Dec . 11, 2024 11:26 Back to list

8 hdpe corrugated pipe factory

The Significance of 8% HDPE Corrugated Pipe Factories

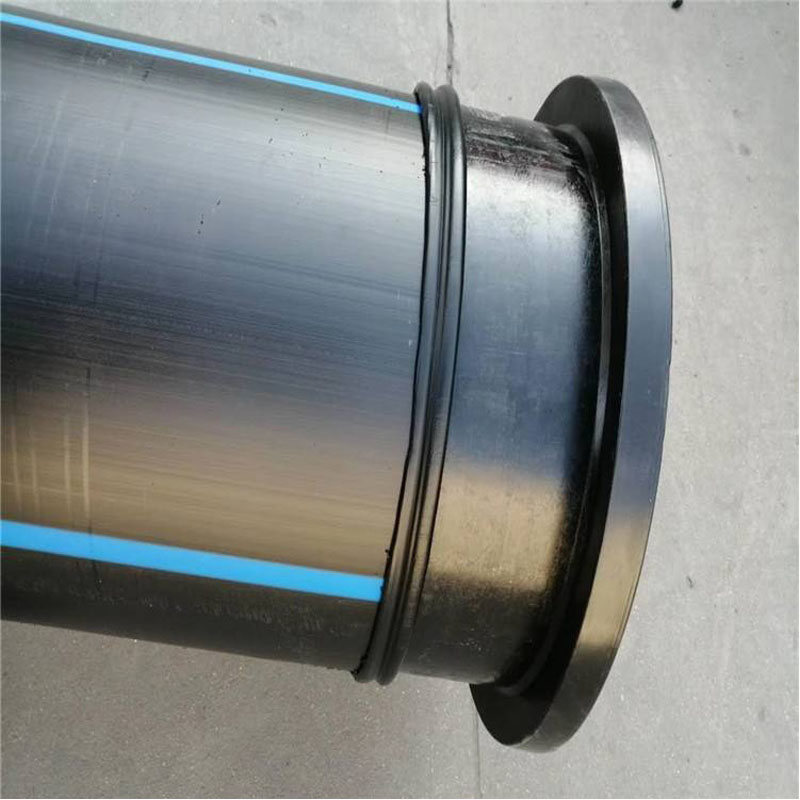

High-Density Polyethylene (HDPE) corrugated pipes have become a staple in the construction and drainage industries due to their strength, flexibility, and resistance to environmental factors. The rise of HDPE technology has led to increased productivity and efficiency in various sectors, and factories focusing on producing 8% HDPE corrugated pipes have emerged as key players in this market.

Understanding HDPE Corrugated Pipes

HDPE is a thermoplastic polymer made from petroleum. It provides numerous advantages, such as being lightweight, durable, and resistant to corrosion. Corrugated pipes, characterized by their wave-like structure, offer enhanced strength and load-bearing capabilities. The 8% in this context typically refers to the ratio of recycled materials utilized in the production process, making these pipes both environmentally friendly and cost-effective.

Benefits of 8% HDPE Corrugated Pipes

1. Environmental Sustainability The incorporation of recycled materials in the manufacturing process significantly reduces the demand for virgin resources. This aligns with global sustainability goals and promotes a circular economy. The use of HDPE also means these pipes are recyclable at the end of their lifespan, minimizing waste in landfills.

2. Durability and Longevity HDPE pipes are known for their exceptional resistance to rust, chemicals, and UV exposure. These properties allow them to withstand harsh environmental conditions, ensuring a longer service life compared to traditional materials like metal or concrete. Factories producing 8% HDPE corrugated pipes focus on maintaining high production standards to meet these demanding requirements.

3. Cost Efficiency The lightweight nature of HDPE pipes makes them easier to handle and transport, which can lead to significant savings in labor and shipping costs. Furthermore, their durability reduces the need for frequent replacements, providing long-term savings for consumers and businesses alike.

8 hdpe corrugated pipe factory

4. Versatility 8% HDPE corrugated pipes are used in various applications, including stormwater drainage, sewer systems, agricultural irrigation, and even in residential landscaping projects. Their adaptability to different environments makes them a preferred choice for engineers and architects.

The Manufacturing Process

Factories dedicated to producing 8% HDPE corrugated pipes follow stringent quality control measures to ensure consistency and performance. The manufacturing process involves several steps

1. Material Sourcing The first step is sourcing high-quality HDPE resin, alongside recycled materials to meet the 8% requirement. 2. Extrusion The HDPE is heated and extruded into a corrugated pipe shape using specialized machinery. This process allows for the precise formation of the pipe's structure. 3. Cooling and Cutting After extrusion, the pipes are cooled and cut to desired lengths. Quality checks are performed at multiple stages to ensure that the pipes meet industry standards.

4. Packaging and Distribution The finished products are then packaged for shipment to various markets, including construction companies, municipalities, and agricultural distributors.

Conclusion

The emergence of factories producing 8% HDPE corrugated pipes marks a significant step toward sustainable manufacturing and resource management. As industries continue to seek ways to reduce their environmental impact, these factories play a crucial role in providing an eco-friendly alternative to traditional piping solutions. With their durability, cost-effectiveness, and versatility, 8% HDPE corrugated pipes are likely to remain a prominent choice in various applications, contributing to the overall sustainability of the construction and drainage sectors. As technology advances and awareness of environmental issues increases, the demand for such innovative solutions will only grow, creating a bright future for HDPE corrugated pipe factories.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025