Nov . 21, 2024 03:56 Back to list

china hdpe pipe pdf

Understanding China HDPE Pipe Production and Applications

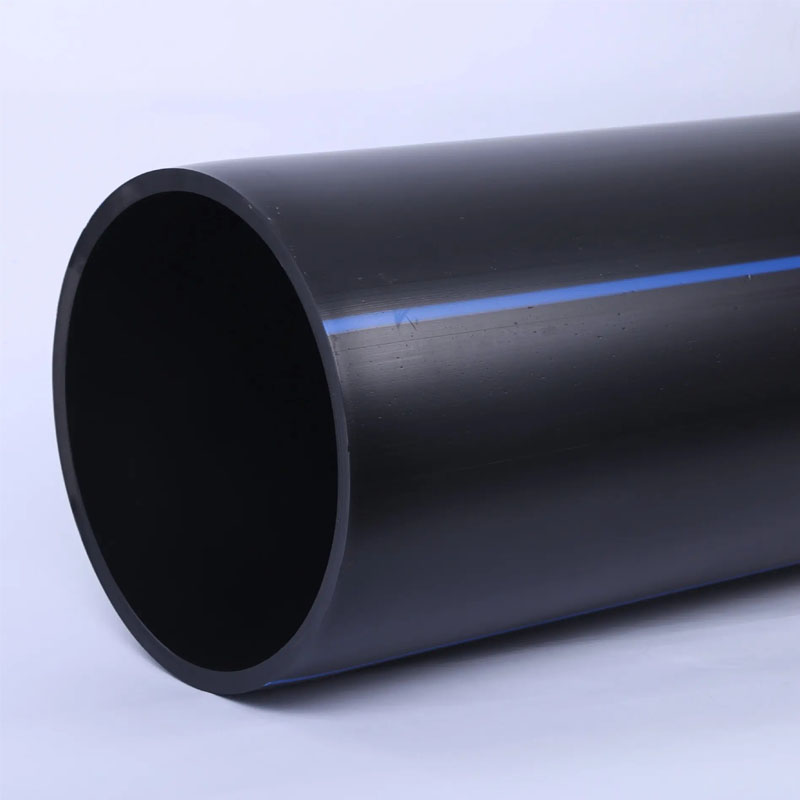

High-Density Polyethylene (HDPE) pipes have gained substantial popularity in various industries due to their outstanding durability, lightweight nature, and excellent corrosion resistance. In recent years, China has emerged as one of the prominent producers of HDPE pipes, catering to both domestic and international markets. This article delves into the characteristics, production processes, and applications of HDPE pipes manufactured in China.

Characteristics of HDPE Pipes

HDPE pipes are known for their remarkable physical and chemical properties. Firstly, they possess high tensile strength and impact resistance, making them suitable for demanding environments. Unlike traditional materials like metal and concrete, HDPE does not corrode or rust, significantly extending its lifespan. Furthermore, these pipes are resistant to a wide range of chemicals, which makes them ideal for transporting hazardous materials without the risk of contamination.

Another significant advantage of HDPE pipes is their flexibility. This feature allows for easier installation, especially in areas with challenging terrain. Additionally, HDPE pipes are lighter than their metal counterparts, reducing transportation costs and labor intensity during installation.

Production Processes in China

China's HDPE pipe production involves advanced technology and processes to ensure high-quality output. The manufacturing process typically starts with the selection of high-grade polyethylene resin as the primary raw material. This resin is then subjected to processes such as extruding, molding, and cooling to form pipes of various diameters and wall thicknesses.

china hdpe pipe pdf

Chinese manufacturers often utilize automated production lines that enhance efficiency and reduce human error. Quality control is a critical aspect of the production process, with many manufacturers adhering to international standards such as ISO 9001. This commitment to quality ensures that Chinese HDPE pipes meet the stringent requirements of various industries.

Applications of HDPE Pipes

The versatility of HDPE pipes allows them to be used in a wide range of applications. One of the most common uses is in water supply systems, where their resistance to corrosion and scale build-up ensures the safe transportation of potable water. Additionally, HDPE pipes are extensively used in sewage and drainage systems due to their ability to withstand harsh environmental conditions.

In the agricultural sector, HDPE pipes play a vital role in irrigation systems. Their flexibility and resistance to UV radiation make them suitable for surface and subsurface irrigation applications. Furthermore, in recent years, HDPE pipes have gained traction in the telecommunications industry, where they are used for conduit applications to house fiber optic cables.

Conclusion

In conclusion, China stands out as a key player in the production of HDPE pipes, driven by advanced manufacturing processes and stringent quality control measures. The unique properties of HDPE pipes, such as durability, flexibility, and chemical resistance, make them suitable for diverse applications ranging from water supply to telecommunications. As industries continue to recognize the benefits of HDPE, the demand for these pipes is expected to rise, further solidifying China's position in the global market. Whether for infrastructure development or agricultural needs, HDPE pipes offer reliable solutions to modern challenges, paving the way for sustainable and efficient operations across various sectors.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025