Dec . 24, 2024 18:16 Back to list

Top Manufacturer of 8% HDPE Corrugated Pipes for Reliable Drainage Solutions

Understanding the Role of 8% HDPE Corrugated Pipe Manufacturers

High-density polyethylene (HDPE) corrugated pipes have gained significant traction in various sectors due to their outstanding versatility, durability, and cost-effectiveness. One of the crucial aspects of ensuring that these pipes perform optimally in a range of applications is relying on reputable manufacturers. In this article, we explore the importance of 8% HDPE corrugated pipe manufacturers, focusing on their contributions to infrastructure development, environmental sustainability, and technological advancements.

The Significance of HDPE Corrugated Pipes

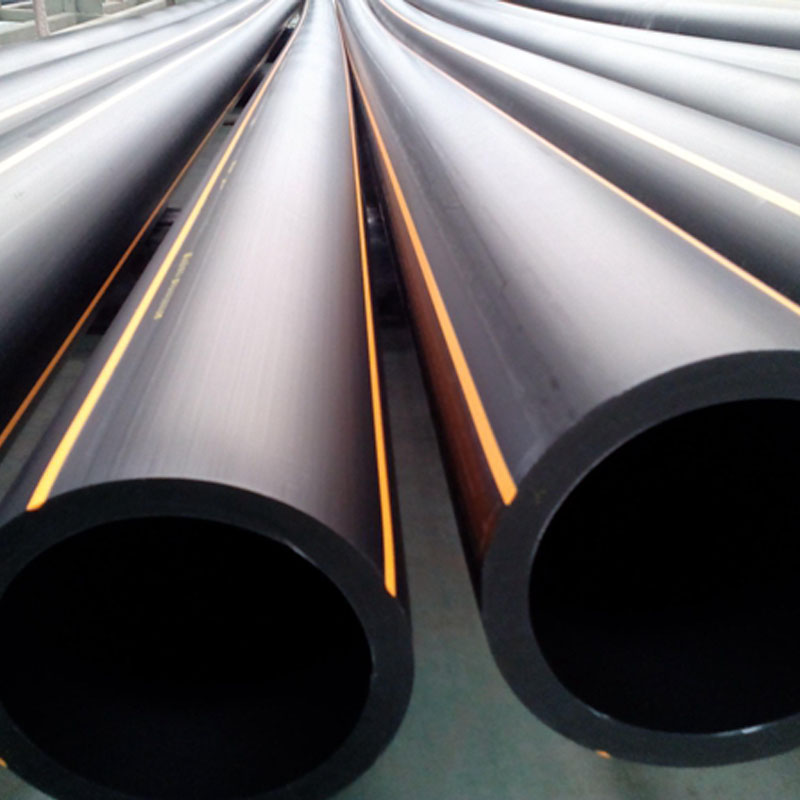

HDPE corrugated pipes are primarily utilized in drainage systems, stormwater management, and various industrial applications. The corrugated design enhances their strength and flexibility, making them ideally suited for underground utility installations. The 8% factor often refers to a specific material composition or design specification that meets industry standards, ensuring durability and resilience under pressure or adverse environmental conditions.

Manufacturers that produce 8% HDPE corrugated pipes adhere to stringent quality control measures and specifications to ensure that their products can withstand the rigors of use. Their involvement is critical, as the quality of the pipe directly impacts the efficiency and longevity of the installation.

Quality Assurance and Compliance

Renowned manufacturers invest in advanced technology and rigorous testing procedures to guarantee that their HDPE pipes meet or exceed regulatory standards. This commitment to quality assurance is vital for several reasons

1. Durability and Longevity High-quality HDPE pipes exhibit excellent resistance to corrosion, chemicals, and abrasion. By using superior manufacturing processes, manufacturers can produce pipes that last for decades with minimal maintenance.

2. Performance Under Stress 8% HDPE corrugated pipes are designed to perform efficiently under varying loads and conditions. Quality manufacturers conduct extensive testing to ensure that pipes can withstand environmental stresses, reducing the risk of costly failures.

3. Safety and Compliance In many regions, there are strict regulations governing construction materials. Manufacturers must ensure that their products meet local and international standards, thus guaranteeing safety and compliance throughout the construction lifecycle.

Environmental Impact

8 hdpe corrugated pipe manufacturer

Sustainability is a growing concern in manufacturing today. HDPE is known for its recyclability and lower carbon footprint compared to traditional materials like concrete and metal. Manufacturers of 8% HDPE corrugated pipes recognize their role in promoting eco-friendly practices.

1. Sustainable Sourcing Many manufacturers source HDPE from recycled materials, contributing to a circular economy and reducing waste in landfills.

2. Energy Efficiency The lightweight nature of HDPE pipes reduces transportation costs and emissions. Moreover, their installation typically requires less energy compared to heavier materials.

3. Water Conservation Corrugated pipes designed for drainage and stormwater management help manage water resources more efficiently, mitigating the impact of flooding and promoting groundwater recharge.

Technological Advancements

The evolution of HDPE technology continues to shape the industry. Innovative manufacturing techniques lead to improved pipe designs that enhance flexibility, strength, and resistance properties.

1. Smart Manufacturing Many manufacturers are adopting smart technology to streamline production processes. Utilizing data analytics and automation can improve efficiency and consistency in pipe production.

2. Research and Development By investing in R&D, manufacturers can develop new products that meet emerging needs in infrastructure projects, such as enhanced drainage capabilities or geothermal applications.

3. Collaboration and Partnerships Collaboration with civil engineers and urban planners ensures that the design and materials used in 8% HDPE corrugated pipes align with current and future project requirements.

Conclusion

The role of 8% HDPE corrugated pipe manufacturers is vital in shaping modern infrastructure. Their commitment to quality, environmental sustainability, and technological advancement ensures that these products meet the demands of today's projects while paving the way for a greener future. As construction continues to evolve, these manufacturers will remain at the forefront of innovation and sustainability, providing essential support for various applications worldwide.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025