Jan . 09, 2025 13:53 Back to list

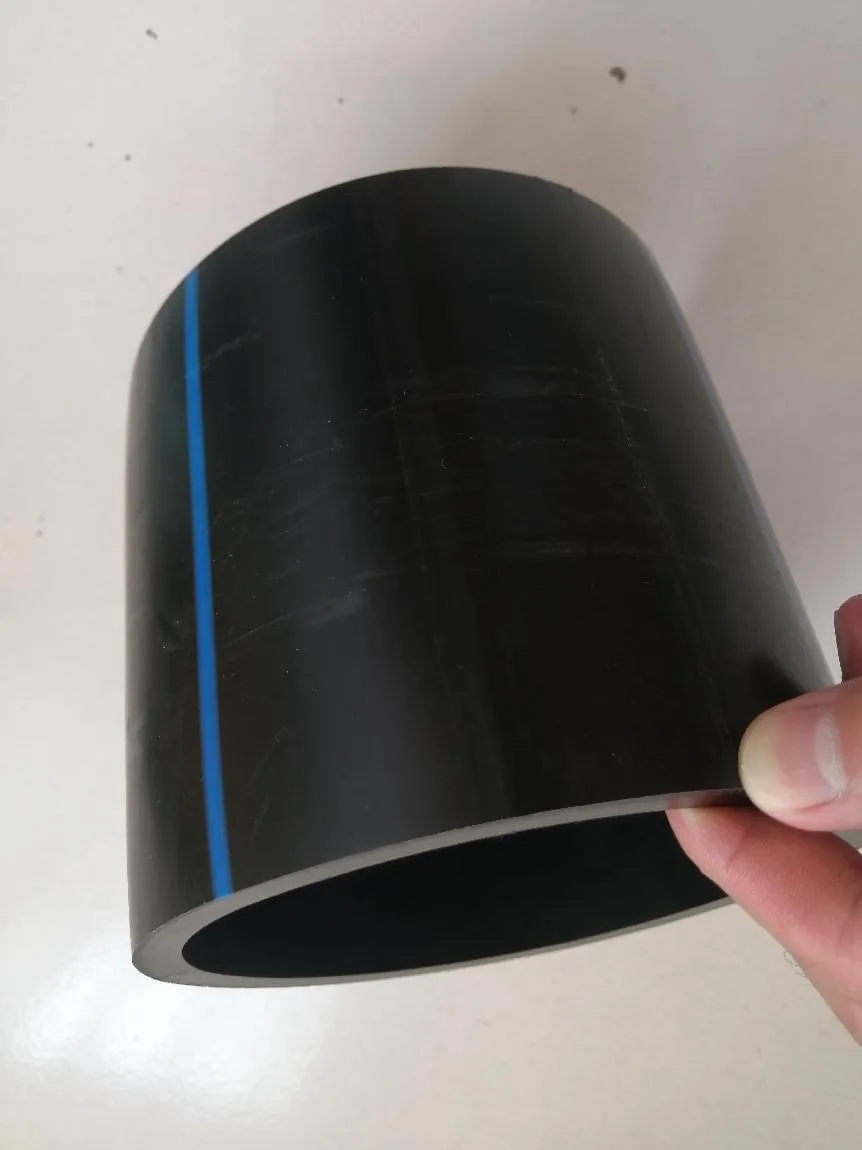

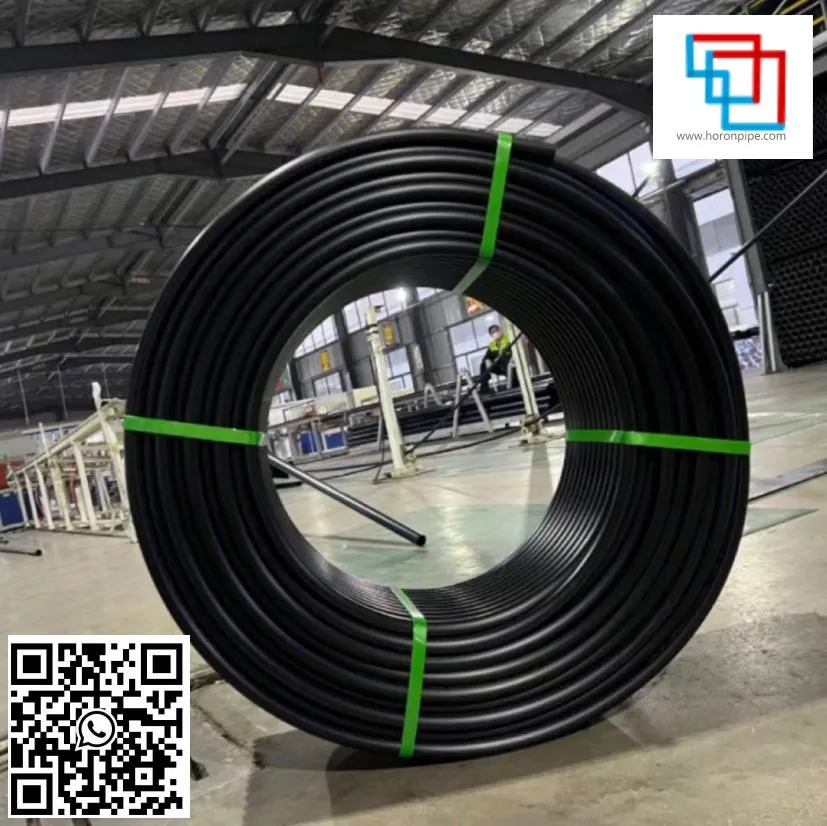

DN150 HDPE pipes for irrigation

The trust placed in HDPE connectors is substantiated by rigorous industry standards and certifications that guide their production and application. Compliance with international quality standards such as ISO 4427 and ASTM D3350 ensures that these connectors meet the stringent requirements for safety and performance. This adherence not only reinforces their reputation but also provides clients with the assurance of quality and reliability. Real-world experience from field engineers and feedback from installations further reinforce the excellence of HDPE connectors. Reports highlight the ease of installation, with many installations requiring no heavy machinery, reducing setup times and costs. Additionally, the lightweight nature of HDPE allows for easier handling and transport, vital in complex projects where logistics play a crucial role. The strategic use of HDPE in eco-friendly projects also aligns with ongoing environmental initiatives globally. As industries seek green solutions, the recyclable nature of HDPE positions it as a future-forward choice that minimizes environmental impact. By choosing HDPE, industries not only benefit from superior performance but also contribute to sustainable practices, which is increasingly becoming a decisive factor for collaborators and stakeholders. In summary, the engineering innovation behind HDPE pipe connectors has established them as essential components in modern piping networks. With proven durability, environmental resistance, and compliance with international standards, they offer unmatched benefits that align with contemporary technical and ecological needs. For industry leaders and technical experts, HDPE pipe connectors represent not just a product, but a strategic solution to the challenges of modern infrastructure.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025