Nov . 25, 2024 15:28 Back to list

Convert 4% HDPE to PVC Coupling for Reliable Connections in Plumbing Applications

Understanding 4% HDPE to PVC Coupling A Comprehensive Overview

In the world of plumbing and construction, the choice of materials is crucial for ensuring the longevity and efficiency of systems. One common coupling seen in various applications is the 4% HDPE (High-Density Polyethylene) to PVC (Polyvinyl Chloride) coupling. This coupling is significant for connecting pipes made from different materials, offering a solution that caters to specific service requirements.

What is HDPE?

High-Density Polyethylene (HDPE) is a thermoplastic derived from petroleum. Known for its high strength-to-density ratio, HDPE is commonly used in plastic bottles, corrosion-resistant piping, and plastic lumber. What makes HDPE particularly advantageous is its flexibility, resistance to impacts, and low moisture absorption, which contribute to its suitability in a variety of applications.

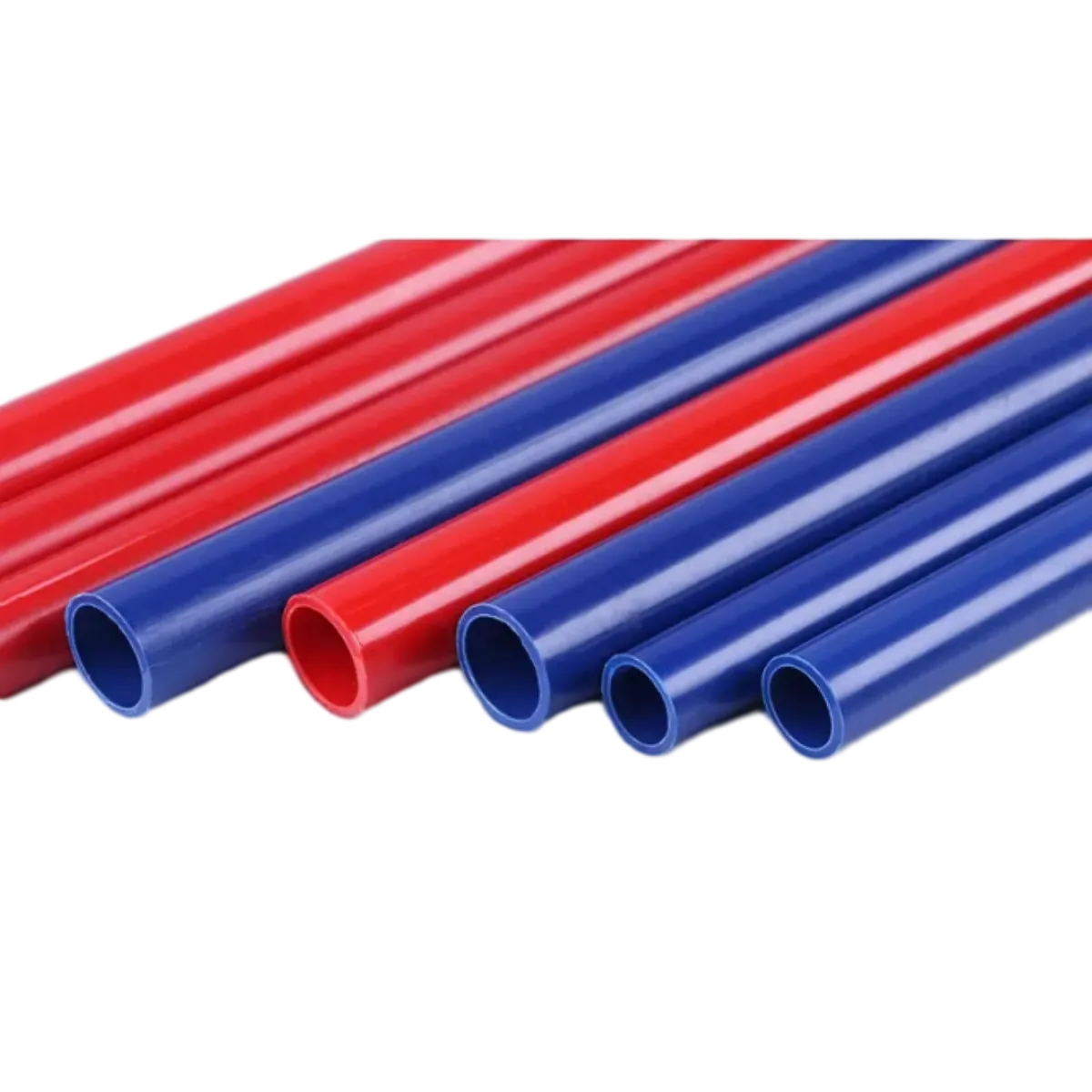

What is PVC?

Polyvinyl Chloride (PVC) is another widely used plastic, particularly in construction and plumbing. PVC is known for its rigidity and excellent resistance to chemicals, making it an ideal choice for piping systems. It is lightweight and easy to install, and due to its durability, PVC pipes are commonly utilized in sewage systems, drainage, and potable water services.

Importance of Coupling in Plumbing

Couplings are essential components in plumbing and piping systems, acting as connectors between different pipe sections or materials. They enable the extension of pipelines, facilitate changes in direction, and allow for the integration of various materials without compromising the integrity of the system. The 4% HDPE to PVC coupling is specifically designed to connect HDPE pipes with PVC components efficiently.

The Advantages of 4% HDPE to PVC Coupling

4 hdpe to pvc coupling service

2. Durability Both HDPE and PVC are known for their strength and resilience. The coupling system ensures that the connection can withstand the pressures typically encountered in plumbing applications.

3. Leak Resistance Properly fitted couplings minimize the risk of leaks, a critical factor in any plumbing system. The secure connection helps maintain fluid integrity and prevents contamination.

4. Cost-Effectiveness By combining different materials, project managers can optimize costs, using HDPE where flexibility is required and PVC for rigidity. This strategic choice can lead to overall savings in material procurement and installation.

5. Ease of Installation The design of the 4% HDPE to PVC coupling facilitates quick and easy installation, reducing labor time and costs associated with complex piping transitions.

Applications

This coupling is commonly utilized in various applications, including irrigation systems, municipal water supply, and even industrial processes where a combination of materials is necessary to meet service requirements.

Conclusion

The 4% HDPE to PVC coupling plays a pivotal role in modern plumbing and piping systems, allowing for the seamless integration of materials while ensuring durability, cost-effectiveness, and high performance. In a sector where material integrity is paramount, understanding and utilizing such couplings can lead to significantly improved outcomes. Choosing the right coupling system enhances the efficiency and reliability of plumbing installations, making it an indispensable component in today’s construction landscape.

-

High-Quality PVC Borehole Pipes Durable & Versatile Pipe Solutions

NewsJul.08,2025

-

High-Quality PVC Perforated Pipes for Efficient Drainage Leading Manufacturers & Factories

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Durable Pipe Solutions by Leading Manufacturer

NewsJul.08,2025

-

High-Quality PVC Borehole Pipes Reliable PVC Pipe Manufacturer Solutions

NewsJul.07,2025

-

High-Quality UPVC Drain Pipes Durable HDPE & Drain Pipe Solutions

NewsJul.07,2025

-

High-Quality Conduit Pipes & HDPE Conduit Fittings Manufacturer Reliable Factory Supply

NewsJul.06,2025