Dec . 07, 2024 08:48 Back to list

China 2012 Double-Wall Corrugated Pipe Industry Overview and Market Trends Analysis

The Rise of Double Wall Corrugated Pipes in China A 2012 Perspective

In recent years, the construction and infrastructure industries in China have experienced rapid growth, paralleling the country’s remarkable economic development. Among the advancements in materials utilized in these sectors, double wall corrugated (DWC) pipes have emerged as an essential component, particularly in stormwater management, sewage systems, and various civil engineering applications. This article explores the significance, benefits, and applications of double wall corrugated pipes within the Chinese context, with a particular focus on trends observed in 2012.

Double wall corrugated pipes consist of two layers an outer wall that is typically corrugated, adding strength and stiffness, and an inner wall which is smooth to facilitate the flow of liquids. This design not only enhances the pipe's structural integrity but also minimizes friction, allowing for efficient fluid transport. The dual-wall system is particularly advantageous in various environmental conditions, making these pipes suitable for a wide range of applications.

The Rise of Double Wall Corrugated Pipes in China A 2012 Perspective

Another factor driving the demand for double wall corrugated pipes was a heightened awareness of environmental sustainability. In 2012, China placed a greater emphasis on sustainable construction practices, and DWC pipes, made from recycled materials and offering longevity, aligned perfectly with this ethos. Their lightweight nature not only allows for easier transportation and installation but also results in lower carbon emissions during production and deployment, appealing to environmentally conscious stakeholders.

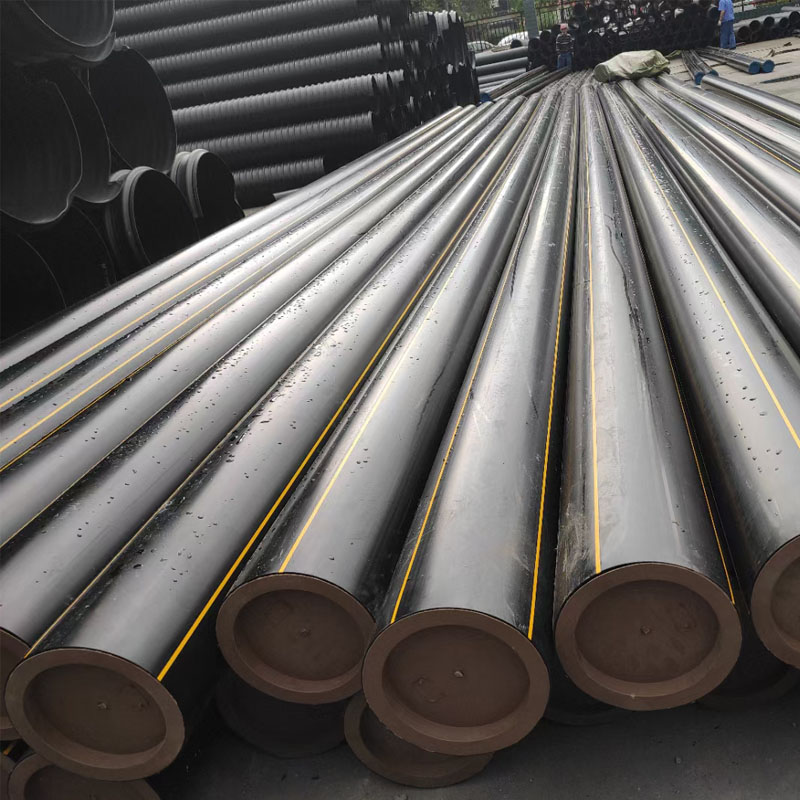

china 12 double wall corrugated pipe

The economic benefits of using double wall corrugated pipes cannot be overstated. Their resistance to corrosion, abrasion, and other forms of deterioration translates to reduced maintenance costs over time. In an era where budgets are often constrained, the long-term financial savings associated with DWC pipes make them an attractive option for both public and private sectors.

In terms of technical specifications, double wall corrugated pipes are available in a range of sizes and configurations, accommodating various project requirements. In 2012, advances in manufacturing technology allowed for better quality control and the production of pipes that meet national and international standards. This led to increased confidence among engineers and planners, who began to advocate for DWC pipes in infrastructure designs more robustly.

Moreover, by this time, several Chinese manufacturers had begun to dominate the market for double wall corrugated pipes, developing a portfolio of products that showcased innovative designs and materials. The government also played a pivotal role in driving growth through regulations that encouraged the use of modern plumbing solutions to enhance public health and infrastructure efficiency. The push for adherence to environmental regulations, specifically, led to increased investments in research and development of new materials and technologies, further boosting the DWC pipe segment.

As 2012 progressed, the collaboration between government, industry stakeholders, and academic institutions worked harmoniously to foster advancements in the application of double wall corrugated pipes. Various pilot projects were launched across cities in China, demonstrating the efficacy and reliability of these pipes in real-world scenarios. These initiatives helped to build public trust and acceptance, paving the way for wider adoption of DWC technology.

In conclusion, the year 2012 marked a dynamic period for the development and implementation of double wall corrugated pipes in China. Their numerous advantages—ranging from structural integrity and cost-effectiveness to environmental sustainability—positioned them as a critical component in the nation’s infrastructure strategy. As urbanization continues to rise and environmental challenges persist, the importance of utilizing efficient and innovative solutions like DWC pipes will only grow, highlighting their potential in shaping the future of construction and drainage systems in China.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025