Aug . 18, 2024 15:15 Back to list

Corrugated Dual-Walled Pipes for Enhanced Durability and Performance in Various Applications

Corrugated Dual Wall Pipe An In-Depth Look

In the realm of civil engineering and construction, the choice of materials plays a crucial role in ensuring the durability, efficiency, and longevity of infrastructure projects. One innovative solution that has gained significant traction over the years is the corrugated dual wall pipe. This advanced piping system is increasingly being utilized for various applications, including drainage, stormwater management, and sewage systems.

What is Corrugated Dual Wall Pipe?

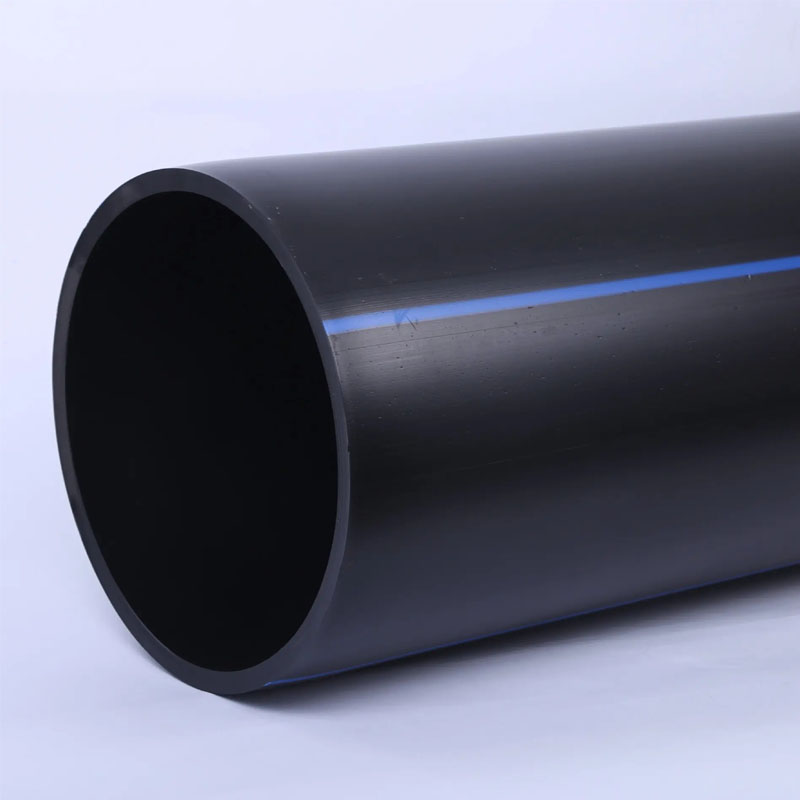

Corrugated dual wall pipe comprises two concentric layers an outer corrugated layer and a smooth inner wall. The outer wall is designed with a series of grooves or ridges, which significantly enhances its structural integrity while providing flexibility and increased resistance to soil movement. The smooth inner wall facilitates the efficient flow of liquids, reducing turbulence and minimizing the potential for blockages.

The combination of these two designs results in a pipe that is both sturdy and efficient. The corrugated outer layer can withstand considerable external pressures, making it ideal for underground installations where soil weight and environmental factors can pose challenges. Meanwhile, the smooth inner layer ensures that fluids can flow freely, maximizing the pipe’s capability to transport water and waste.

Advantages of Corrugated Dual Wall Pipe

1. Durability and Longevity One of the standout features of corrugated dual wall pipe is its impressive durability. Constructed from high-density polyethylene (HDPE) or polypropylene, these pipes are resistant to corrosion, chemicals, and UV rays. Their resistance to wear and tear ensures a longer lifespan, reducing the need for frequent replacements.

2. Lightweight and Easy to Handle Despite their strength, corrugated dual wall pipes are surprisingly lightweight compared to traditional materials like concrete or metal. This characteristic simplifies transportation and installation, allowing contractors to complete projects more efficiently.

corrugated dual wall pipe product

3. Cost-Effectiveness The long lifespan and reduced maintenance needs of corrugated dual wall pipes contribute to overall cost savings. Although the initial investment may be comparable or slightly higher than conventional pipes, the long-term benefits, including reduced repair costs and lower installation expenses, make it a cost-effective choice in the long run.

4. Environmental Impact Many manufacturers produce corrugated dual wall pipes using recycled materials, contributing to environmental sustainability. Additionally, their efficient design promotes better stormwater management, reducing the risk of flooding and erosion.

5. Versatility in Applications Corrugated dual wall pipes are suited for a variety of applications, from residential drainage systems to large-scale municipal sewage systems. Their adaptability allows for extensive use in different types of projects, making them a go-to option for engineers and contractors alike.

Installation and Maintenance

Installing corrugated dual wall pipes is generally straightforward, allowing for swift completion of projects. However, it is essential to adhere to proper installation guidelines to ensure optimal performance. This includes considerations for appropriate bedding materials, excavation depth, and backfilling techniques.

Maintenance of corrugated dual wall pipe systems is minimal due to their smooth interior surfaces that resist clogging. Regular inspections can help identify any potential issues early on, but overall, these systems require less upkeep compared to traditional piping solutions.

Conclusion

Overall, corrugated dual wall pipes represent a significant advancement in piping technology. Their combination of strength, flexibility, and efficiency positions them as an ideal solution for various water management applications. As construction practices continue to evolve, the adoption of innovative materials like corrugated dual wall pipe will undoubtedly play a pivotal role in shaping sustainable infrastructure for the future. With growing environmental consciousness and the need for durable solutions, these pipes are well-equipped to meet the demands of modern engineering challenges.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025