Nov . 13, 2024 14:27 Back to list

china hdpe to pvc coupling

The Transition from HDPE to PVC Couplings in China A Comprehensive Overview

In the ever-evolving landscape of piping solutions, the transition from High-Density Polyethylene (HDPE) to Polyvinyl Chloride (PVC) couplings in China is a significant topic worthy of exploration. Both materials have carved their niches in various sectors, but understanding the dynamics of their comparison, advantages, and applications is critical for industry stakeholders.

Understanding HDPE and PVC

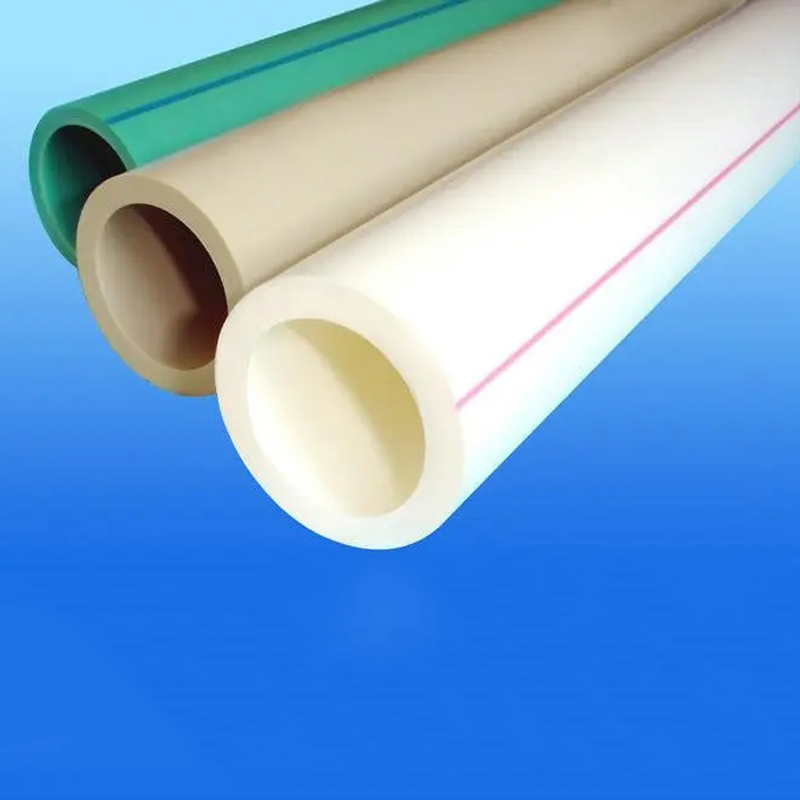

High-Density Polyethylene, or HDPE, is a thermoplastic polymer known for its high strength-to-density ratio. It is highly resistant to impact and has excellent chemical resistance, making it ideal for demanding applications such as water and gas pipelines, industrial storage, and even agricultural purposes. HDPE's flexibility and durability have made it a popular choice in construction and manufacturing.

On the other hand, Polyvinyl Chloride, commonly known as PVC, is one of the most widely used synthetic plastics globally. It is not only versatile and durable but also relatively affordable. PVC’s resistance to environmental degradation also contributes to its widespread use in plumbing, electrical insulation, and even consumer products.

The Advantages of HDPE Couplings

HDPE couplings are often preferred for their robustness and ability to withstand extreme conditions. They are lightweight, easy to install, and can handle pressures that many other materials cannot. Additionally, HDPE is known for its longevity, with lifespans extending over several decades. These features make HDPE couplings particularly appealing in water distribution networks where reliability is paramount.

Furthermore, HDPE can be recycled, aligning with global sustainability practices. As industries lean towards sustainable solutions, HDPE's recyclability gives it a competitive edge in environmentally conscious markets.

The Shift toward PVC Couplings

Despite the clear advantages of HDPE, the shift towards PVC couplings in China is noteworthy. One of the primary reasons for this transition is cost-efficiency. PVC is generally less expensive to produce than HDPE, making it a more attractive option for many companies, particularly in a competitive market like China.

china hdpe to pvc coupling

Additionally, PVC couplings offer excellent ease of installation. The lightweight nature of PVC allows for faster handling and reduced labor costs on construction sites. Moreover, PVC’s superior adaptability to various joint types and accessories further enhances its appeal to contractors and engineers.

Challenges and Considerations

The transition from HDPE to PVC couplings is not without challenges. One significant concern lies in the environmental impact. While PVC is durable, its production process involves harmful chemicals, and it is less sustainable than HDPE. As global awareness of environmental issues increases, companies are faced with the task of balancing the benefits of cost and efficiency with the responsibility of sustainable practices.

Moreover, while PVC has certain advantages, its potential brittleness and susceptibility to UV radiation pose risks in specific applications. HDPE’s resilience in extreme weather conditions, along with its overall impact resistance, often makes it the more reliable option in specific scenarios.

The Future of Couplings in China

Looking ahead, the choice between HDPE and PVC couplings will likely be influenced by evolving industry standards, regulatory changes, and increasing environmental concerns. As China aims to enhance its infrastructure and urbanization efforts, policymakers and industry leaders must consider the long-term implications of their choices regarding materials.

Innovation will also play a crucial role. Advances in polymer technology may pave the way for new coupling solutions that combine the strengths of both HDPE and PVC. For instance, hybrid materials or improved composite couplings may offer enhanced performance characteristics that meet diverse application requirements.

Conclusion

The transition from HDPE to PVC couplings in China is a multifaceted issue that encapsulates economic, environmental, and practical considerations. While both materials have their distinct advantages, the choice between them will depend on specific applications, cost considerations, and sustainability practices. As the industry continues to evolve, staying informed about these trends will be crucial for stakeholders looking to make the best decisions for their projects. The future of piping solutions in China holds promise, and understanding these dynamics will undoubtedly shape the landscape for years to come.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025