Sep . 03, 2024 16:18 Back to list

63mm hdpe pipe price service

Understanding the Pricing and Services of 63mm HDPE Pipes

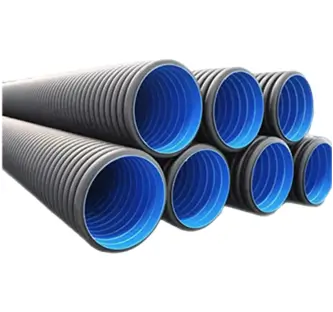

High-Density Polyethylene (HDPE) pipes have gained immense popularity in various industries due to their robustness, lightweight nature, and resistance to corrosion. Among the different sizes available, the 63mm HDPE pipe plays a significant role in infrastructure projects, especially in water supply, irrigation, and drainage systems. This article delves into the pricing dynamics and the accompanying services related to 63mm HDPE pipes.

Factors Influencing Pricing

Several factors contribute to the price of 63mm HDPE pipes. Firstly, the raw material costs greatly influence the pricing. The price of polyethylene, a key component in HDPE pipe manufacturing, can fluctuate based on global oil prices and supply chain dynamics. Hence, when assessing the price of 63mm HDPE pipes, one must consider these external economic factors.

Moreover, production methods and technology employed by manufacturers play a pivotal role in determining the price. Companies utilizing advanced machinery and processes may incur higher initial setup costs but can produce high-quality pipes with enhanced durability, leading to better long-term value for consumers.

Additionally, the geographic location of the manufacturing facility can affect prices due to transportation costs

. Pipes produced closer to the point of sale typically incur lower shipping fees, providing a competitive edge in pricing.Average Pricing

While the average cost may vary depending on the above factors, as of October 2023, the price range for 63mm HDPE pipes generally falls between $0.50 to $3.00 per meter. This cost can be further influenced by factors like bulk purchasing discounts, regional market competition, and seasonal demand spikes.

63mm hdpe pipe price service

Accompanying Services

When purchasing 63mm HDPE pipes, it's essential to consider not just the pipe itself but also the range of services provided by manufacturers and distributors. Key services can include

1. Installation Support Many suppliers offer guidance or professional installation services, ensuring that the pipes are laid correctly and efficiently. 2. Custom Fabrication Depending on project requirements, manufacturers may provide custom lengths or fittings, catering to specific site needs. 3. After-Sales Support Reliable after-sales service is vital. Suppliers often offer warranties or support services to address any issues with the pipes once they are in use.

4. Consultation Services Experts in the field can assist in the selection of the right type of HDPE pipe for specific applications, taking factors like pressure ratings, environmental conditions, and intended use into account.

5. Sustainability Practices With increasing awareness around sustainability, many manufacturers are now emphasizing eco-friendly practices in both production and recycling of HDPE pipes, thereby enhancing their market appeal.

Conclusion

The 63mm HDPE pipe offers various advantages for infrastructural needs, coupled with a competitive price range influenced by several distinct factors. When selecting supplies for your next project, it is crucial to consider not only the pricing but also the comprehensive services that vendors offer, ensuring a smooth and successful installation and maintenance process. As industries continue to evolve, the demand for quality HDPE pipes and reliable services will only increase.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025