Sep . 21, 2024 13:54 Back to list

corrugated hdpe pipe fittings manufacturer

The Importance of Quality in Corrugated HDPE Pipe Fittings Manufacturing

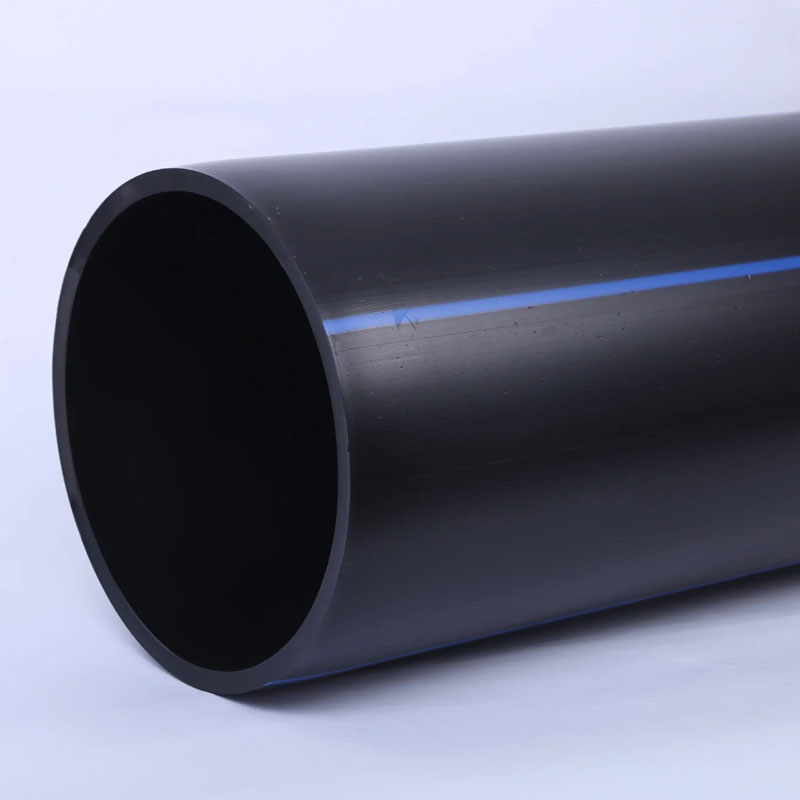

In the realm of modern construction and infrastructure, the efficient management of water, drainage, and sewage systems is critical. Among the various materials used for these applications, corrugated high-density polyethylene (HDPE) pipes stand out due to their flexibility, durability, and resistance to corrosion. However, the performance of these pipes largely depends on the quality of the fittings that connect them. In this article, we will explore the significance of high-quality corrugated HDPE pipe fittings and the role of manufacturers in ensuring their reliability.

The Importance of Quality in Corrugated HDPE Pipe Fittings Manufacturing

Quality manufacturers of corrugated HDPE pipe fittings adhere to strict industry standards and regulations. They utilize advanced manufacturing techniques and high-grade materials to produce fittings that meet or exceed the expected durability and performance criteria. For instance, the integration of advanced molding processes ensures that the fittings maintain a consistent wall thickness, which is crucial for withstanding external pressures and environmental factors such as soil movement and water table fluctuations.

corrugated hdpe pipe fittings manufacturer

Moreover, reputable manufacturers prioritize quality control throughout the production process. This includes rigorous testing for pressure resistance, structural integrity, and compatibility with various pipe types. Investing in such thorough testing not only ensures the dependability of the fittings but also protects the end-user's investment in their drainage or plumbing systems. A quality fitting can extend the lifespan of an HDPE pipe system and enhance its overall efficiency.

Additionally, sustainability is becoming increasingly important in pipe fitting manufacturing. Many manufacturers are now looking into recycling practices and innovative designs that reduce material waste while maintaining performance. This shift not only helps in conserving resources but also appeals to environmentally-conscious consumers looking for sustainable construction solutions.

In conclusion, the role of corrugated HDPE pipe fittings manufacturers is vital in the successful implementation of pipe systems across various sectors. By prioritizing quality and sustainability, these manufacturers ensure that their products enhance the performance, reliability, and longevity of HDPE piping systems. For anyone involved in the design and construction of water management systems, selecting high-quality fittings from reputable manufacturers should be a top priority, as it significantly impacts both the effectiveness and efficiency of the overall infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025