Jan . 20, 2025 13:28 Back to list

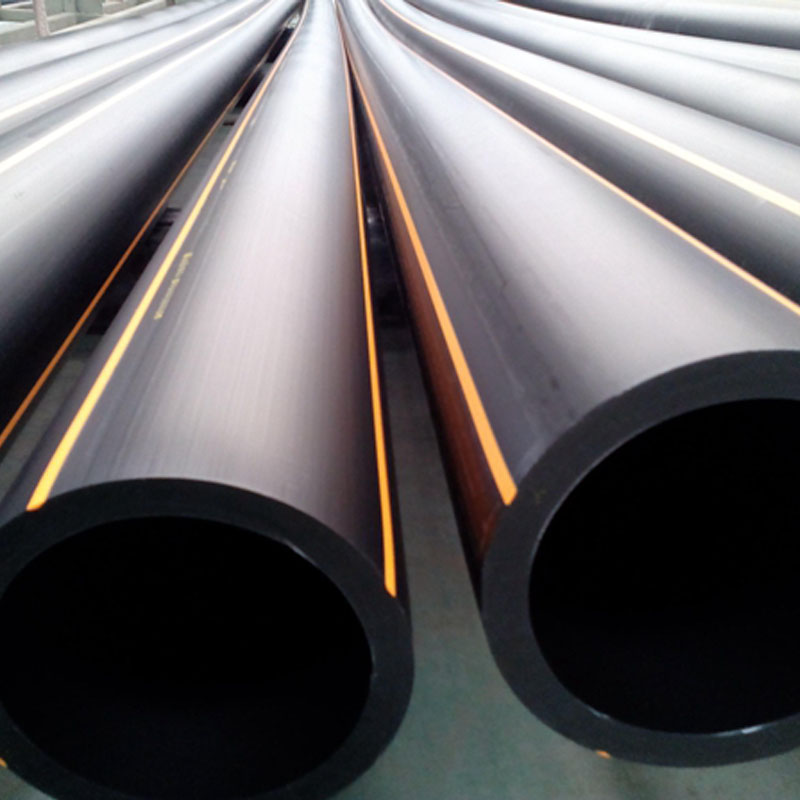

DN150 HDPE pipes for irrigation

From a cost perspective, the initial investment in HDPE pipes may appear substantial compared to other piping materials. However, when considering the total cost of ownership – including installation, maintenance, and operational efficiency – HDPE pipes often come out as the more economical choice. Many case studies in the industry have underscored how the upfront higher costs balance out over time through reduced water loss, lower maintenance, and extended pipe lifespan. The authority in the industry has driven the standardization and adoption of HDPE pipes. Given their effectiveness, many governments and industry bodies now recommend them for numerous applications, from large-scale municipal water systems to specialized industrial uses. This advocacy underscores the pipes' reliability and effectiveness, contributing to the trustworthiness HDPE pipes enjoy in the marketplace. When contemplating the cost of 48-inch HDPE pipes, it is vital to factor in both the initial investment and the long-term savings they offer. According to professionals and project managers experienced with these systems, the benefits they provide in terms of durability, efficiency, and reduced risk of failure frequently justify the investment. With a clear understanding of the long-term benefits and savings, it becomes evident why HDPE pipes are regarded as a strategic investment for infrastructure projects worldwide. Their usage showcases a blend of innovative engineering and practical application that meets the demands of contemporary construction and infrastructure development requirements. In conclusion, while the initial cost of 48-inch HDPE pipes might seem high, their multitude of benefits, particularly concerning longevity and efficiency, make them a cost-effective solution in the long run. They exemplify a product that adheres to experience-driven insights, professional expertise, authoritative recommendations, and a high degree of trustworthiness in application, providing a compelling case for their continued and expanding use in various industries.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025