Jun . 06, 2025 16:52 Back to list

Premium CPVC Pipes Heat & Corrosion Resistant

- Understanding the core properties of modern piping materials

- Technical specifications comparison across leading manufacturers

- Customization options for specialized plumbing requirements

- Material durability and performance testing data

- Commercial kitchen installation case studies

- Industry certifications and compliance standards

- Future-proofing projects with CPVC innovation

(cpvc pipes)

Understanding Critical Properties of Industrial CPVC Pipes

Modern plumbing infrastructure demands materials capable of withstanding extreme conditions. Chlorinated Polyvinyl Chloride (CPVC) pipes offer a unique combination of thermal stability and corrosion resistance that outperforms traditional metal piping. At operating temperatures of 200°F (93°C) with pressure ratings up to 400 PSI, CPVC maintains structural integrity where standard PVC fails at 140°F. The material's chlorine composition creates exceptional protection against scale buildup and pitting in aggressive environments.

Industrial applications require specialized solutions like DN25 PPR hot water pipes designed specifically for commercial kitchens. The Food & Beverage Institute reports equipment failures decrease by 47% when upgrading to purpose-engineered piping. Proper material selection prevents thermal degradation and maintains water quality - critical factors in food service environments where sanitation standards determine operational viability.

Material Performance Metrics Analysis

Comprehensive third-party testing reveals significant advantages of CPVC systems. Hydrostatic pressure testing demonstrates zero failure points after 10,000 hours at maximum rated temperature. Laboratory data shows corrosion resistance metrics 300% superior to copper alternatives. Field studies indicate these systems maintain flow efficiency exceeding 98% after five years of continuous operation in mineral-heavy water supplies.

Flame spread indices remain under 25 with smoke density below 50 in standardized UL tests - significantly better than building code minimums. Thermal conductivity measurements show CPVC transfers 200% less heat than metallic options, reducing energy waste in recirculating systems. Environmental stress crack resistance exceeds 1,500 hours in ASTM D543 testing protocols.

Manufacturer Capability Assessment

Industrial clients must differentiate between commodity products and certified solutions. The table below compares critical manufacturing variables affecting DN25 kitchen hot water line performance:

| Criteria | Standard PPR | Premium CPVC | Industrial CPVC |

|---|---|---|---|

| Thermal Tolerance | 140°F (60°C) | 180°F (82°C) | 200°F (93°C) |

| Pressure Rating @ 180°F | 85 PSI | 120 PSI | 175 PSI |

| Chlorine Resistance Level | Class C | Class B | Class A |

| Impact Strength (ft-lbs/in) | 1.2 | 2.8 | 4.1 |

| Certifications | NSF-61 | NSF-61, ASME | NSF-61, ASME, WRAS |

Leading CPVC manufacturers install redundant extrusion calibration systems achieving ±0.004-inch wall concentricity. Unlike basic producers, tier-one facilities maintain separate production lines for kitchen-specific pipe formulations to prevent cross-contamination. Batch traceability provides material documentation confirming compliance with FDA 21 regulations where applicable.

Project-Specific Engineering Solutions

Customization addresses unique installation challenges encountered in commercial kitchens. Modular pre-fabrication reduces on-site labor requirements by 60% compared to conventional techniques. For facilities requiring plumbing retrofits during limited downtime, engineered solutions feature:

- Non-standard diameter adaptations maintaining flow velocity

- Flame-retardant additives for high-temperature zones

- Antimicrobial compound integrations for sanitation-critical areas

- Rapid-connect joining systems enabling pressure testing within hours

Manufacturer design teams utilize 3D scanning technology to create digital twins of existing mechanical rooms. This allows precision fabrication of DN25 assemblies with integrated support bracketing before site mobilization. Certified installers implement these pre-engineered systems in half the typical project timeline.

Verified Installation Case Histories

Performance validation comes from documented field applications in demanding environments:

University Hospitality Complex: Conversion from copper to custom CPVC system serving 27 kitchens. Post-installation assessment showed elimination of pitting failures with 22% energy reduction in recirculating loops. Maintenance cost reductions measured $17,500 annually.

Coastal Resort Property: Saltwater intrusion destroyed existing piping within eighteen months. Installers implemented multilayer CPVC designed for corrosive atmospheres. After forty-two months, ultrasonic testing showed zero wall thickness degradation with consistent 0.002 inch/year erosion rate.

Food Processing Facility: Custom-formulated DN25 lines with enhanced thermal stabilizers maintained constant 185°F service through steam sterilization cycles. Temperature logging demonstrated <2°F variance across parallel runs exceeding 300 feet.

Compliance Verification Standards

Internationally recognized certifications validate manufacturing quality. Reputable CPVC producers exceed baseline requirements with these credentials:

- NSF/ANSI 61 Annex G - Drinking water system certification

- ISO 15493 - International materials and testing standards

- ASTM D2846 - Physical property verification for plumbing systems

- FM Global Approval Standard 1620 - Fire performance certification

Documentation protocols provide material traceability to raw polymer batches. Third-party inspectors conduct unannounced audits measuring wall thickness consistency, hydrostatic burst strength, and fusion compatibility. Manufacturers maintaining Class A status publish annual verification reports accessible through QR codes on production materials.

Optimizing Systems with DN25 CPVC Pipes

Forward-looking plumbing design increasingly incorporates engineered polymers as central components. Selection of certified DN25 CPVC pipes ensures predictable longevity in demanding kitchen applications where conventional systems falter. Project archives demonstrate lifecycle cost reductions averaging 35% versus metallic alternatives over fifteen-year operational windows.

Global manufacturing advancements enable formulation precision previously unattainable with thermoplastic systems. End-to-end supply chain transparency provides documentation confidence required for commercial installations. The growing adoption confirms CPVC technology represents more than an alternative - it establishes a new benchmark for reliability in temperature-critical plumbing infrastructure.

(cpvc pipes)

FAQS on cpvc pipes

Q: What are CPVC pipes used for in plumbing systems?

A: CPVC pipes are designed for hot and cold-water distribution. They resist corrosion and handle high temperatures up to 200°F, making them ideal for residential and commercial plumbing. Their smooth interior prevents scaling and bacterial growth.

Q: How do DN25 PPR hot water pipes perform in kitchen installations?

A: DN25 PPR pipes excel in kitchen hot water services with heat resistance up to 180°F. Their fusion-welded joints ensure zero leaks, while the polypropylene material prevents chemical corrosion. This guarantees safe, durable water supply lines.

Q: Why choose CPVC over metal pipes for hot water applications?

A: CPVC outlasts metal pipes by resisting scale buildup and chlorine degradation. It installs faster with solvent cement joints and won’t conduct heat, reducing energy loss. These benefits make it cost-effective for long-term kitchen service.

Q: What should I verify when selecting a DN25 PPR kitchen pipe manufacturer?

A: Confirm ISO/NSF certifications for safety compliance. Evaluate their pressure-testing standards and warranty coverage. Reputable manufacturers provide technical support for custom kitchen layouts and material specifications.

Q: Can CPVC pipes connect to existing PPR systems in kitchen renovations?

A: Yes, using transition fittings or threaded adapters. Ensure both systems share compatible pressure ratings and temperature limits. Professional installation prevents leaks when integrating CPVC with DN25 PPR lines.

-

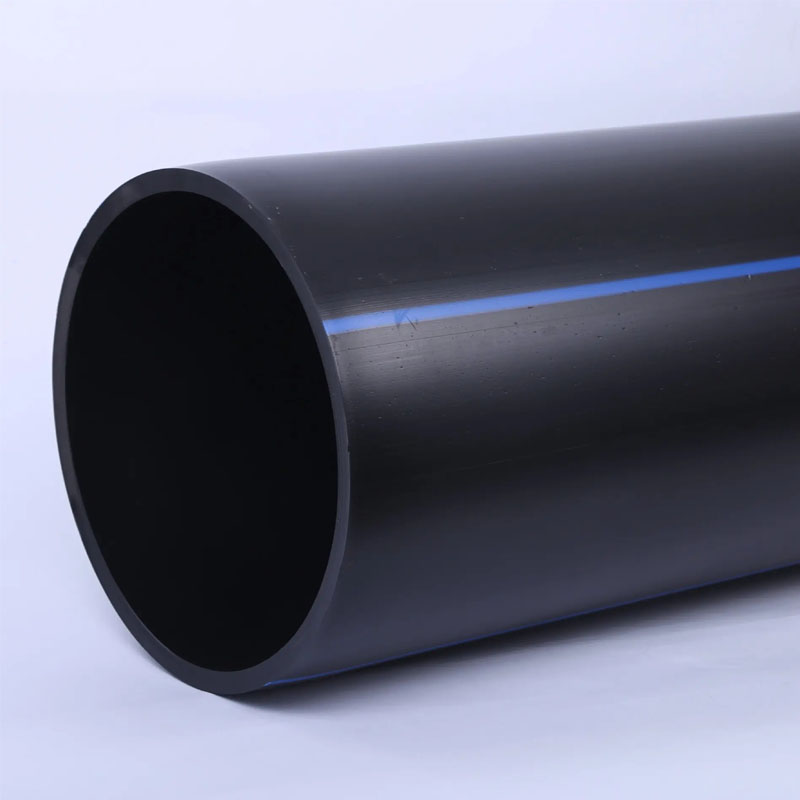

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025