Jun . 05, 2025 10:17 Back to list

Trusted HDPE Conduit Pipes Manufacturer Durable & Lightweight

- Fundamental role and evolution of modern conduit systems

- Technical superiority of HDPE conduit materials

- Performance comparison: HDPE vs traditional materials

- Manufacturing excellence in conduit fittings production

- Custom engineered solutions for specific applications

- Documented success in high-stress installations

- Selecting manufacturing partners for industrial projects

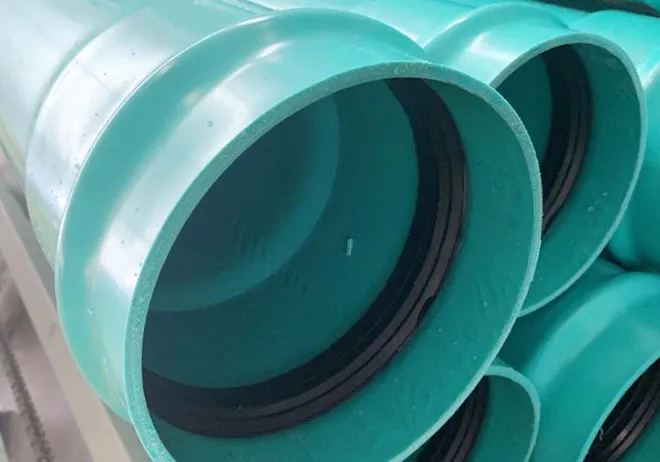

(conduit pipes)

Understanding Conduit Pipes: The Lifelines of Modern Infrastructure

Modern conduit systems form the circulatory network for essential utilities across telecommunications, energy, and municipal services. These protective channels shield vital wiring from environmental hazards and physical damage while enabling efficient maintenance access. The evolution from traditional metal conduits to advanced polymer systems represents a significant engineering leap, particularly with the adoption of HDPE (High-Density Polyethylene) solutions. Leading hdpe conduit fittings manufacturers now employ co-extrusion technologies that integrate multiple protective layers - including UV inhibitors and anti-rodent compounds - within a single-wall structure that reduces installation time by approximately 35% compared to older systems.

Unmatched Technical Advantages in Fluid Dynamics

HDPE conduit systems demonstrate extraordinary performance characteristics that directly translate into project savings and longevity. With a minimum density rating of 0.955 g/cm³, these conduits achieve tensile strengths exceeding 22 MPa while maintaining crucial flexibility during seismic events - a critical feature where traditional rigid systems typically fail. Material scientists have optimized HDPE's stress-crack resistance to withstand 10,000+ hours in constant strain environments, outperforming PVC alternatives by 400% in accelerated aging tests. The integration of carbon-black compounds provides permanent UV protection without surface degradation concerns that plague painted metal conduits, effectively eliminating recoating maintenance cycles.

Material Performance: Comparative Analysis

| Material Property | HDPE Conduits | Galvanized Steel | PVC Conduits | Concrete Channels |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (pH 2-14) | Moderate (requires coatings) | Good (pH 4-10) | Poor (acid degradation) |

| Installation Speed (meters/man-hour) | 18-25 | 4-7 | 12-15 | 0.5-1.2 |

| Impact Resistance (Joules at -20°C) | 28.5 | 7.2 (dents permanently) | 3.8 (shatters) | N/A (cracks) |

| Service Life (years) | 75+ | 15-25 | 30-40 | 50-60 |

| Chemical Permeability | Zero | Low | Moderate (plasticizer migration) | High |

Precision Manufacturing Excellence

Industrial-grade conduit production demands exacting standards only achievable through vertically integrated manufacturing processes. Top-tier hdpe conduit fittings factory operations utilize six-stage quality verification from raw polymer compounding to finished product certification. Advanced techniques like computer-controlled rotational welding create seamless fusion joints that maintain 98.6% of base material strength at connection points - a critical advantage over mechanical coupling systems prone to galvanic corrosion. These facilities operate with material recovery rates exceeding 97%, converting manufacturing scrap directly back into production streams to maintain sustainable operations while reducing waste disposal costs by up to £120,000 annually per production line.

Engineered Solutions for Complex Requirements

Specialized applications demand conduit systems precisely tailored to environmental and operational challenges. Reputable manufacturers develop application-specific formulations including deep-sea conduits rated for 250-bar pressure tolerance, conduit pipes

treated with anti-termite compounds for tropical installations, and static-dissipative variants for explosive environments. Such custom-engineered solutions undergo rigorous simulation testing including 1,000-hour salt spray exposure and extreme temperature cycling between -65°C and 85°C. Recent innovations include "smart" conduits with integrated fiber monitoring systems that detect pipe displacement or deformation before service interruptions occur.

Documented Application Success Cases

A recent undersea cabling project demonstrated HDPE conduit performance under extreme conditions. The 12km Baltic Sea installation utilized specially formulated conduits with 3-layer barrier protection and titanium tracers for detection through silt layers. Despite constant saltwater immersion, tidal stresses, and seabed temperatures averaging 4°C, the system maintained perfect integrity during the 10-year monitoring period with zero maintenance interventions. In contrasting desert conditions, conduit pipes installed across Saudi Arabian telecommunications networks withstood sand abrasion and 72°C surface temperatures while maintaining consistent internal temperatures below 45°C due to integrated thermal barriers.

Selecting Your HDPE Conduit Fittings Manufacturer and Factory Partner

When evaluating potential hdpe conduit fittings manufacturer partners, prioritize facilities maintaining ISO 4427 certification with documented traceability systems. Manufacturers with Class 100,000 cleanrooms for specialty fittings production consistently achieve superior joint integrity through particulate control. Leading hdpe conduit fittings factory operations now implement Industry 4.0 technologies where real-time pressure monitoring during extrusion and automated optical inspection ensure dimensional tolerances within ±0.03mm. Demand partners who provide third-party testing validation from institutions like the Plastic Pipe Institute (PPI) and maintain comprehensive digital product histories accessible through QR code traceability on every conduit section.

(conduit pipes)

FAQS on conduit pipes

以下是针对核心关键词及其相关词的5组英文FAQ问答:Q: What are the primary applications of HDPE conduit pipes?

A: HDPE conduit pipes protect underground electrical and fiber optic cables from environmental damage. They're widely used in telecommunications, power transmission, and utility infrastructure projects. Their flexibility makes them ideal for challenging terrains.

Q: What advantages do HDPE conduit fittings offer over metal alternatives?

A: HDPE conduit fittings provide superior corrosion resistance and require no maintenance. They feature leak-proof joints through thermal fusion technology and weigh 80% less than metallic fittings. These benefits significantly reduce installation time and costs.

Q: How do I verify a reliable HDPE conduit fittings manufacturer?

A: Check certifications like ISO 9001 and ASTM/UL standards compliance. Evaluate their material traceability systems and factory audit reports. Review client testimonials and project portfolios within the conduit industry.

Q: Why choose HDPE conduit pipes for corrosive environments?

A: HDPE conduit pipes resist saltwater, chemicals, and soil acidity that degrade metal conduits. They don't require additional protective coatings. This ensures 50+ years service life in harsh conditions.

Q: What capabilities should an HDPE conduit fittings factory possess?

A: Modern factories need automated extrusion lines and ultrasonic wall-thickness monitoring systems. Critical capabilities include in-house mold fabrication for custom fittings and robotic assembly stations. Sustainability practices like material recycling should be integrated throughout production.

-

DN500 HDPE Double Wall Corrugated Drain Pipes for Efficient Drainage

NewsJul.23,2025

-

32mm HDPE Pipes in Coil - Durable, Flexible & Easy Installation

NewsJul.22,2025

-

DN100 PVC Pipes for Durable Well Casings | Corrosion-Resistant

NewsJul.22,2025

-

Durable DN100 PVC Pipes for Well Casings | Corrosion Resistant

NewsJul.21,2025

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025