Sep . 28, 2024 15:31 Back to list

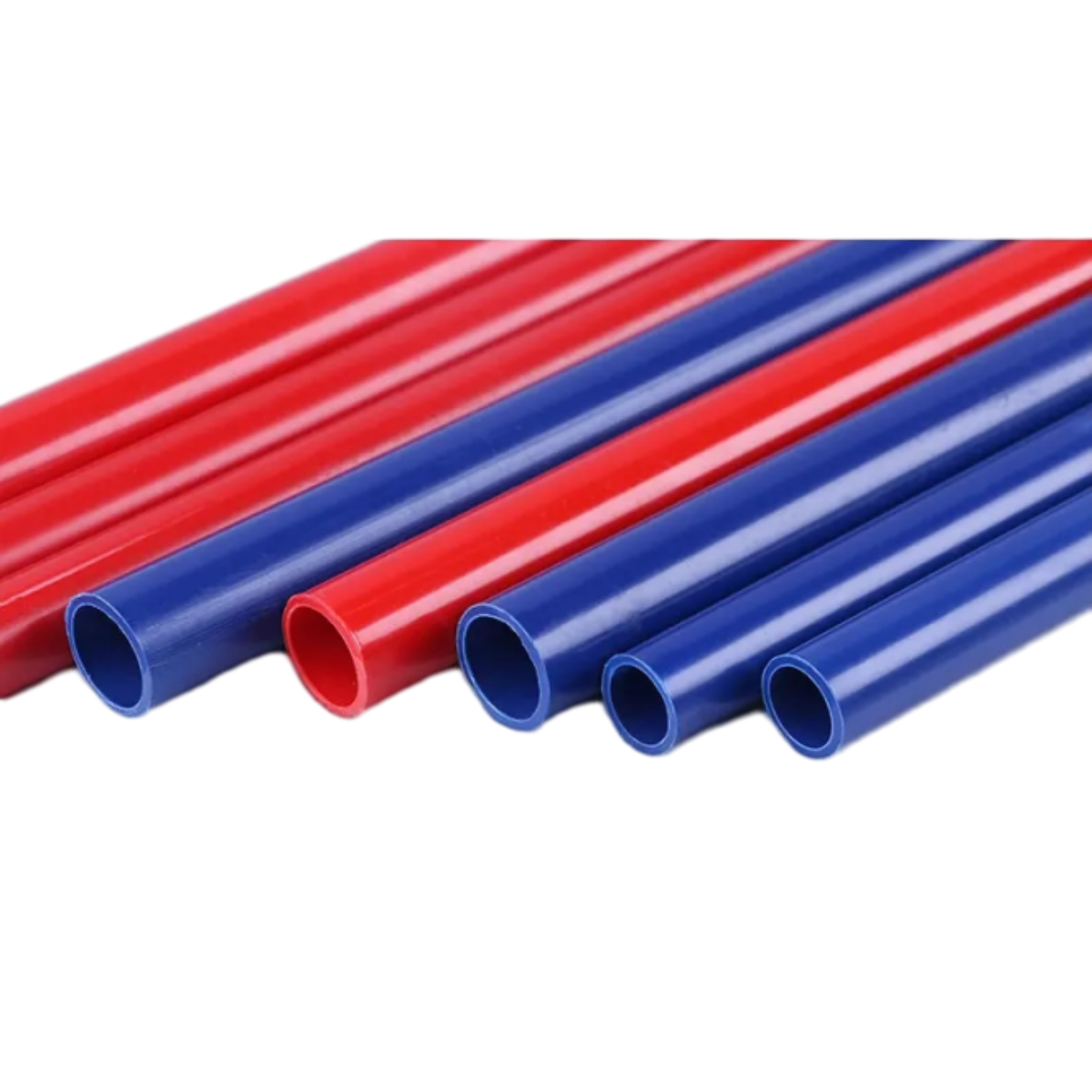

75mm PVC Pipe Suppliers and Manufacturers for Reliable Water Infrastructure Solutions

The Rise of 75mm PVC Pipe Manufacturers A Comprehensive Overview

In the modern era, the demand for versatile and durable piping solutions has ushered in a significant rise in manufacturers specializing in polyvinyl chloride (PVC) pipes. Among the various sizes available, the 75mm PVC pipe has gained notable attention for its adaptability in various applications, including agriculture, construction, and drainage systems.

Understanding PVC Pipes

Polyvinyl chloride, commonly referred to as PVC, is a type of plastic widely used in piping due to its lightweight, durability, and resistance to chemical corrosion. These pipes are available in various diameters and thicknesses, with the 75mm size being particularly popular for its balance between strength and manageability. This size is often used in both residential and industrial settings, making it a key player in the piping industry.

Applications of 75mm PVC Pipes

1. Agricultural Use One of the primary applications of 75mm PVC pipes is in agriculture. These pipes are frequently employed for irrigation systems, allowing farmers to efficiently manage water distribution. The durability of PVC ensures that these pipes can withstand the rigors of outdoor environments, including exposure to UV rays and varying weather conditions.

2. Construction and Civil Engineering In the construction sector, 75mm PVC pipes are commonly used for drainage systems and wastewater management. Their smooth interior walls facilitate the swift movement of water and refuse, reducing the likelihood of blockages. Additionally, their lightweight nature makes them easier to handle and install, saving both time and labor costs on construction sites.

3. Domestic Plumbing Homeowners also benefit from 75mm PVC pipes, as they are often used in plumbing systems for delivering water and removing wastewater. The resistance to corrosion and chemicals ensures a longer lifespan compared to traditional metallic pipes, thereby providing cost savings over time.

The Manufacturing Process

The process of manufacturing 75mm PVC pipes involves several critical steps. First, PVC resin is mixed with various additives to enhance the pipe's properties, such as flexibility and UV resistance. The mixture is then heated and extruded into the desired shape, followed by cooling and cutting to specified lengths. Quality control measures are integral throughout the manufacturing process to ensure the pipes meet industry standards and regulations.

75mm pvc pipe manufacturers

Challenges Facing Manufacturers

Despite the optimistic outlook for 75mm PVC pipe manufacturers, there are several challenges that need to be addressed. Environmental concerns regarding plastic waste have led to increased scrutiny of PVC products. Manufacturers are now focusing on sustainable practices, including recycling older pipes and utilizing more environmentally friendly additives in their production processes.

Another challenge is the fluctuating costs of raw materials. Global supply chain disruptions and political factors can affect the availability and pricing of PVC resin, impacting overall production costs. Manufacturers are now seeking alternative materials and more efficient production methods to mitigate these impacts.

Future Trends

The future of 75mm PVC pipe manufacturing looks promising, with a few key trends emerging. Firstly, there is a growing emphasis on innovation and technology in production methods. Manufacturers are investing in automated systems and robotics to enhance efficiency and reduce labor costs.

Secondly, the trend towards sustainability is expected to continue shaping the industry. As consumers and industries demand more environmentally friendly products, manufacturers are likely to adopt greener practices, such as using recycled materials and minimizing waste during production.

Lastly, the advent of smart technology in construction and infrastructure is opening up new avenues for PVC pipes. Sensors and smart systems integrated with plumbing networks could provide real-time data on water usage, leaks, and overall system health, further enhancing the value of PVC piping solutions.

Conclusion

In conclusion, the rise of 75mm PVC pipe manufacturers plays a crucial role in meeting the diverse needs of modern infrastructure. As applications continue to expand across various sectors, and as manufacturers tackle challenges through innovation and sustainability, the future of 75mm PVC pipes appears bright. This versatile piping solution will likely remain a staple in construction, agriculture, and plumbing for years to come, underlining the essential services provided by manufacturers in this sector.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025