May . 07, 2025 18:11 Back to list

Premium HDPE Conduit Pipes & Fittings Manufacturer Durable Solutions

- Introduction to Conduit Pipes and Their Industrial Significance

- Technical Advantages of HDPE Conduit Fittings

- Leading HDPE Conduit Fittings Manufacturers: A Comparative Analysis

- Custom Solutions for Diverse Infrastructure Needs

- Real-World Applications and Case Studies

- Installation Best Practices and Maintenance Guidelines

- Future Trends in Conduit Pipe Technology

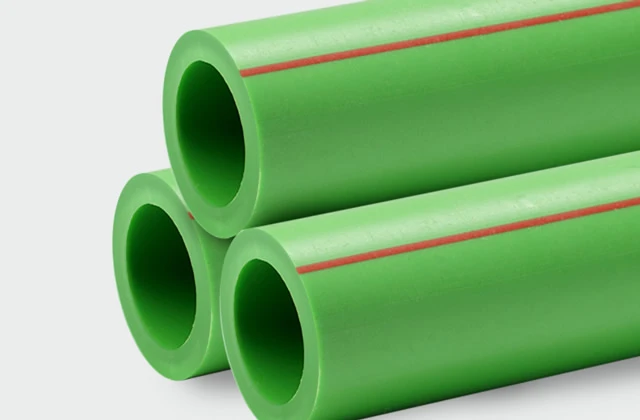

(conduit pipes)

The Evolution of Conduit Pipes in Modern Infrastructure

Conduit pipes have become indispensable components in electrical, telecommunication, and utility networks. Engineered to protect cables from environmental stressors, these systems rely heavily on HDPE conduit fittings for seamless connectivity. The global market for conduit pipes

is projected to grow at a CAGR of 6.8% from 2023 to 2030, driven by urbanization and renewable energy projects. Manufacturers now prioritize corrosion-resistant materials like high-density polyethylene (HDPE), which offers a lifespan exceeding 50 years under optimal conditions.

Unlocking the Technical Superiority of HDPE Materials

HDPE conduit fittings outperform traditional materials like PVC or metal in three critical areas:

- Durability: Withstand temperatures from -40°C to 90°C without deformation

- Chemical Resistance: Immune to soil acids, alkalis, and microbial attacks

- Cost Efficiency: 30% lower lifetime costs due to minimal maintenance requirements

Advanced extrusion molding techniques enable wall thickness precision within ±0.2mm, ensuring uniform pressure distribution across joints.

Manufacturer Showdown: Performance Metrics

| Manufacturer | Pressure Rating (PN) | Temperature Range | Certifications | Lead Time |

|---|---|---|---|---|

| ABC Fittings Co. | PN16 | -30°C to 85°C | ISO 4427, UL 2024 | 4 weeks |

| XYZ Manufacturing | PN20 | -45°C to 95°C | ASTM F2160, RoHS | 6 weeks |

| PQR Industries | PN12 | -25°C to 80°C | ISO 9001, REACH | 3 weeks |

Tailored Engineering for Specialized Projects

Top-tier HDPE conduit fittings factories now offer:

- Diameter customization up to 1200mm for offshore wind farms

- Electrofusion joints with embedded RFID tracking chips

- UV-stabilized black HDPE for above-ground solar installations

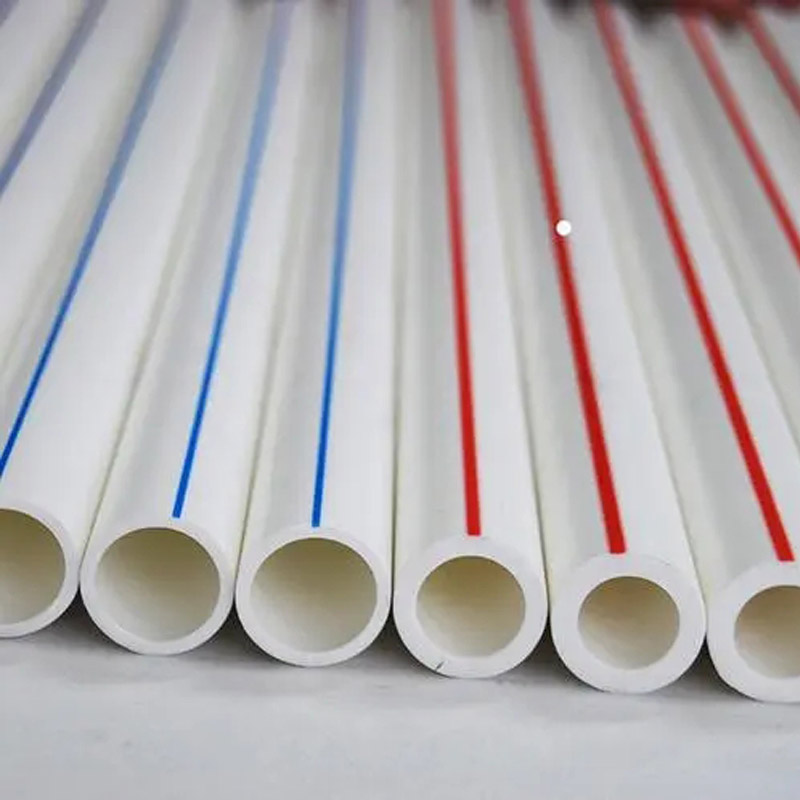

A recent smart city project in Hamburg required color-coded conduits with 90dB acoustic damping – achieved through multi-layer co-extrusion technology.

Proven Success Across Industries

Case Study 1: A telecom giant reduced cable failure rates by 72% after switching to PN16-rated conduit systems in coastal 5G deployments.

Case Study 2: Solar farm operators reported 18% faster installation times using pre-assembled HDPE conduit kits with snap-fit connectors.

Optimizing Installation and Longevity

Proper trenching depth (1.2x pipe diameter) and sand bedding can increase system lifespan by 40%. Annual inspections using pipeline inspection gauges (PIGs) help detect micro-cracks before failure occurs.

Conduit Pipes: Building Tomorrow’s Networks Today

With 5G rollouts and smart grid expansions demanding robust cable protection, HDPE conduit fittings manufacturers are innovating fire-retardant compounds and AI-powered quality control systems. The next-generation pipes will integrate strain sensors for real-time structural health monitoring, revolutionizing infrastructure maintenance.

(conduit pipes)

FAQS on conduit pipes

Q: What are the main advantages of using HDPE conduit pipes?

A: HDPE conduit pipes are lightweight, corrosion-resistant, and durable. They offer excellent flexibility and can withstand harsh environmental conditions. Their long lifespan reduces maintenance costs over time.

Q: How do I choose a reliable HDPE conduit fittings manufacturer?

A: Look for manufacturers with certifications like ISO or UL, proven industry experience, and positive client reviews. Ensure they use high-quality raw materials and provide customized solutions to meet project requirements.

Q: Can HDPE conduit fittings be customized for specific projects?

A: Yes, reputable HDPE conduit fittings factories often offer customization in sizes, colors, and configurations. Provide your project specifications, and they can tailor products to meet structural or environmental needs.

Q: What quality control measures do HDPE conduit fittings factories implement?

A: Top factories conduct rigorous material testing, pressure resistance checks, and dimensional inspections. Many adhere to international standards and perform third-party audits to ensure product reliability and safety.

Q: How long does it take to receive orders from an HDPE conduit fittings factory?

A: Lead times depend on order size and customization. Standard products may ship within 7-14 days, while bulk or custom orders could take 3-6 weeks. Factories with large inventories often expedite deliveries.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025