Dec . 11, 2024 07:42 Back to list

coupler for hdpe pipe factories

The Importance of Couplers for HDPE Pipe Factories

High-Density Polyethylene (HDPE) pipes are widely used across various industries due to their durability, flexibility, and resistance to corrosion. These properties make HDPE pipes an ideal choice for water distribution, sewage systems, and even gas distribution. However, the efficacy of these pipes largely depends on the quality and functionality of the couplers used to connect them. As such, understanding the role of couplers in HDPE pipe factories is crucial for ensuring reliable and efficient pipeline systems.

Understanding HDPE Couplers

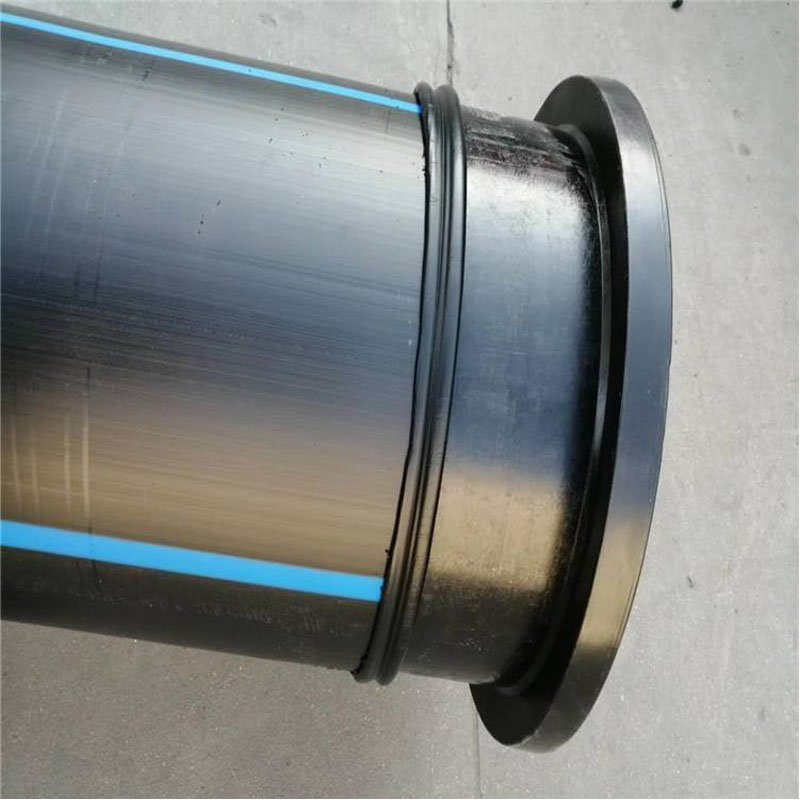

Couplers are essential fittings that connect two segments of HDPE pipe, allowing for the extension of the piping system needed in various applications. They serve several critical functions, including providing structural integrity, preventing leaks, and accommodating thermal expansion and contraction. Typically made from the same HDPE material, couplers must align perfectly with the pipes they connect to ensure maximum strength and durability.

The design of HDPE couplers can vary, incorporating features such as compression fittings, butt fusion joints, or electrofusion connections. Each type of coupling method offers distinct advantages. For instance, electrofusion couplers allow for a seamless joint that reduces the risk of leaks, making them particularly suitable for high-pressure applications.

Quality Control in Manufacturing

For HDPE pipe factories, the manufacturing process of couplers is equally critical as that of the pipes themselves. It is essential to maintain stringent quality control measures to ensure that the couplers can withstand the rigorous demands of the environments in which they will be installed. This includes testing for tolerance, resistance to pressure, and inspection for any defects or inconsistencies.

Utilizing advanced manufacturing technologies, such as automated machining and robotic assembly lines, can enhance the precision and efficiency of coupler production. Additionally, rigorous testing protocols, including hydrostatic testing and long-term environmental stress testing, help to ascertain the reliability of couplers produced.

coupler for hdpe pipe factories

The Role of Couplers in System Performance

Using high-quality couplers enhances the overall performance of HDPE piping systems. A strong, leak-proof connection prevents costly water loss and contamination, which is especially critical in applications involving potable water or sensitive materials. Additionally, a reliable coupling system significantly reduces the maintenance requirements of the pipeline, thus leading to lower operational costs over time.

Furthermore, in regions with significant temperature fluctuations, the flexibility of HDPE coupled with the heat-resilient nature of specialized couplers helps to absorb thermal expansion and contraction. This characteristic minimizes the risk of pipe failure due to external temperature changes, contributing to the longevity of the entire piping system.

Innovations in Coupler Design

Innovation is a continuous process in the HDPE pipe manufacturing industry. Couplers are undergoing enhancements in terms of design and materials to meet the evolving needs of industries. One emerging trend is the development of smart couplers with integrated sensors that can monitor pipeline conditions in real-time. These smart technologies can alert operators to potential leaks or pressure drops, enabling proactive maintenance and preventing catastrophic failures.

Moreover, research in sustainable materials has led to the creation of eco-friendly couplers that maintain functionality while minimizing the environmental impact. Such innovations align with global sustainability initiatives, promoting environmentally responsible practices in the manufacturing sector.

Conclusion

As the demand for HDPE pipes continues to grow across various sectors, the importance of high-quality couplers cannot be overstated. Couplers play a pivotal role in ensuring the integrity, efficiency, and longevity of piping systems. For HDPE pipe factories, focusing on the design, manufacturing quality, and innovative advancements in coupler technology is essential for staying competitive and meeting the needs of their clients. By prioritizing these factors, companies can not only enhance the reliability of their products but also contribute to a more sustainable future in pipeline infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025