Sep . 05, 2024 09:17 Back to list

Column Pipe for Submersible Pump Factories | High-Quality Solutions

The Role of Column Pipe in Submersible Pump Manufacturing

Submersible pumps are integral components in various industries, including agriculture, mining, and wastewater management. Central to the efficiency and functionality of these pumps is the column pipe, a crucial element that connects the pump to the surface. Understanding the significance of column pipes in submersible pump factories helps appreciate their role in enhancing pump performance and durability.

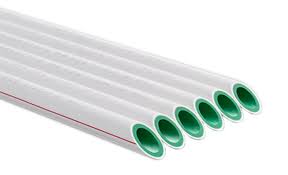

Column pipes are typically made of durable materials such as stainless steel, PVC, or HDPE, which are resistant to corrosion and wear. This sturdy construction is essential, considering that these pipes often operate submerged in water or other liquids. The design of column pipes must account for factors such as fluid pressure, temperature variations, and chemical compositions to ensure the long-term reliability of submersible pumps.

The manufacturing process of column pipes involves several critical steps. Initially, raw materials are selected based on their mechanical properties and resistance to environmental conditions. The production process requires precision engineering to produce pipes with uniform dimensions and thickness, ensuring they can withstand the pressures experienced during operation.

Quality control is paramount in the manufacturing of column pipes. Factories implement rigorous testing procedures, including pressure testing and material analysis, to verify the structural integrity and performance of the pipes. These tests help prevent failures that could lead to costly downtime or repairs in the field.

column pipe for submersible pump factories

Besides durability, the design of column pipes also plays a role in minimizing friction losses. Streamlined interior surfaces reduce turbulence as fluids pass through, enhancing the overall efficiency of submersible pumps. This design consideration is vital for operations that rely on the effective movement of fluids, such as irrigation systems or municipal water supplies.

Another important aspect is the connection of column pipes to submersible pumps and discharge heads. Proper sealing and alignment are essential to prevent leaks and ensure optimal performance. Factories often design column pipes with standard fittings and couplings to allow for easier installation and maintenance.

In recent years, advancements in technology and materials have enhanced the production of column pipes for submersible pumps. Innovations like advanced composite materials provide alternatives that combine strength with lightweight characteristics, offering greater flexibility in design without compromising performance.

In conclusion, column pipes are essential to submersible pump factories, driving efficiency and functionality in fluid management systems. Their robust construction, precise manufacturing, and design considerations significantly impact the overall performance of submersible pumps. As industries continue to evolve, the importance of high-quality column pipes will remain paramount in ensuring reliable and effective pumping solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025