Mar . 02, 2024 12:17 Back to list

What to Know When Selecting Water Pipes

Water intake pipes – those that distribute water to the faucets and fixtures inside our homes and buildings – are different from a lot of other building materials as they are one of the only materials that come directly into contact with the water that we drink, cook with, and wash with everyday. The materials we use to deliver our drinking water matter to our health and the health of our planet, and HBN recently released a new Water Pipes Hazard Spectrum comparing the impacts of different materials used for interior water intake pipes from a health perspective.

As with most product decisions, tradeoffs exist and must be considered. In the final analysis we favor copper joined without solders, fluxes, or other filler metals in most situations1 over the plastic alternatives. Despite environmental health impacts associated with copper mining and smelting, the evidence suggests fewer concerns than plastic products during the use phase and at the end of life.

The Water Pipes Hazard Spectrum

You can use the HBN Water Pipe Hazard Spectrum to benchmark your current practice and take a step up to healthier options. Products in green categories are typically the better options, whereas products at the bottom of the spectrum, in shades of red, are to be avoided. Those in-between provide intermediate options from a health hazard perspective. Read on to learn more about our guidance, and see our full Pipes Hazard Spectrum for more information.

Note that our research was limited to interior intake pipes, and therefore our findings and recommendations are not intended to be applied to pipes outside of buildings, or pipes that carry waste water out of the building. Our recommendations should be seen as a supplement to, and not a replacement for, the guidance that already exists to address the real issue of contaminated drinking water supplies that many communities face.2 (See end of article for resources on external water pipes.)

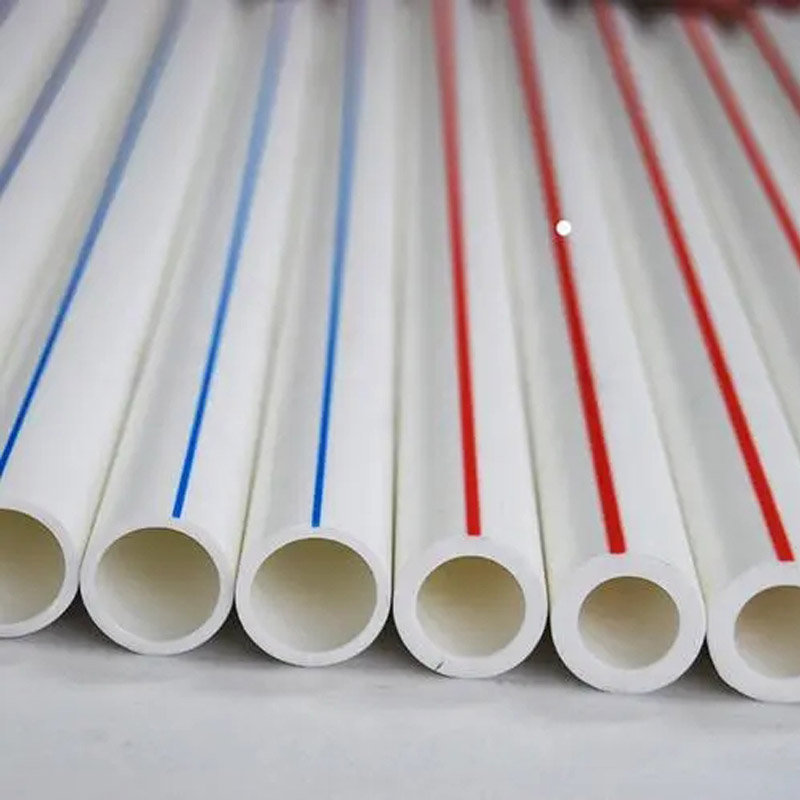

DN25 PPR water pipes for kitchen

Health and Environmental Impacts

The global plumbing pipes and pipe fittings market is worth $11.8 billion USD in 2021 and continues to grow, driven both by new construction and repairs.3 Water intake pipes can be made from copper or a range of plastic materials, and each has pros and cons when comparing the impacts to human health and the environment.

Manufacturing Impacts

COPPER

Copper mining can have substantial negative impacts on the surrounding communities. Copper mines can release hazardous industrial waste, such as sulfuric acid, into waterways and into the air. These releases can harm the health of people living nearby, and also can damage nearby crops and corrode buildings.4

One positive characteristic of copper is that it has the potential to be recycled, aligning better than plastic with circular economy principles. Copper pipes are generally made up of 40-80% recycled copper, reducing the need to mine virgin copper, and by extension its environmental impacts.5

PLASTIC

Plastic pipes are typically one of the following varieties, each of which having its own environmental impacts:

- Polyvinyl chloride (PVC)

- Chlorinated polyvinyl chloride (CPVC)

- Polypropylene (PP)

- High density polyethylene (HDPE)

- Crosslinked polyethylene (PEX)

All plastic pipes are made from petroleum, carrying forward the fossil fuel’s associated impacts such as carbon emissions during extraction, transport, feedstock refining, and manufacture. A new Shell plant in Pennsylvania, for example, will emit the equivalent of ~ 2.25 million tons of carbon dioxide each year - equal to adding almost 500,000 new cars to the road. Multiply that by the 300 new and expanded petrochemical projects being built in the US alone—primarily for the production of plastic and plastic feedstocks—and you have an enormous environmental issue.6

Product Use Impacts

When drinking water comes into contact with pipes, they can release chemicals into the water. In general, plastic pipes require the use of more chemicals in their manufacture than copper pipes, and some of these chemicals can leach from the pipes or break down into other chemicals that leach from the pipes.7 For example, PVC and CPVC pipes are manufactured with organotin stabilizers that are toxic to the reproductive system and can leach into drinking water.8

While standards, such as NSF International Drinking Water standards, set acceptable levels of certain chemicals that leach out of pipes and pipe components,9 these tests and standards have limitations. For instance, the standards do not consider the combined impacts of multiple chemical exposures that all people experience.10 One additional limitation is that under U.S. federal law, plumbing fixtures and fittings can contain up to 0.25% lead by weight, and solders and fluxes (components used to join pipes together) can contain up to 0.2% lead by weight and still be labeled “lead free.”11 Labeling components as “lead free” that actually contain lead is concerning because numerous authoritative bodies agree that there is no safe level for exposure to lead.12

End of Life Impacts

While most types of pipes aside from PEX are technically recyclable, in actuality copper is the only pipe that both is made of recycled content (40-80%) and is likely to be recycled at the end of its life (40-50% global recycling rate for copper).13 This makes copper a better choice to support a circular economy.

What is the best choice?

While there are real and significant tradeoffs to consider, the best way to avoid hazards throughout the pipe life cycle and to support circularity is to:

- Prefer copper pipes installed without solders, fluxes, or other filler metals. After installation, copper pipes have the fewest health hazards, but many solders and fluxes used to join pipes contain lead and other heavy metals of concern. “Lead-free” solders are still allowed to contain a small amount of lead under federal regulations.

- Avoid using copper pipes if your water supply typically has a low pH (<6.5). Such conditions can be present in water supplied from some private wells, and can cause copper pipes to corrode, releasing copper ions into the water.14 Consuming high concentrations of copper is linked to a number of health effects including liver and kidney damage.15

- If plastic pipes are selected, choose polypropylene (PP) or high density polyethylene (HDPE) over crosslinked polyethylene (PEX). In general, plastic pipes require the use of more chemicals in their manufacture than metal pipes, and some of these chemicals can leach from the pipes or break down into other chemicals that leach from the pipes into water.16 Higher levels of chemicals may leach from PEX pipes than from PP and HDPE. In addition, PEX pipes cannot be recycled into new pipes at their end of life.

- Avoid using polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC). These pipes contain the highest levels of chemicals of concern and they are typically installed using hazardous solvents.

- Prefer products with full disclosure of content through Health Product Declarations (HPDs). In general, water pipes have very poor content disclosure. Encourage manufacturers to fully disclose the content and associated health hazards of water pipes through the industry’s collaborative, user-designed open standard, Health Product Declarations (HPD).

Conclusion

Water pipes carry one of the most valuable resources into our homes, workplaces, and communities. While there are no water pipes free of impacts, HBN’s new Water Pipe Hazard Spectrum provides a simple way to benchmark your current practice and take a step up to the better choices available on the market today. We hope to see continued innovation in the field of water pipes to provide increasingly healthier and safer solutions.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025