Dec . 19, 2024 23:40 Back to list

bulk pvc pipe manufacturers

The Growing Market of Bulk PVC Pipe Manufacturers

In the realm of construction and plumbing, polyvinyl chloride (PVC) pipes have emerged as a popular choice due to their durability, corrosion resistance, and versatility. As infrastructure development accelerates worldwide, the demand for bulk PVC pipe manufacturers has surged remarkably. This article delves into the factors driving the growth of the PVC pipe industry, the advantages of using PVC pipes, and the challenges faced by manufacturers.

Understanding PVC Pipes

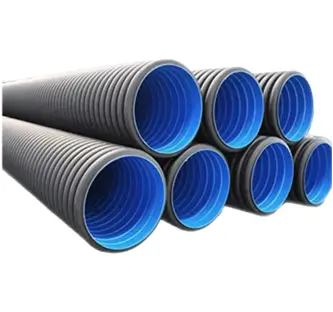

PVC pipes are thermoplastic pipes made from polyvinyl chloride. They are widely used in various applications, including plumbing, drainage, sewage, irrigation, electrical conduits, and telecommunications. Known for their strength and longevity, PVC pipes are resistant to chemical corrosion, making them suitable for a variety of environments, especially where metal pipes may corrode.

The manufacturing process of PVC pipes involves the polymerization of vinyl chloride monomer (VCM), followed by extrusion, which shapes the molten PVC into pipe form. The resulting product can be rigid or flexible, depending on the intended application. Bulk PVC pipe manufacturers often produce pipes in large quantities to meet the demands of the construction industry, providing an array of sizes and specifications.

Drivers of Market Growth

The rising global population and urbanization have led to increased construction activities, driving demand for bulk PVC pipes. Governments are investing heavily in infrastructure projects, including water supply and sewage systems, which rely on durable piping solutions. Additionally, the growth of the agricultural sector has propelled the demand for irrigation systems, where PVC pipes play a crucial role.

Moreover, the cost-effectiveness of PVC pipes compared to traditional materials such as metal or concrete serves as a compelling factor for builders and contractors. PVC pipes are lighter, easier to install, and require less maintenance over time. Their longevity translates into lower replacement and repair costs, making them an attractive option for large-scale projects.

Advantages of Using PVC Pipes

bulk pvc pipe manufacturers

One of the most significant advantages of PVC pipes is their resistance to chemical corrosion. This property makes them ideal for transporting a variety of substances, including potable water, wastewater, and agricultural chemicals. PVC pipes do not rust, rot, or corrode, ensuring a longer service life and reducing the need for replacement.

Additionally, PVC pipes have smooth internal surfaces that minimize friction loss, allowing for efficient fluid transport. They also exhibit good thermal insulation properties, which can be advantageous in certain applications. The lightweight nature of PVC makes it easier to handle and transport, contributing to lower labor costs and faster project completion times.

The ease of installation of PVC pipes is another crucial advantage. Unlike traditional piping materials that may require welding or specialized fittings, PVC pipes can be joined using solvent cement or mechanical fittings, simplifying the installation process significantly.

Challenges Faced by Manufacturers

Despite the numerous advantages, bulk PVC pipe manufacturers face several challenges. One of the primary concerns is the environmental impact of PVC production. The manufacturing process involves the use of VCM, which is toxic and poses environmental risks if not managed properly. Consequently, there is a growing demand for sustainable practices within the industry.

Additionally, the global shift towards eco-friendly materials means that manufacturers need to innovate and adapt to changing regulations and consumer preferences. Biodegradable and recycled alternatives to traditional PVC are emerging, prompting manufacturers to invest in research and development to remain competitive.

Moreover, fluctuations in raw material prices can affect profit margins for manufacturers. The cost of producing PVC pipes can vary based on the prices of crude oil and other petrochemicals, necessitating strategic planning and efficient operations to mitigate these challenges.

Conclusion

The market for bulk PVC pipe manufacturers is on an upward trajectory, driven by urbanization, infrastructure development, and the advantages of PVC materials in construction. While the industry faces challenges related to environmental sustainability and material costs, the demand for reliable and durable piping solutions continues to grow. As manufacturers evolve to meet these challenges, the future of PVC pipes looks promising, providing essential infrastructure for a modern society. In this dynamic landscape, collaboration and innovation will be key for manufacturers seeking to thrive in a competitive market.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025