Dec . 05, 2024 01:57 Back to list

china hdpe pipe for water supply specifications

HDPE Pipe for Water Supply Specifications, Benefits, and Applications

High-Density Polyethylene (HDPE) pipes have become increasingly popular for water supply systems due to their numerous advantages over traditional materials. HDPE pipes offer durability, corrosion resistance, and ease of installation, making them a preferred choice for various applications. This article aims to delve into the specifications of HDPE pipes used for water supply and highlight their benefits and applications.

Specifications of HDPE Pipes

HDPE pipes for water supply are manufactured according to specific industry standards. These specifications ensure that the pipes meet the necessary requirements for pressure ratings, dimensions, materials, and performance criteria. Here are some key specifications to consider

1. Material HDPE is a thermoplastic made from petroleum, characterized by its high strength-to-density ratio. The material is resistant to physical stress and can withstand harsh environmental conditions.

2. Diameter and Thickness HDPE pipes are available in various diameters, typically ranging from 16 mm to 1,200 mm, ensuring that they can be used for both small and large-scale water supply systems. The wall thickness of the pipes can vary based on the application, with standard thicknesses prescribed in industry norms, such as ASTM D3035 and ISO 4427.

3. Pressure Rating The pressure rating of HDPE pipes is crucial for determining their applicability in different conditions. Common pressure ratings include PN 6, PN 8, PN 10, PN 12.5, and PN 16, which indicate the maximum pressure the pipe can withstand in bars. Selecting the appropriate pressure rating based on the intended usage is vital for ensuring system integrity.

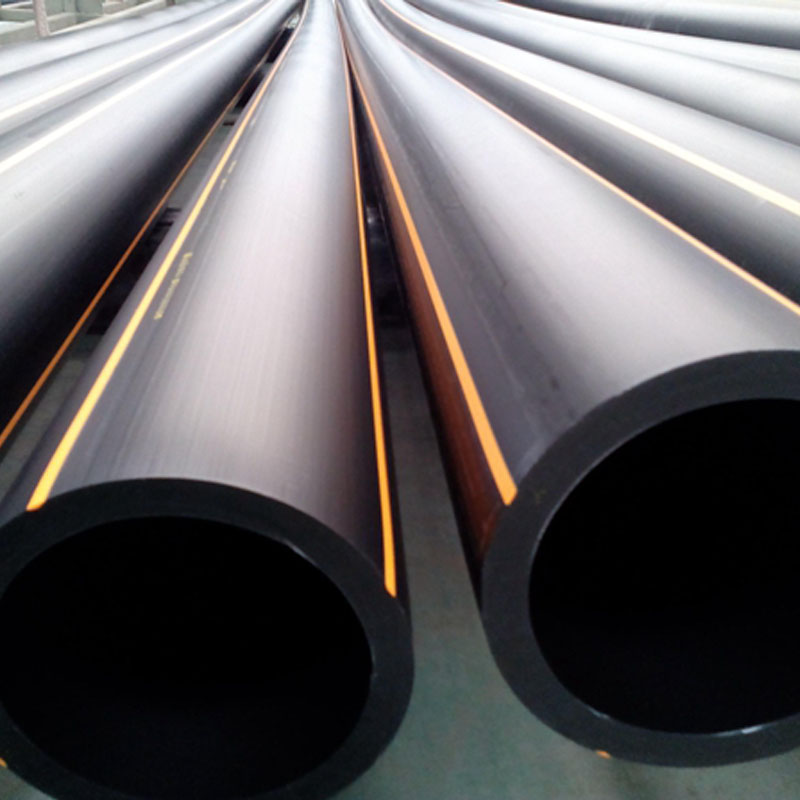

4. Color Coding Many HDPE pipes come with distinct color codes to signify their specific uses. For instance, blue HDPE pipes are often utilized for potable water supply, while black pipes may indicate industrial applications.

5. Joining Methods HDPE pipes can be joined using various techniques, including butt fusion, electrofusion, and mechanical fittings. These methods ensure a strong, leak-proof connection that is essential for maintaining the integrity of water supply systems.

Benefits of HDPE Pipes

1. Corrosion Resistance One of the primary advantages of HDPE pipes is their resistance to corrosion. Unlike metal pipes, which can rust and degrade over time, HDPE pipes maintain their structural integrity, leading to longer service life and reduced maintenance costs.

2. Flexibility and Lightweight HDPE pipes are highly flexible and can be easily transported and installed. They can withstand ground movements and settle without cracking, making them ideal for applications in regions prone to soil shifts.

china hdpe pipe for water supply specifications

3. Low Friction Coefficient The smooth interior surface of HDPE pipes results in a low friction coefficient, which promotes efficient water flow and reduces energy costs for pumping systems.

4. Environmental Impact HDPE is environmentally friendly and can be recycled at the end of its lifecycle. The production of HDPE pipes generates fewer carbon emissions compared to traditional materials, making it a more sustainable choice for water distribution systems.

5. Resistance to Chemicals HDPE pipes can handle a wide range of chemicals without deteriorating, making them suitable for various applications beyond water supply, including wastewater, irrigation, and industrial uses.

Applications of HDPE Pipes

HDPE pipes are utilized in a variety of applications, demonstrating their versatility and reliability

1. Potable Water Supply HDPE pipes are the preferred material for potable water distribution systems in both urban and rural areas due to their safety and durability.

2. Irrigation Systems Farmers have increasingly adopted HDPE pipes for agricultural irrigation due to their efficiency and ability to deliver water directly to crop roots.

3. Wastewater Management HDPE pipes are commonly used in the construction of sewage and drainage systems, where their resistance to chemicals and sediments is essential.

4. Industrial Applications Industries utilize HDPE pipes for transporting various liquids and gases, benefiting from their strength and resistance to corrosion.

Conclusion

HDPE pipes for water supply offer a reliable, cost-effective solution for modern water distribution and management systems. With their superior specifications and a broad range of applications, they provide numerous benefits that meet the demands of both residential and industrial uses. As communities continue to seek sustainable infrastructure solutions, HDPE pipes will undoubtedly play a vital role in shaping the future of water supply systems worldwide.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025