Dec . 10, 2024 01:41 Back to list

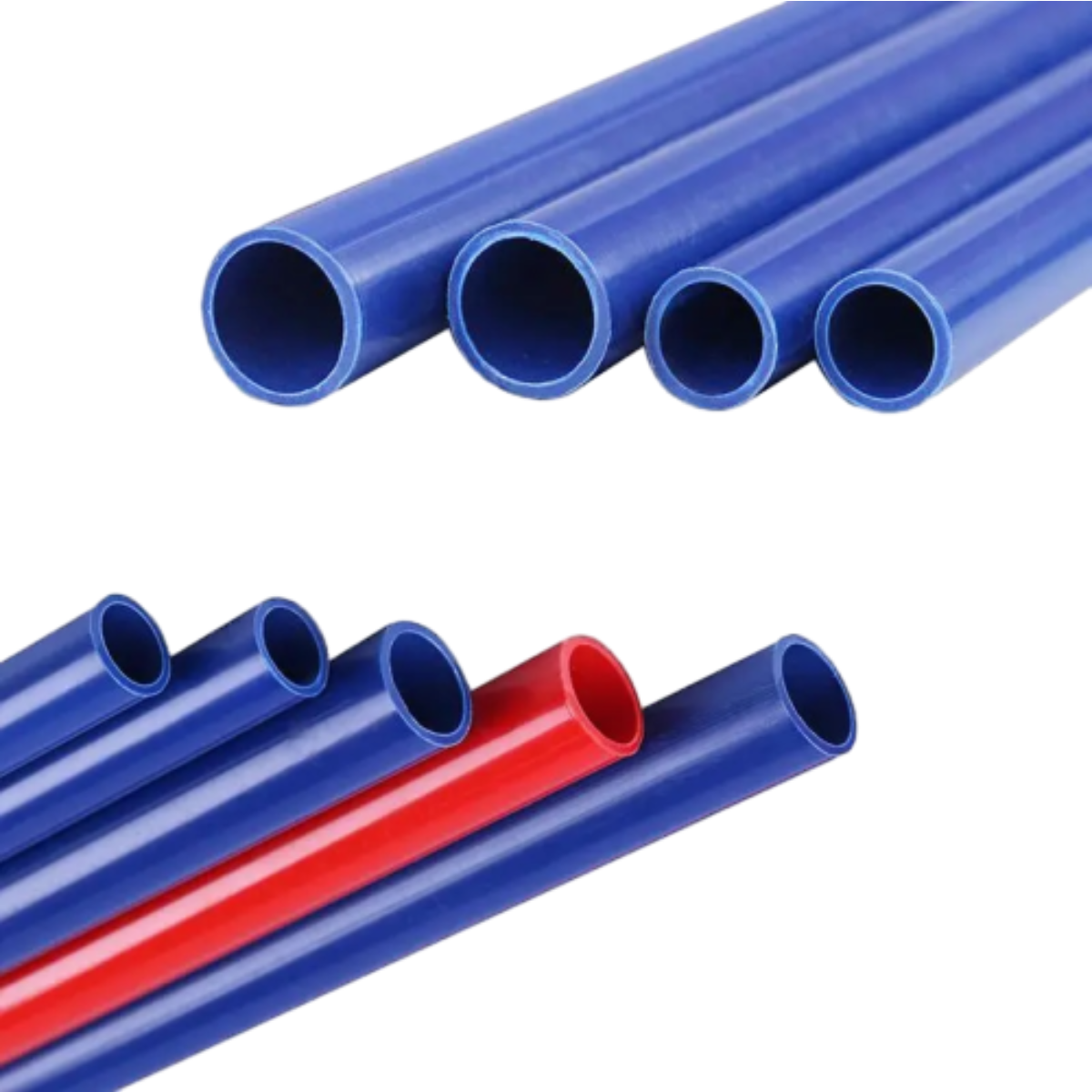

High-Quality 50mm PPR Pipe Manufacturer for Reliable Plumbing Solutions

Understanding 50mm PPR Pipe Insights from the Factory Floor

In the realm of plumbing and construction, the choice of piping materials is crucial for ensuring longevity, efficiency, and safety. One popular option that has gained traction in recent years is the 50mm PPR (Polypropylene Random Copolymer) pipe. This article explores the characteristics, manufacturing processes, and benefits of 50mm PPR pipes, as observed from the factory perspective.

What is PPR Pipe?

Polypropylene Random Copolymer (PPR) pipes are thermoplastic pipes made from a type of polypropylene, which is known for its excellent chemical resistance, durability, and versatility. PPR pipes are commonly used in both hot and cold water supply systems and are favored for their lightweight nature and ease of installation. The 50mm diameter is a standard size that caters to a variety of applications, from residential plumbing to industrial uses.

Manufacturing Process of 50mm PPR Pipes

The production of 50mm PPR pipes is a meticulous process that takes place in highly specialized factories. Here’s a closer look at the manufacturing stages

1. Raw Material Preparation The process begins with the selection of high-quality polypropylene granules. These raw materials are critical to ensuring the pipes' strength and durability. Factories source their materials from reputable suppliers, as the quality of polypropylene directly impacts the final product's performance.

2. Extrusion The next step involves feeding the polypropylene granules into an extruder. Here, they are heated to a specific temperature until they melt and become pliable. The melted material is then forced through a die that shapes the pipe to a 50mm diameter. This stage is crucial as it determines the pipe's wall thickness and seal integrity.

3. Cooling and Cutting After extrusion, the continuous length of pipe passes through a cooling system where it is cooled down to solidify its structure. The cooled pipes are then cut into specified lengths, ready for packaging.

4. Quality Control Quality assurance is a central focus in the manufacturing process. Each batch of 50mm PPR pipes undergoes rigorous testing, including pressure testing, to ensure they meet industry standards. Factories often have in-house laboratories equipped to assess the pipes' resistance to high temperatures and pressures, as well as their durability over time.

50mm ppr pipe factory

5. Packaging and Distribution Once the pipes pass quality checks, they are packaged for distribution. Many factories strive for eco-friendly packaging solutions, recognizing the importance of sustainable practices in today's manufacturing world.

Benefits of 50mm PPR Pipes

The popularity of 50mm PPR pipes among contractors and builders can be attributed to numerous benefits

- Durability PPR pipes are resistant to various chemicals and do not corrode, making them an excellent choice for long-term applications. They also withstand high temperatures, making them suitable for hot water systems.

- Ease of Installation The lightweight nature of PPR pipes allows for easy handling and installation. Furthermore, they can be easily fusion-welded, creating strong, leak-proof joints without the need for additional fittings.

- Cost-Effectiveness Over their lifespan, 50mm PPR pipes can prove to be more economical than traditional materials like metal. Their longevity reduces the need for frequent replacements, while their thermal insulation properties can lead to lower energy costs for heating.

- Environmental Impact PPR is fully recyclable, aligning with modern sustainability goals. Factories are increasingly implementing practices to minimize waste during production and promote the recycling of used pipes.

Conclusion

In summary, 50mm PPR pipes represent a significant advancement in plumbing technology, offering a reliable and economical solution for a multitude of applications. The factory processes behind their manufacturing ensure that they meet high standards of quality and performance, making them a preferred choice among professionals in the construction industry. As demand for sustainable and efficient building materials continues to grow, 50mm PPR pipes are poised to play an essential role in the future of plumbing and infrastructure development.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025