Nov . 03, 2024 20:15 Back to list

column pipe for submersible pump product

Understanding Column Pipe for Submersible Pumps

Submersible pumps have become an essential component in various industries, from agricultural irrigation to municipal water supply and wastewater management. Among the critical components of these pumps is the column pipe, which plays a significant role in their functionality and efficiency.

What is a Column Pipe?

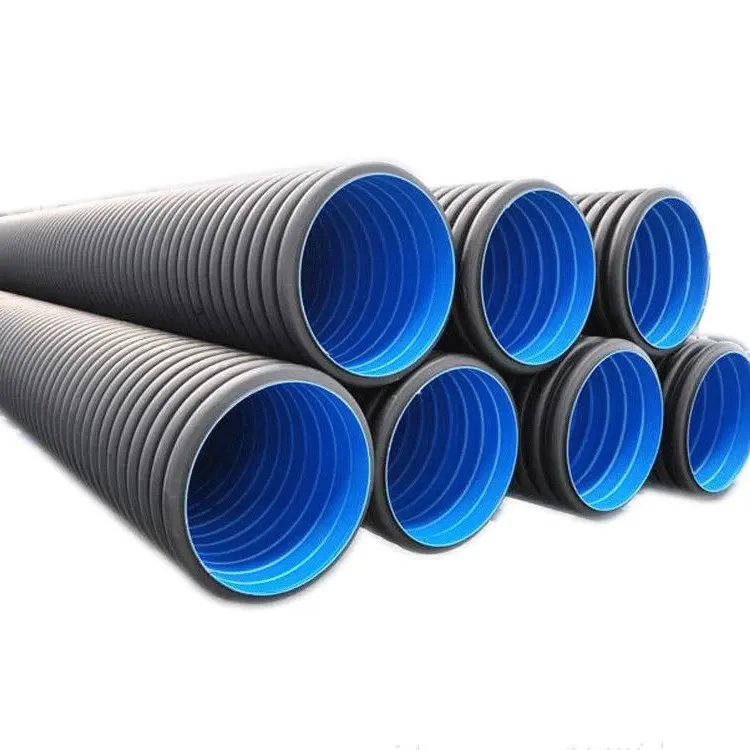

A column pipe is a vertical pipe that connects the submersible pump to the surface level, facilitating the transportation of fluids from beneath the water table to the desired location above ground. It serves as a conduit for water, typically made from materials such as stainless steel, PVC, or HDPE, depending on the specific requirements of the application and the nature of the fluid being pumped.

Importance of Column Pipes

1. Fluid Transport The primary function of a column pipe is to transport water or other fluids efficiently. The diameter and material of the column pipe are crucial in minimizing friction losses and ensuring optimal flow rates. A well-sized and constructed column pipe can significantly enhance the overall performance of the submersible pump.

column pipe for submersible pump product

2. Pressure Management Column pipes also help in managing pressure within the pumping system. The design must accommodate the hydraulic forces generated during operation to prevent leaks, bursts, or collapses. The correct choice of pipe material and thickness ensures durability and reliability, allowing the pump to operate at varying depths and pressures.

3. Installation and Maintenance The installation of column pipes should be conducted with care to ensure they are sealed and aligned correctly. Proper maintenance routines are vital to avoid issues such as wear and tear, which can lead to inefficiencies or breakdowns over time. Regular inspections help to identify and resolve potential problems before they escalate.

4. Corrosion Resistance Given that many submersible pumps are used in corrosive environments, selecting the right materials for column pipes is critical. Stainless steel is often favored for its high corrosion resistance, while PVC and HDPE provide a cost-effective alternative for less demanding applications. The choice of material impacts both longevity and maintenance costs.

5. Application Versatility Column pipes are versatile components that can be tailored to suit various applications. Different sizes, lengths, and configurations are available to meet the needs of both residential and industrial users, ensuring compatibility with a wide range of submersible pump designs.

Conclusion

In conclusion, the column pipe is a vital element in the operation of submersible pumps, contributing to the efficiency, reliability, and overall success of fluid transport systems. Understanding its functions, importance, and maintenance requirements can lead to improved performance and extended service life of both the column pipe and the submersible pump it supports. As technology progresses, innovations in the design and materials used for column pipes will continue to enhance their functionality in a world that increasingly relies on efficient water management solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025