Dec . 16, 2024 10:12 Back to list

column pipe for submersible pump products

The Importance of Column Pipe for Submersible Pump Products

Submersible pumps are essential devices widely used in various applications, from agriculture to municipal water supply systems. They function by being submerged in the fluid they are pumping, which allows for efficient operation in deep wells, boreholes, and other challenging environments. An integral component of these pumps is the column pipe, which plays a crucial role in the overall performance and efficiency of the system.

What is a Column Pipe?

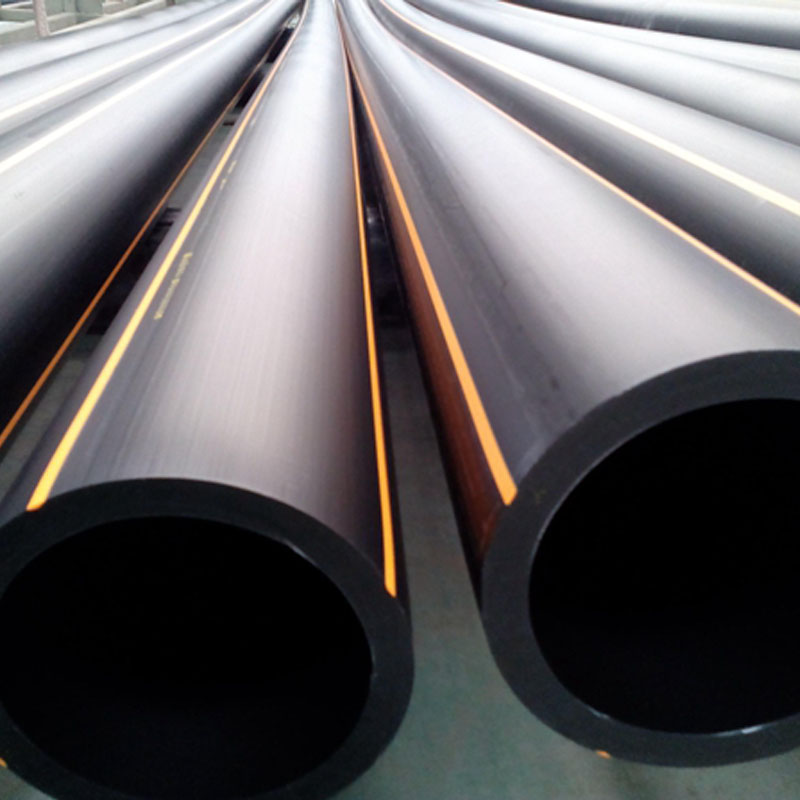

A column pipe, also known as a riser pipe, serves as the conduit through which water is transported from the pump to the surface. It connects the pump's discharge outlet to the tank or surface level, ensuring the smooth transfer of fluids. Typically manufactured from durable materials such as stainless steel, PVC, or ductile iron, column pipes are designed to withstand high pressure and corrosion, ensuring a long service life.

Design Considerations

The design and selection of column pipes are vital for maximizing the efficiency and longevity of submersible pumps. The diameter of the column pipe must match the pump's discharge size to prevent turbulence and pressure loss. Additionally, the pipe's material should be chosen based on the characteristics of the fluid being pumped and the environment in which it operates. For instance, stainless steel is often preferred for its resistance to corrosion and mechanical stress, while PVC is a cost-effective option for less demanding applications.

Another critical design consideration is the length of the column pipe. The height from which the pump needs to lift the water significantly influences the selection of the column pipe. Generally, the longer the column pipe, the more resistance it will encounter, possibly leading to reduced flow rates and efficiency. Consequently, manufacturers must balance the column pipe length with the application's specific requirements.

Importance of Proper Installation

column pipe for submersible pump products

Proper installation of column pipes is equally important as their design. A poorly installed column can lead to various issues, including leaks, pressure loss, and even pump failure. It is essential to ensure that all connections are sealed appropriately to prevent water ingress, which can lead to costly repairs and downtime. Additionally, support structures must be in place to maintain the pipe's integrity, especially in deep installations where the weight of the water column poses a significant challenge.

Maintenance and Monitoring

Regular maintenance of both the column pipe and submersible pump is critical to ensuring long-term reliability and performance. Inspecting the column pipe for signs of wear and tear, corrosion, or blockages can prevent potential failures. Moreover, monitoring the pump's operation, including flow rates and energy consumption, can help detect inefficiencies early. Any abnormalities should be addressed promptly to avoid more severe complications.

Innovations and Advancements

With advancing technology, there have been innovations in the design and materials used for column pipes. Manufacturers are now exploring composite materials that offer enhanced strength-to-weight ratios and resistance to corrosive environments. Moreover, smart monitoring systems integrated into pumping systems allow for real-time data analysis, ensuring optimal performance and early identification of issues.

Conclusion

In summary, the column pipe is a fundamental component in the functionality of submersible pumps. Its design, material choice, and proper installation are paramount in ensuring efficient operation, reducing maintenance costs, and prolonging the lifespan of the pumping system. As the demand for reliable water supply solutions continues to grow, understanding and optimizing column pipe for submersible pump applications will be essential for engineers and operators alike. Investing in quality materials and rigorous maintenance practices will undoubtedly yield significant benefits in efficiency and sustainability in various industries reliant on submersible pumping systems.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025