resilient and capable pipeline infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025