Jan . 20, 2025 05:32 Back to list

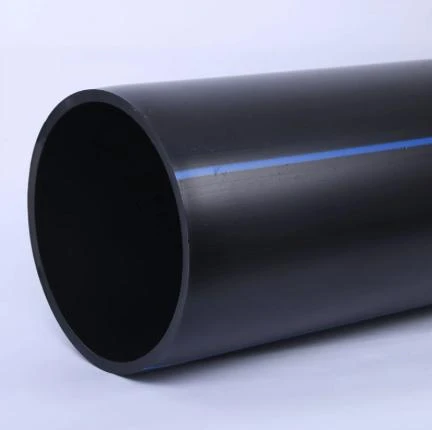

china hdpe to steel coupling

China's commitment to sustainable development amplifies the appeal of its HDPE to steel offerings. The manufacturing processes employ eco-friendly techniques, resulting in products that are as responsible as they are reliable. The lifecycle of HDPE to steel couplings is designed to minimize environmental impact, aligning with global efforts to create more sustainable industrial solutions. Case studies highlighting successful implementations add another layer of reliability to these products. For instance, a large-scale irrigation project in Southeast Asia documented significant improvements in efficiency following the switch to HDPE to steel couplings from China. The transition led to increased water conservation due to reduced leakages and provided a robust system capable of withstanding environmental challenges such as earthquakes and soil erosion. These tangible results are a testament to the coupling's superior performance. Professionals in the pipeline industry regard these couplings as a testament to China's engineering expertise and its commitment to quality. As infrastructure demands rise globally, the HDPE to steel coupling represents a smart investment for stakeholders seeking performance-enhanced and long-term solutions. The continuous feedback loop between users and manufacturers ensures that product improvements are ongoing, further bolstering trust and satisfaction among end-users. Investing in Chinese HDPE to steel couplings is not just a decision based on current needs—it is a forward-looking choice intertwined with the promise of future-proof infrastructure. The engineering acumen and authoritative presence that China commands in the sector continue to innovate and refine coupling technologies, setting benchmarks that others attempt to follow. The global stage recognizes these developments, reinforcing China's standing as a pivotal player in advancing worldwide industrial standards. In summary, HDPE to steel couplings epitomize the convergence of material science and industrial application, offering unparalleled advantages in the coupling domain. China's strategic expertise, coupled with a commitment to quality and sustainability, positions its HDPE to steel couplings as the preferred choice for industries aiming for excellence and resilience in their operations.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025